As part of my day job, I am often designing and building custom electonics. With those electronics it is nice to have a clean way to mount and wire them. I often have to wire up and build and test the electronics before the cabinets have been built. So I came up with this system, that allows me to layout, mount and wire the electronics, with a harness that can be bolten in on day of install.

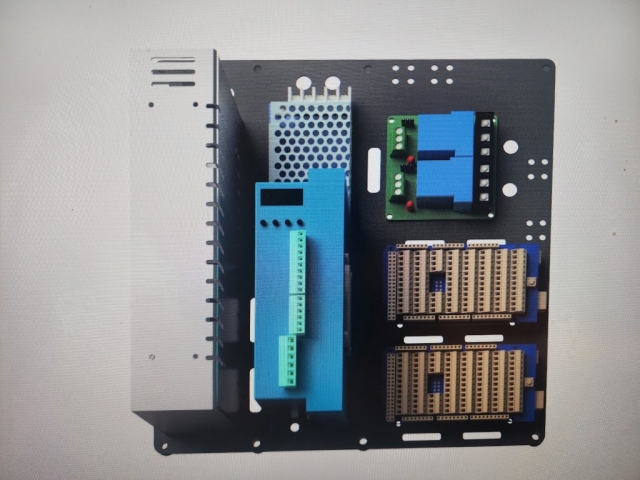

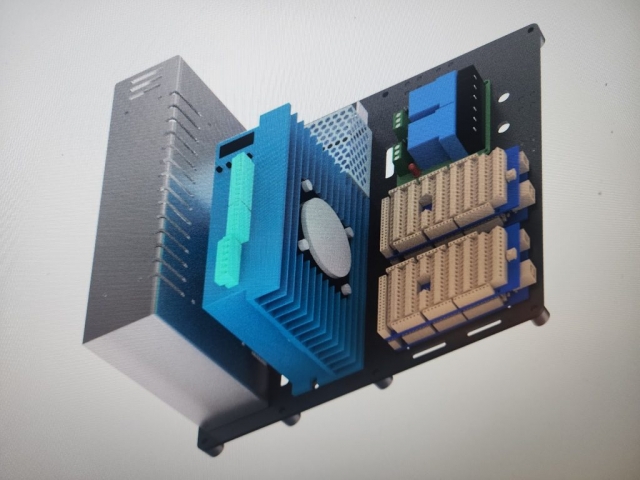

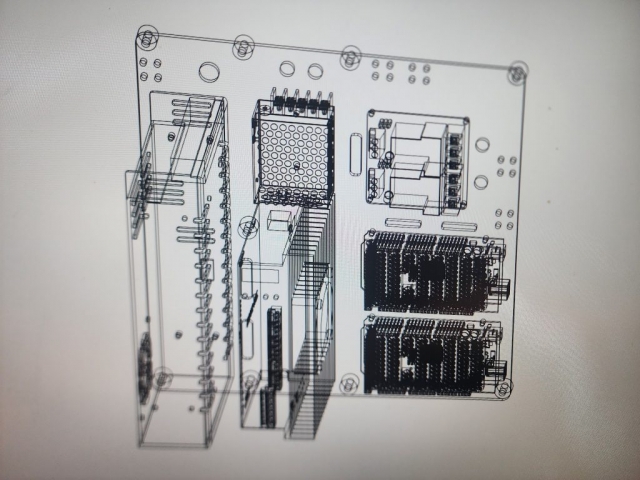

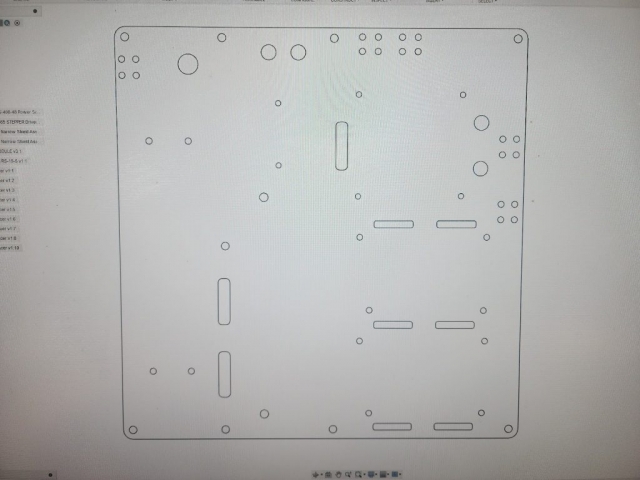

It all starts in the computer where I make a 3D model of all the components I need to mount. To figure out how best to lay them out so I have access to everything. And it is still servicable.

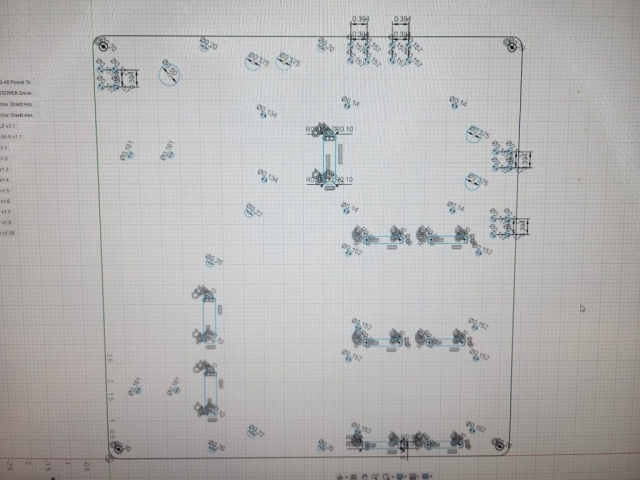

From there, I mark the locations of every place I need wires to run and make up a DXF of the cutouts.

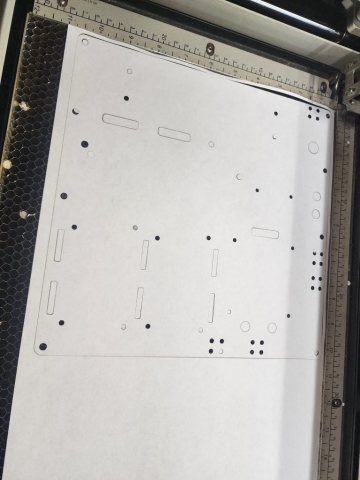

From there I take it to our laser cutter, I start with Paper to make sure all my measurements will work.

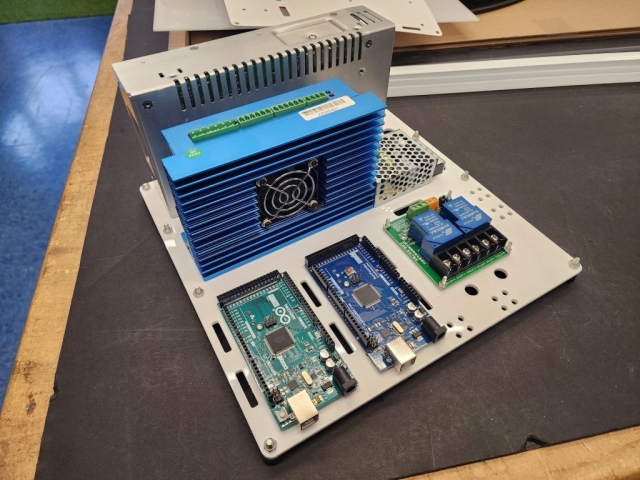

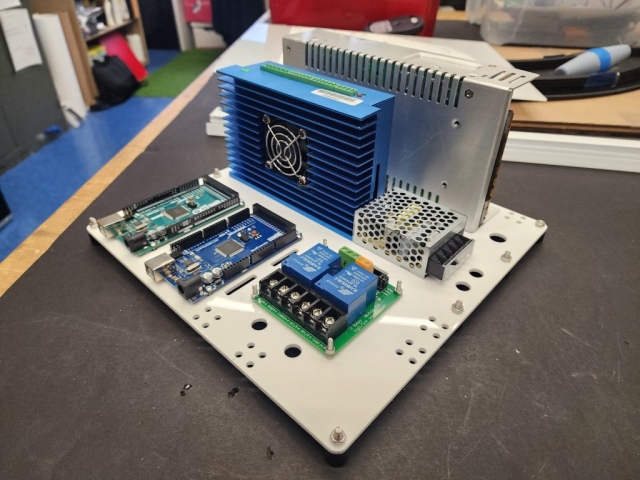

Now to test fit everything!

Looking like it will work! Now to cut it out from 1/8″ Plex.

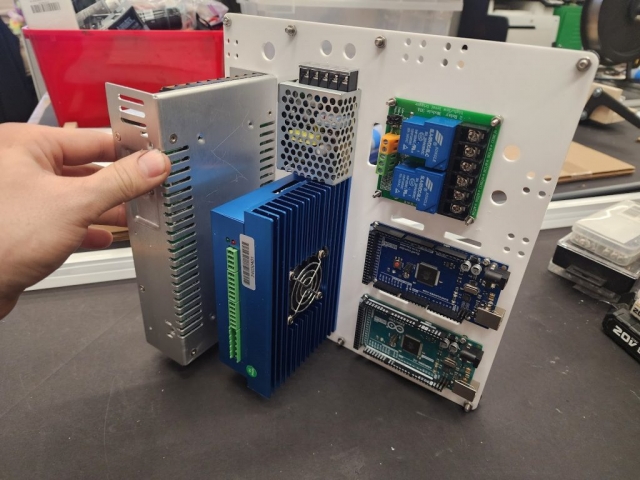

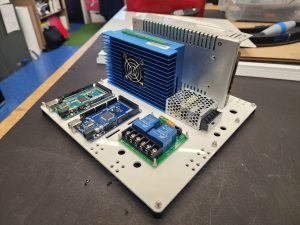

Everything fit perfectly! I added extra suport mount holes around the power supply and Stepper driver to keep it from flexing when mounted.

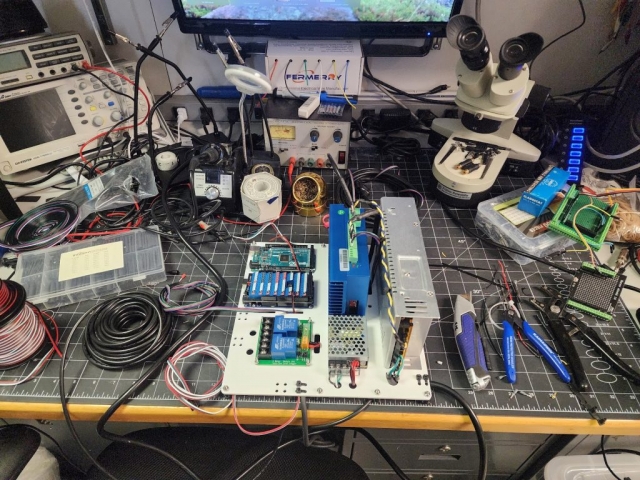

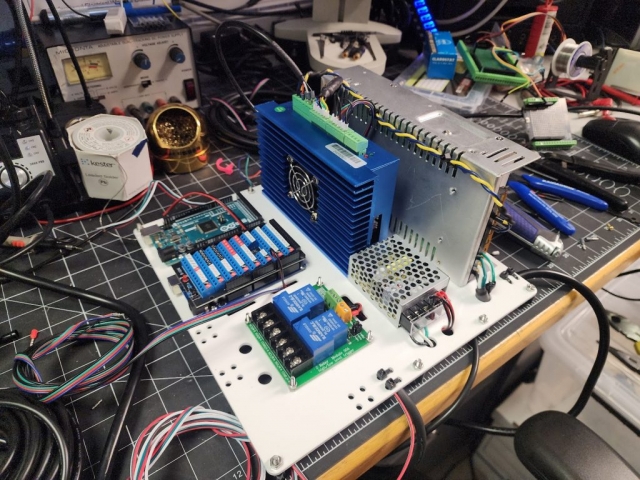

It looks like a disaster at the moment, but working my way through final wiring. When finished and installed will update this post!

The small set of holes around the edge are for zip ties, to lock the wires in that go out as part of each harness. They will all have plugs on the, for quick field connection.