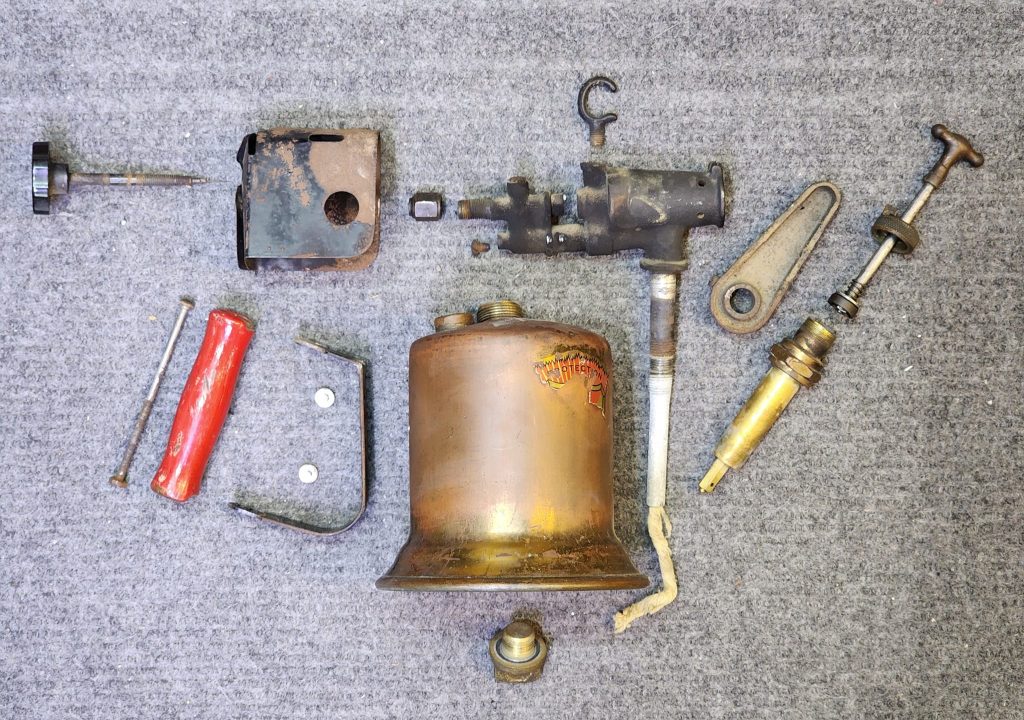

I was in need of a soldering iron hook for my past torch restoration of the Bernz so I picked this up, and well one thing led to another and here we are, the video below the pictures will go into more detail. But first how it looked when I picked it up!

It was now time to tear into it, to see what I was working with.

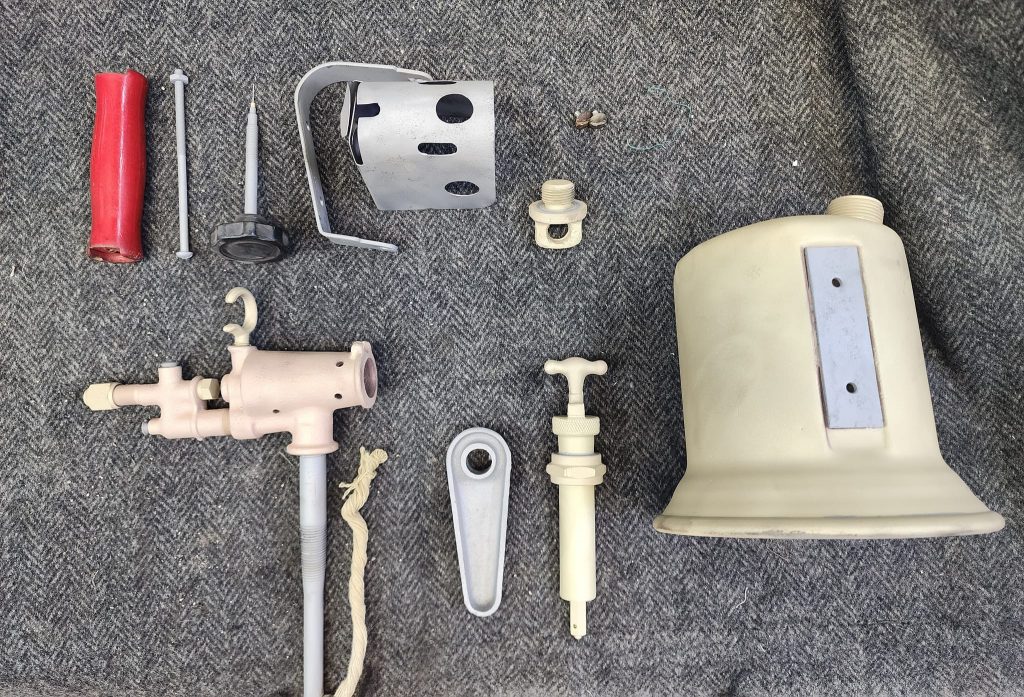

Lots of parts! The next photo set will be going through part by part to sand blast, than wire wheel, than polish to bring back the original shine. There is about 8 hours of constant work in these steps below.

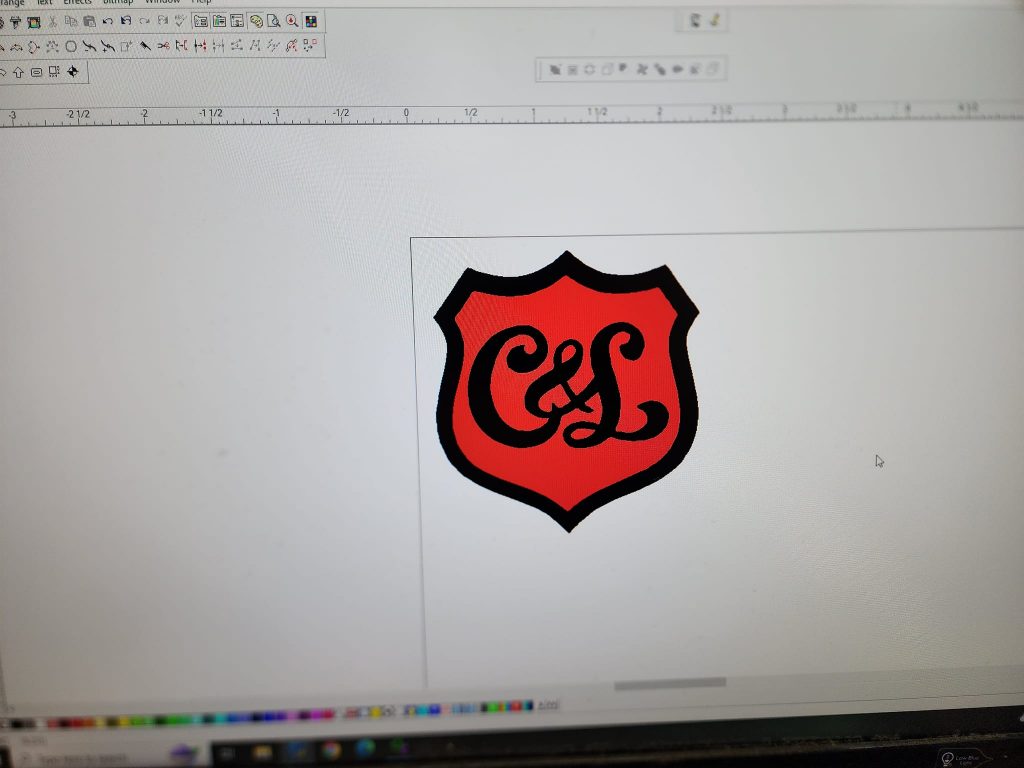

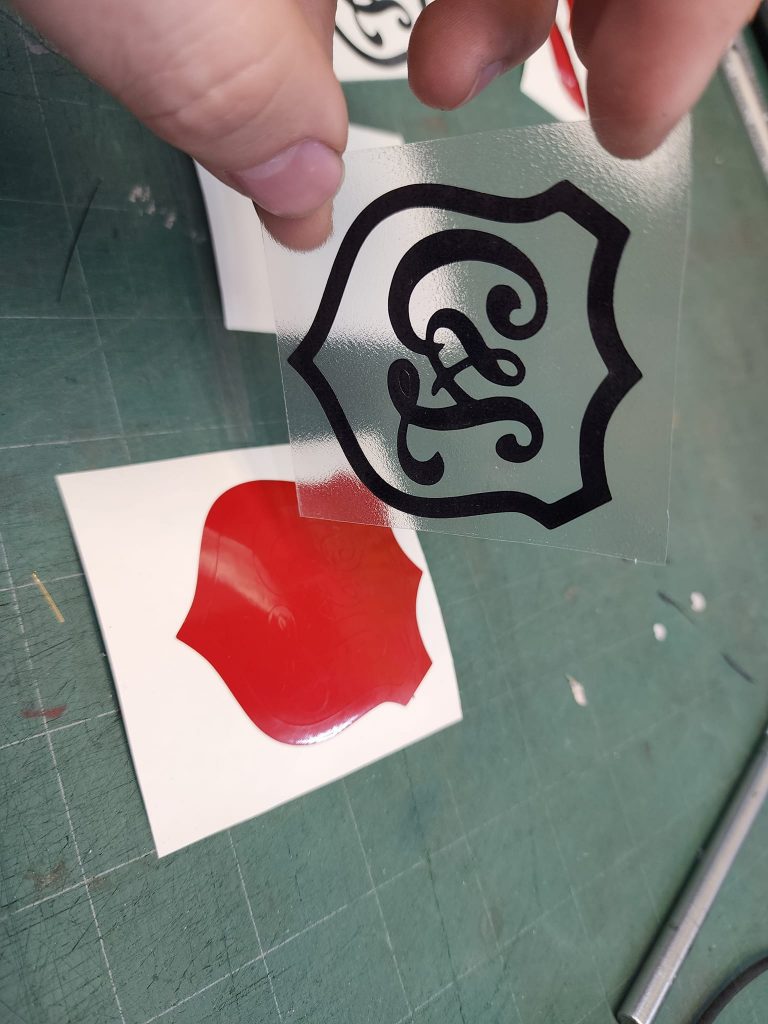

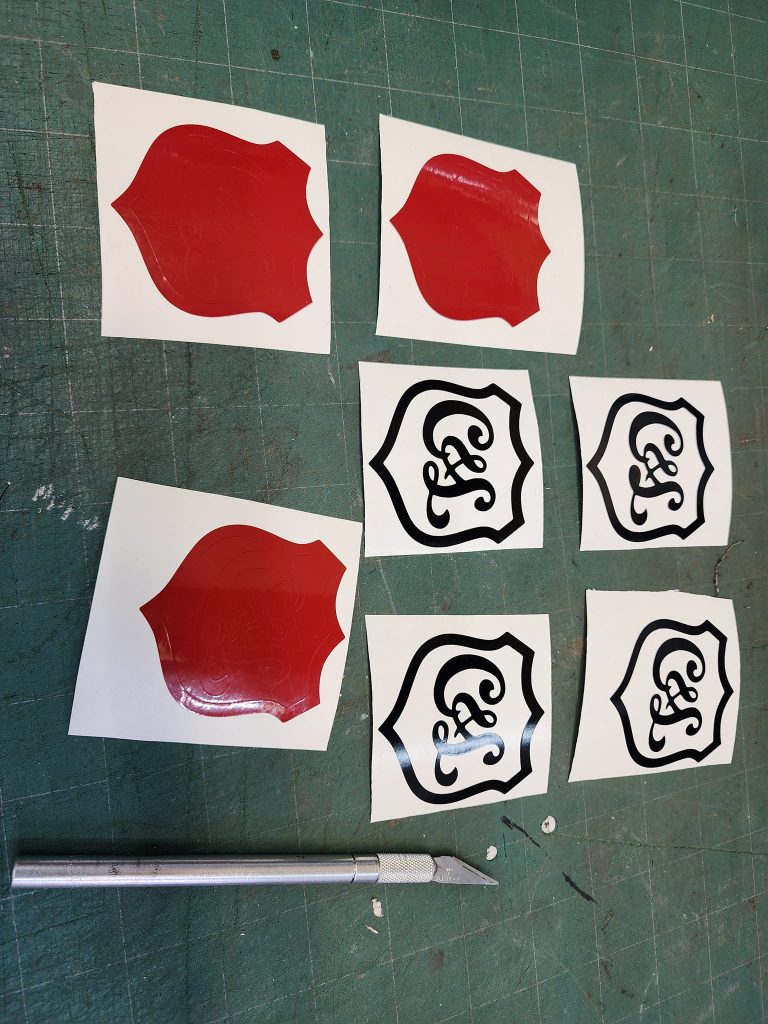

The one part that was bugging me the most was the missing logo! the original period correct logo for this torch would have been very hard for me to make from scratch, so I looked to see what their modern logo looked like, that it was much simpler to cut from vinyl, so I went resto mod, and put their new logo on their old torch, I love how it looks!

Now here is a video explaining what all I discovered!

And here are the finished photos!

The Clayton and Lambert Manufacturing Company, founded in 1888, was known for its high-quality torches and soldering equipment. By the early 20th century, they had established themselves as leaders in the field, producing torches that were both reliable and efficient. The 1921 model is a prime example of their ingenuity and dedication to excellence.

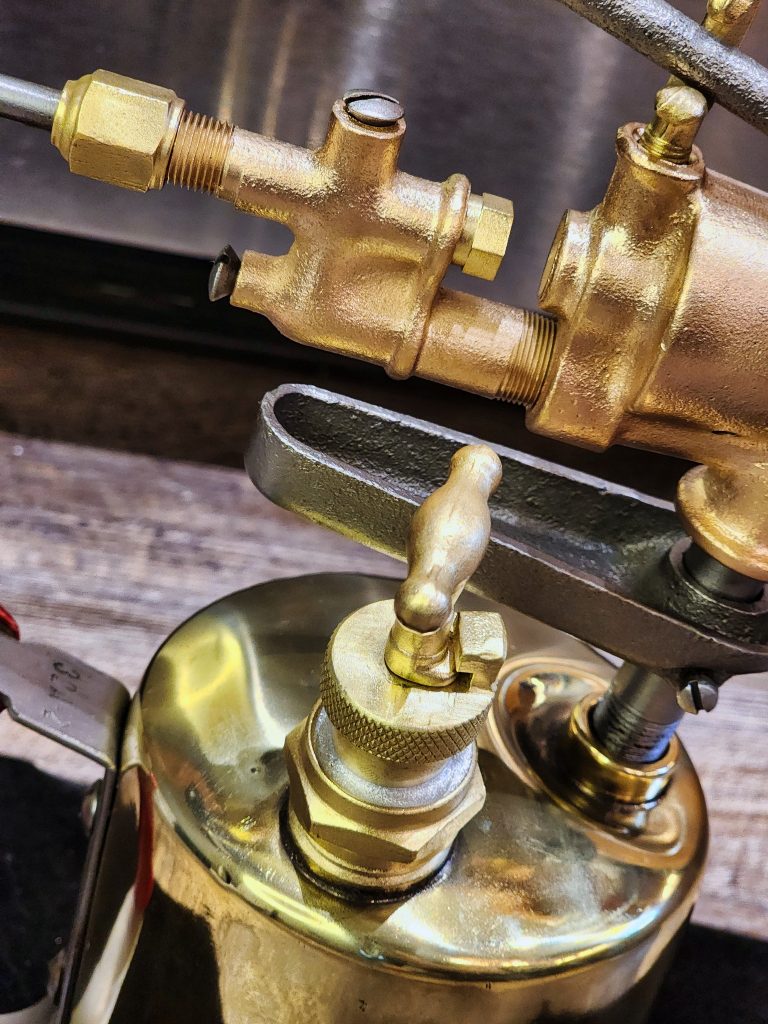

The torch itself is a beautifully crafted piece of machinery. Made primarily of brass and steel, it has a sturdy, industrial aesthetic that speaks to its durability and functionality. The design of the 1921 Clayton and Lambert torch was advanced for its time, incorporating a preheating system that allowed it to reach high temperatures quickly and maintain a consistent flame. This made it an indispensable tool for a variety of applications, from plumbing and metalworking to automotive repairs.

Using the torch required a bit of skill and knowledge. The process began by filling the fuel tank with gasoline or kerosene, then pumping air into the tank to create pressure. Once the fuel was pressurized, it was released into the burner, where it mixed with air and ignited to produce a hot, steady flame. The torch’s adjustable nozzle allowed the user to control the flame’s intensity, making it versatile enough for delicate soldering work or heavy-duty metal cutting.

The history of the Clayton and Lambert torch is intertwined with the rapid industrialization of the early 20th century. As industries grew and technology advanced, the demand for reliable, efficient tools skyrocketed. The 1921 torch met this demand head-on, becoming a staple in workshops and factories across the country. Its robust construction and innovative design set a standard for quality that many other manufacturers aspired to achieve.

One of the most notable uses of the Clayton and Lambert torch was in the automotive industry. As cars became more common, the need for effective tools to repair and maintain them grew. The torch’s ability to quickly heat and manipulate metal made it ideal for tasks such as soldering radiator seams, repairing exhaust systems, and even cutting through stubborn bolts. It’s not an exaggeration to say that this torch helped keep America’s early automobiles on the road.

Reflecting on the history and use of the 1921 Clayton and Lambert torch, I am struck by the craftsmanship and ingenuity that went into its creation. Holding this torch in my hands, I can’t help but appreciate the skill and dedication of the workers who built it and the countless tradespeople who relied on it. It’s a powerful reminder of a time when tools were made to last, and quality was paramount.

Today, the Clayton and Lambert torch is a cherished collector’s item, prized for its historical significance and enduring functionality. It stands as a symbol of an era of innovation and hard work, a tangible link to the craftsmen and industries that shaped the modern world.