So … I would never have bought a ‘Hazard’ Freight welder, but a few things came together to make me get this one. 1. Price, with a super coupon I was able to get this thing for $160~ and is a 170Amp 220V welder. 2. It is not made by Harbor Freight, it is a Re skinned Clarke welder they went out of business, this is old stock from those welders they bought up and re branded. It has guts made in Italy. 3. I can make it better…. Pics will have descriptions on what I did.

Size comparison. Comments

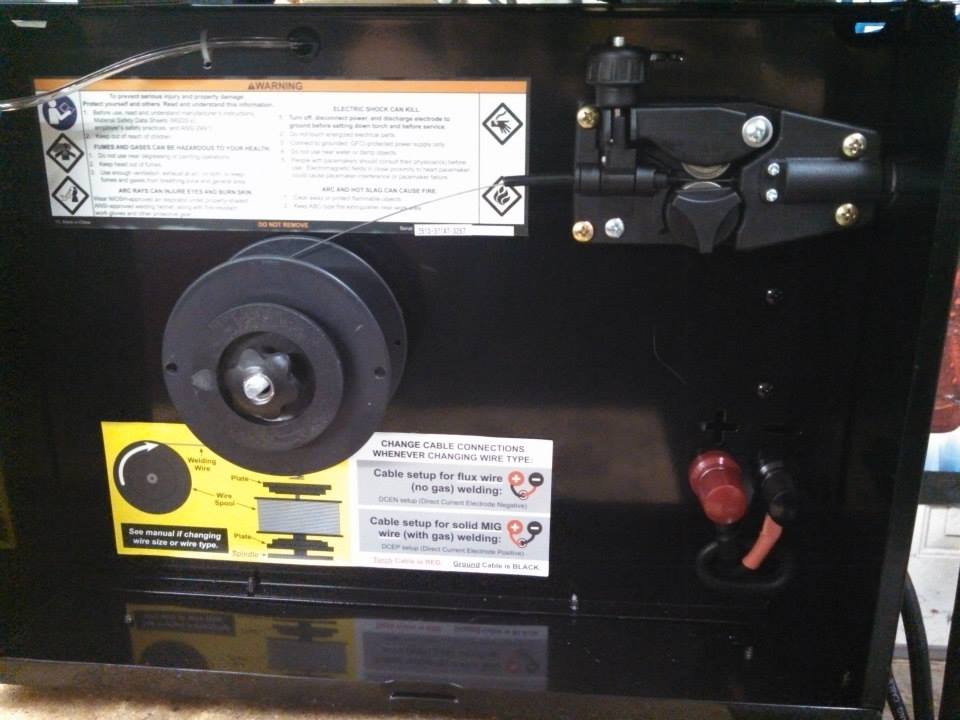

The front of the welder has 4 heat settings, similar to the dial on other welders, ABCD this just uses switches instead of the expensive rotary switch, I may upgrade this, but being that I can use these switches with gloves on easy I may keep them.

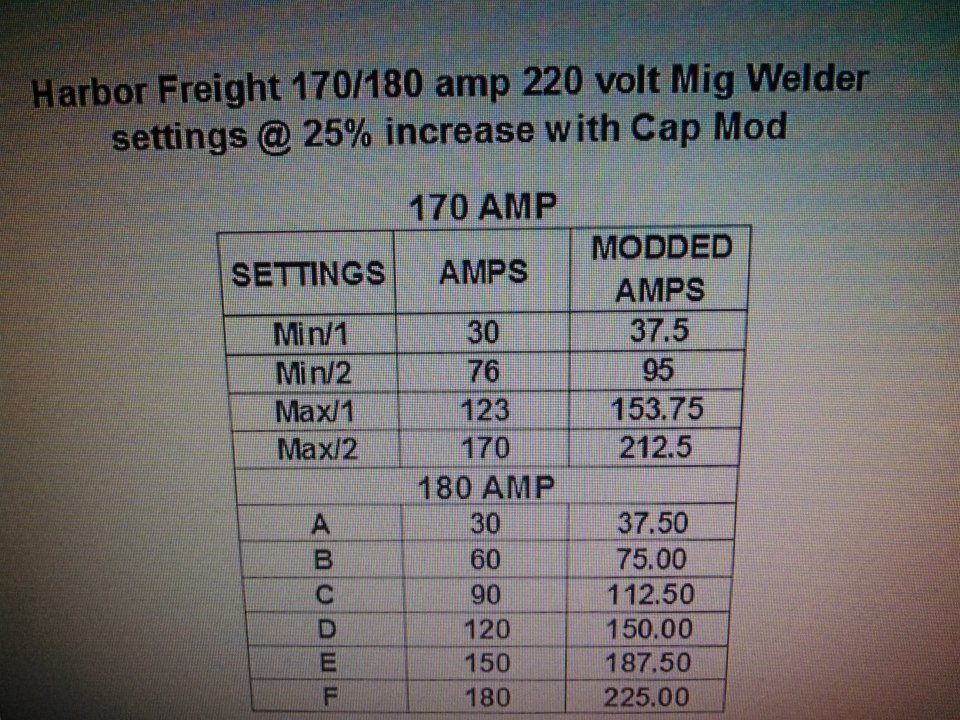

The values. Comments

The next few pics you can see where i welded a 1″ chunk to the 2″ chunk! ( I am no pro welder ) but it was very solid.

So here is where it gets amazing, the weld on the left is WITH the caps and the one on the right is WITHOUT the caps.

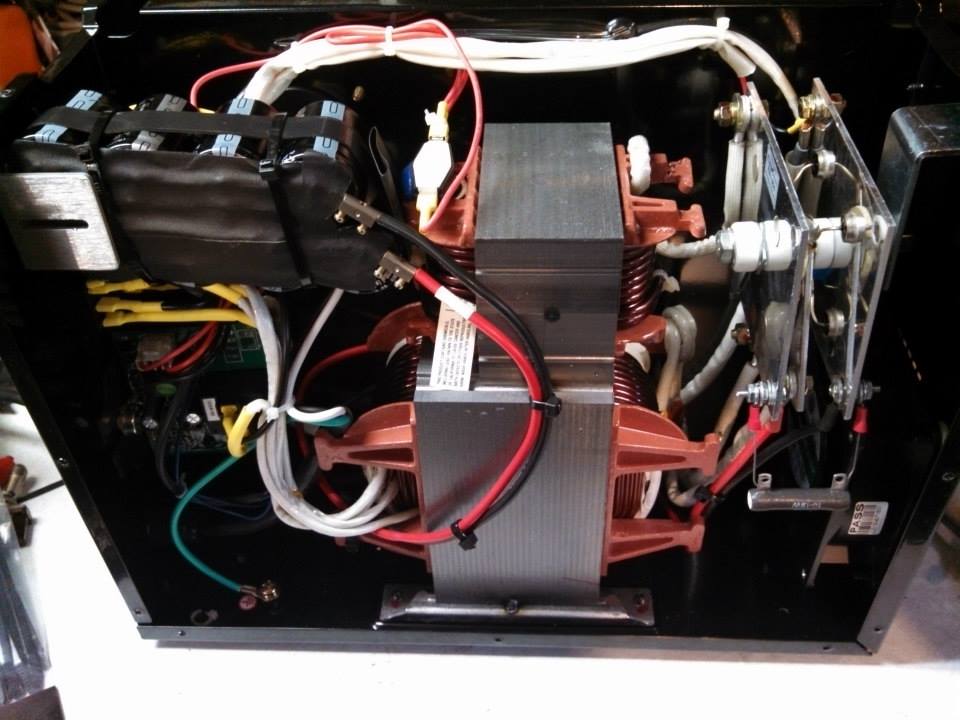

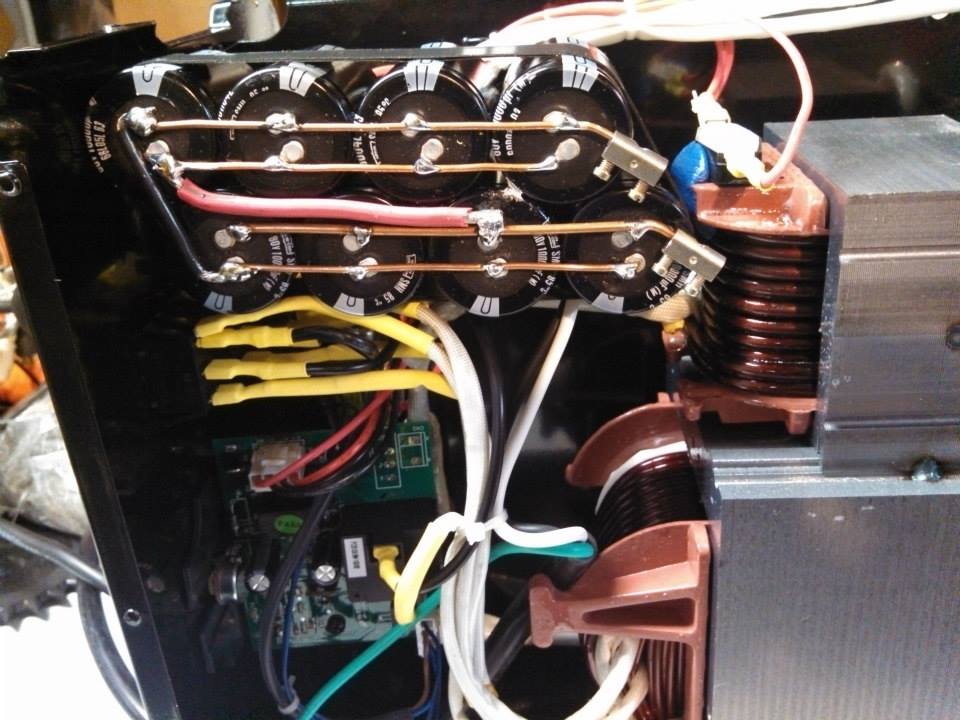

Here is the inside of the welder. ( Yes I bought a brand new welder and tore into it haha ) Comments

Here are all the caps pulled and ready to install. Comments

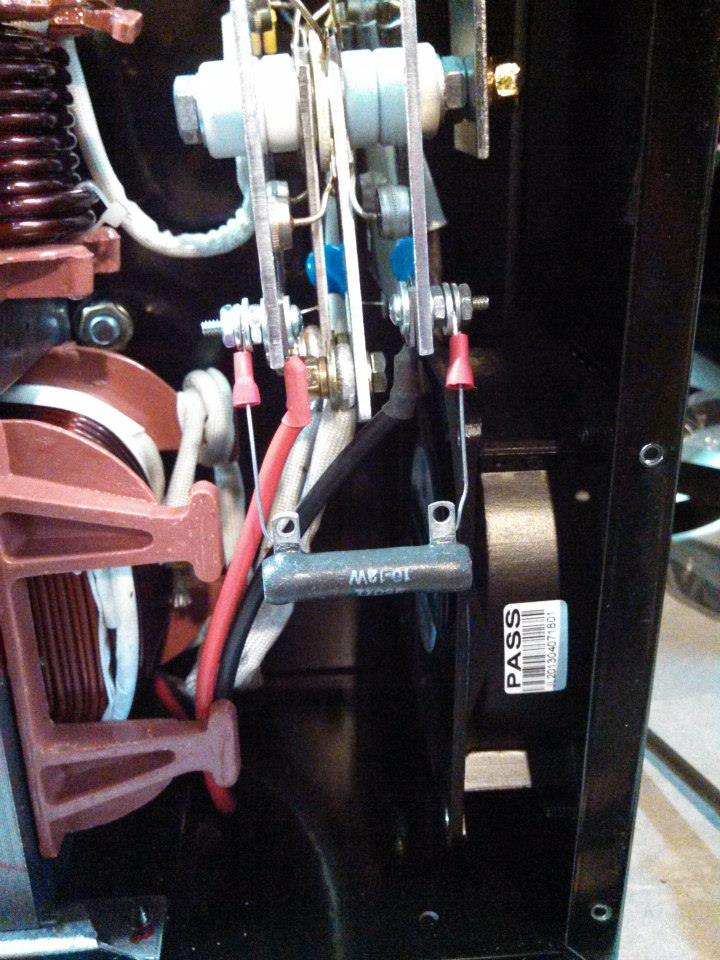

Here is my 250Ohm bleed resistor to draw down the cap bank, it is 12Watt ratted and take about 50 Sec to bleed down the caps. Comments

Another angle of the same 2 welds.

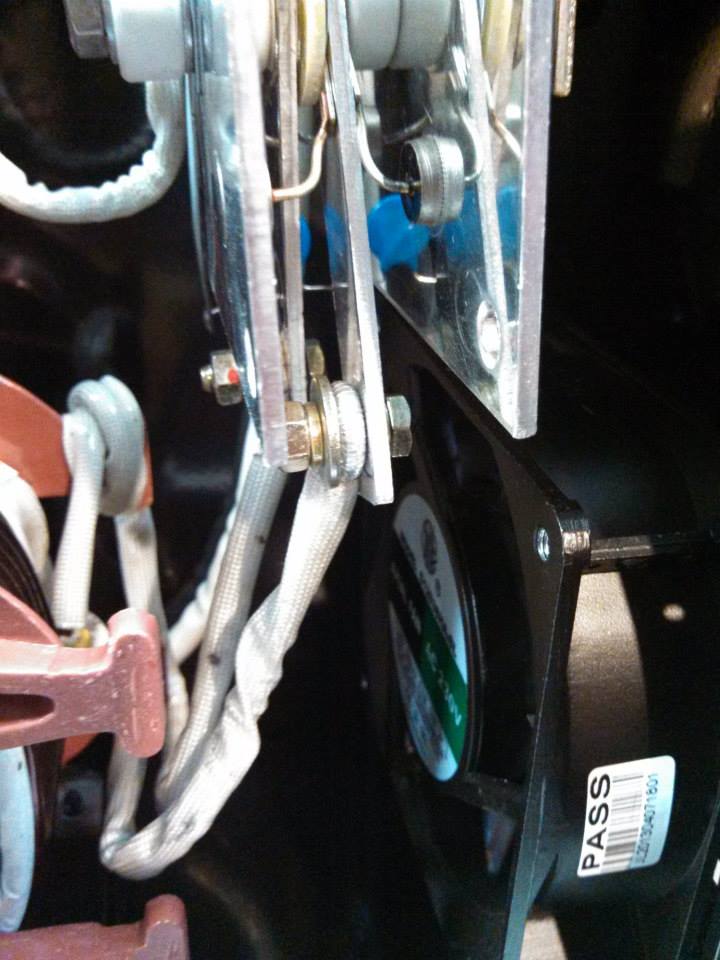

The strain relief is a bit weird. This will also be replaced. Comments

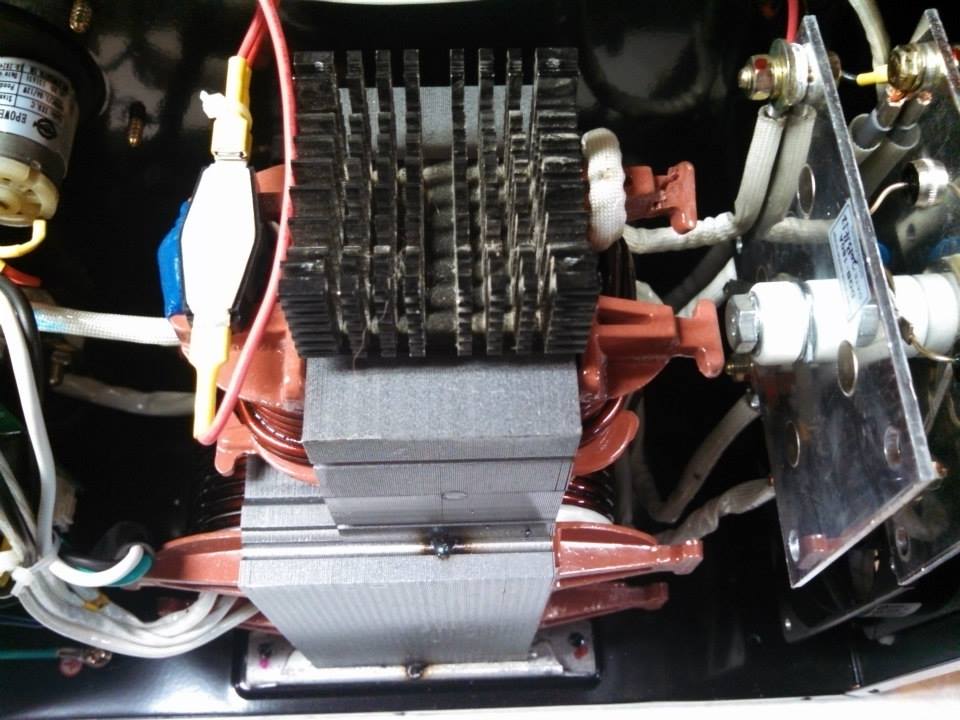

The rectifier is made by a name brand MFG and has a 180 amp ratting. Comments

Here is the completed cap bank it is 80,000MFD 80V ratted. Comments

The gun I was surprised at the quality it uses Lincoln parts ( or at least interchangeable with Lincoln.) The only down fall is the gas valve is in the gun and not a solenoidal in the welder, BUT I found this to work pretty cool, if I slightly press the trigger just gas comes out and no wire or power, so at the end of a weld I can hold the gun with just the gas going to keep things happy.

And all wired up and ready for service. Comments

Good penetration.

The fan is also name brand and has very good flow rate. Comments

The ground clamp.. Ehh it is a harbor freight / china piece. That will get replaced ASAP with a good one I have on my old welder. Comments

Here is the inside of the spool holder, the spool tension is nice and adjustable, the feed rollers are easy to remove and are dual grooved for different size wire. The lower right are massive binding posts for changing polarity.

And here is where it gets amazing, this is a 2″ thick chunk of solid steel!

The side nothing fancy, but the spool access has a nice latch, and the metal is a nice thick gauge

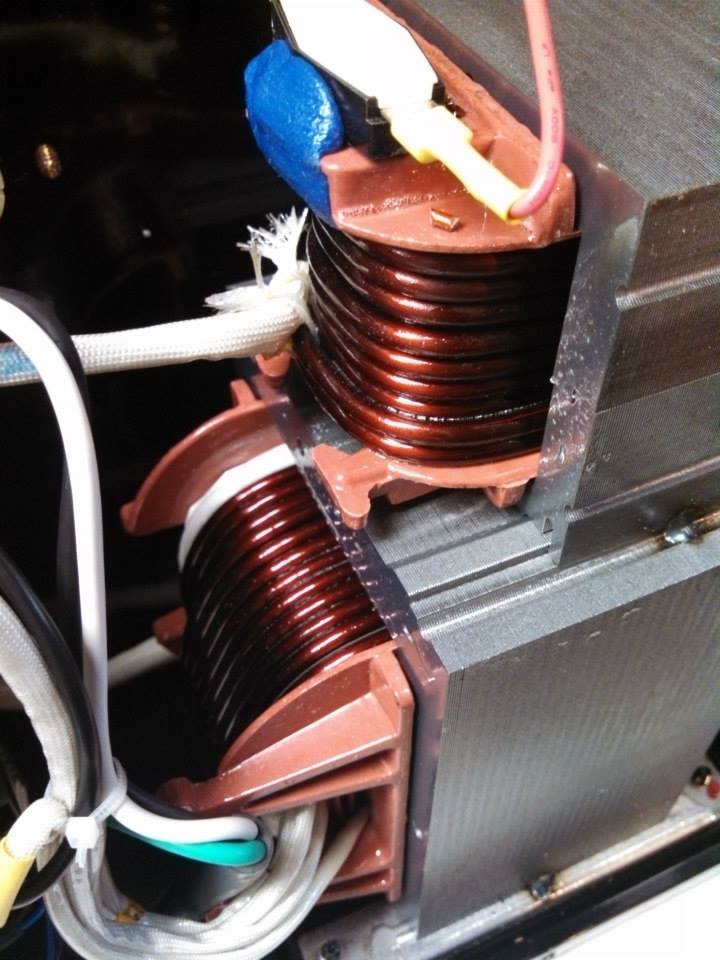

Main transformer and stabilizing reactor on top. with thermal switch on top of that. Comments

Much better quality then HF would provide with their welders. nice heat shrunk connections. Comments

This welder is only ratted for 1/4″ the chunk above is a solid 1″ steel block!

Quiz time, one of these welds was done by my welder the other done with a Lincoln WeldPak 175 HD… What one is what? This was on 1/4″

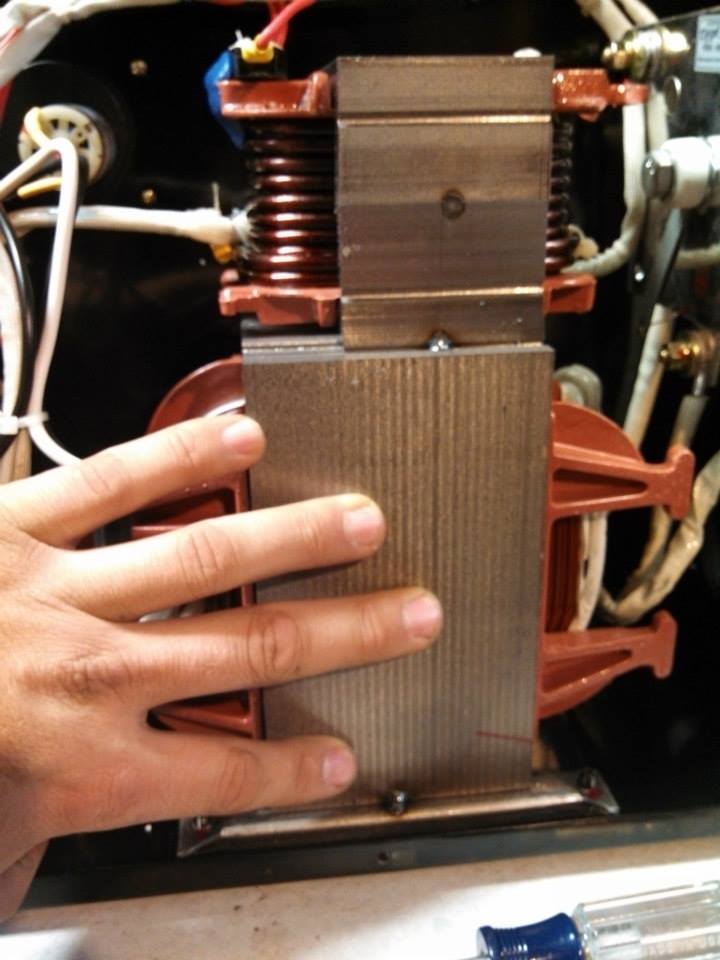

Test fitting a heat sink to help keep the reactor cool. Comments

Test fitting it into the welder. Comments

Sealed and ready to install. Comments

Here is the change in capacity with the cap bank installed. I will be adding a switch to turn the cap bank on and off this will give me , 8 heat settings!

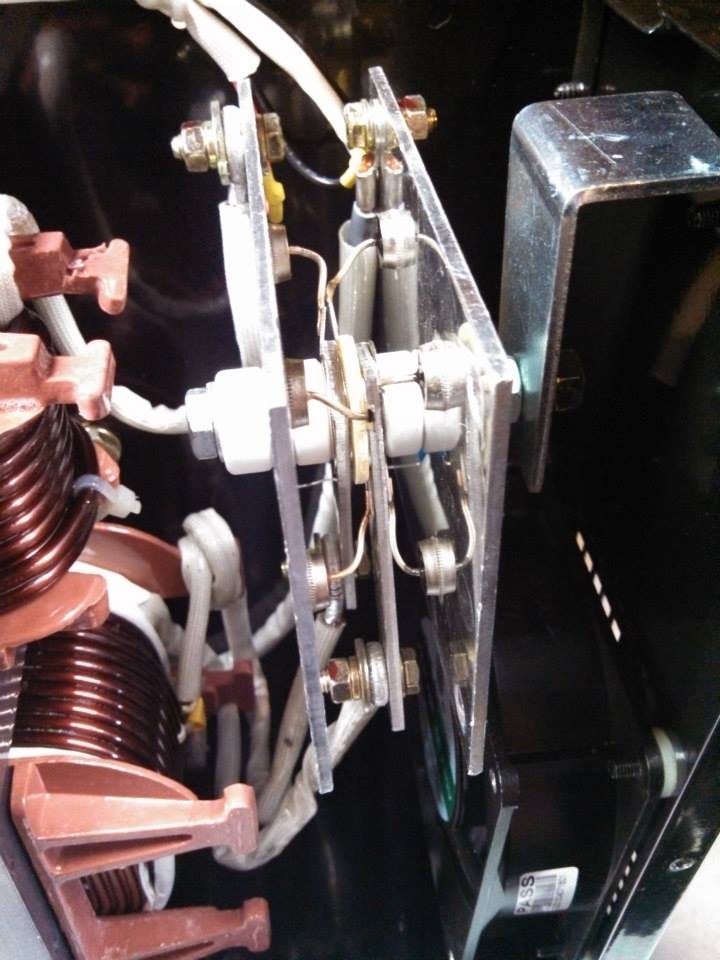

I needed caps for my welder, All high end welders have a capacitor on the rectifier, this smooths the ripple on the DC before it goes through the reactor. Most welders use a 50-70,000 MFD Cap ratted for 60V. In this pic you will see a massive blue cap this is only 30K MFD and is huge and would never fit, so I found some very high quality inverter caps that are 10K MFD each.

This is the welder fresh out of the box at power 4 or MAX with flux core. On a 1/4″ steel plate.

I then pulled as many as would fit into the welder from the boards.

You can see it has no problem heating it up.