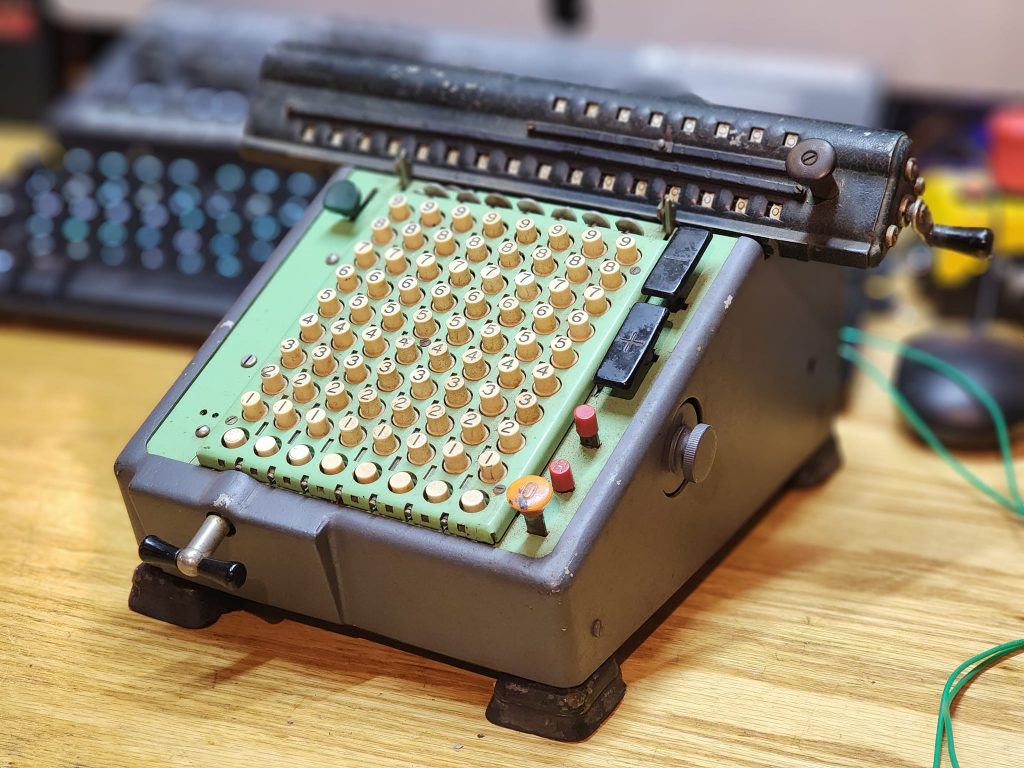

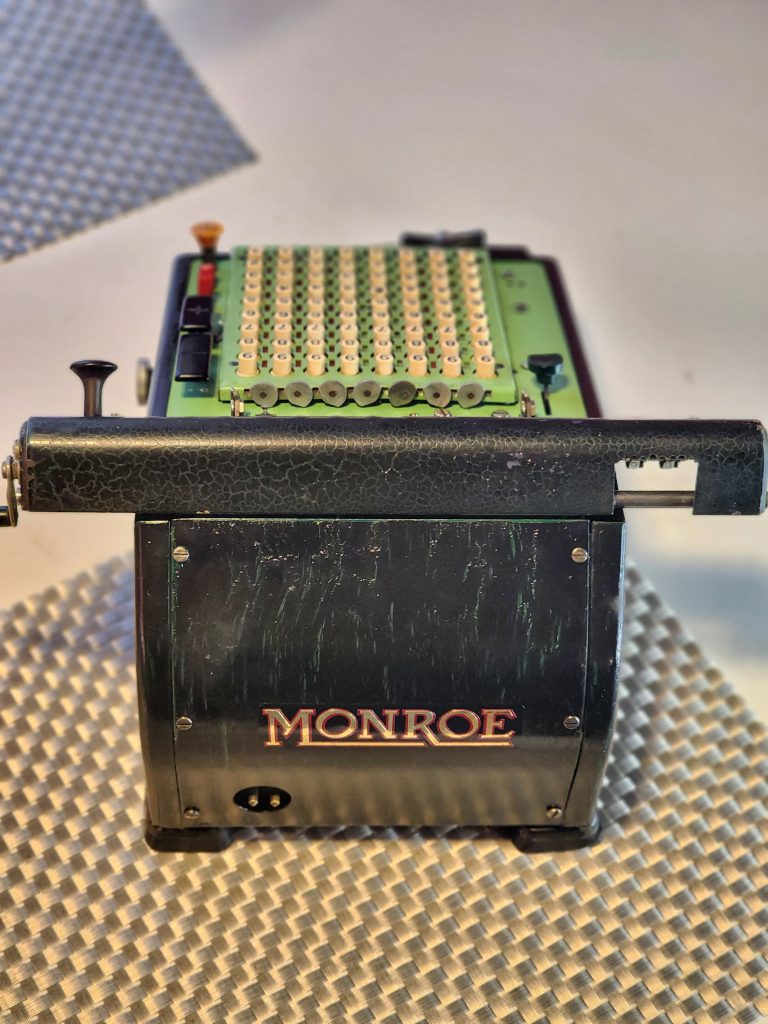

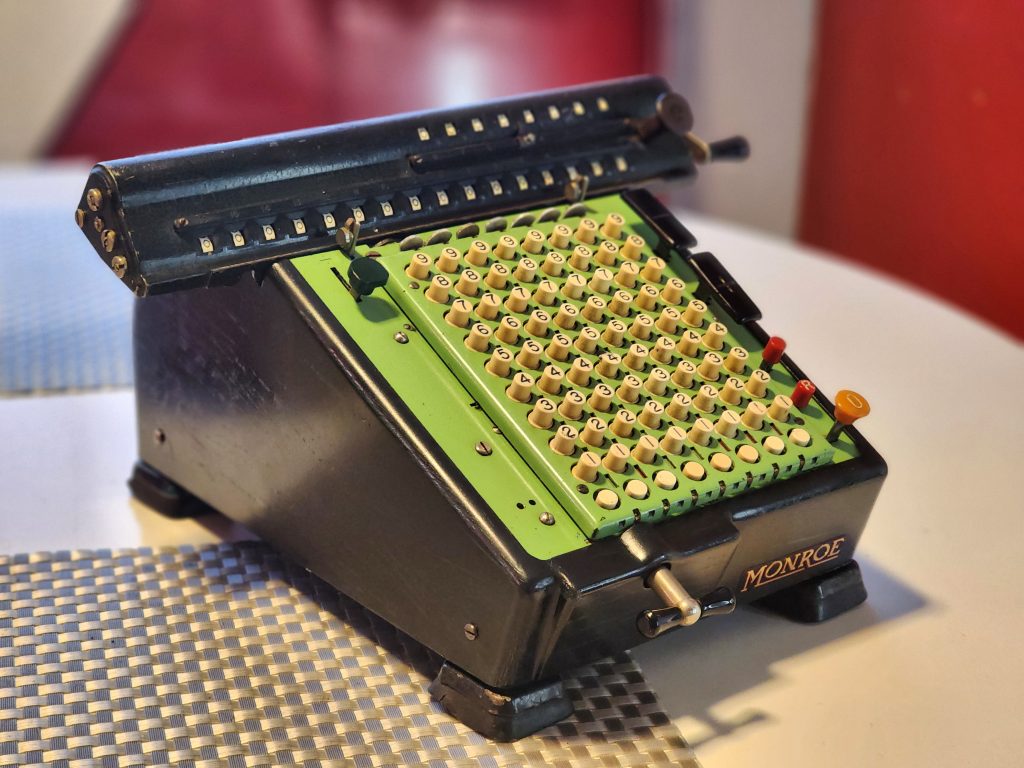

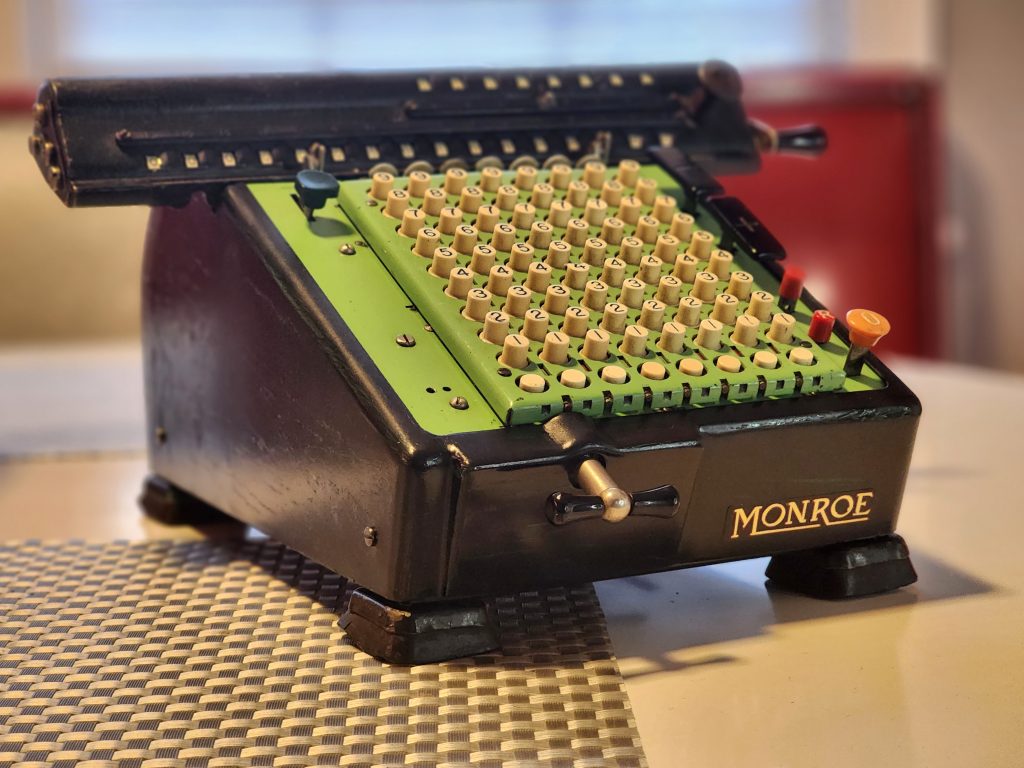

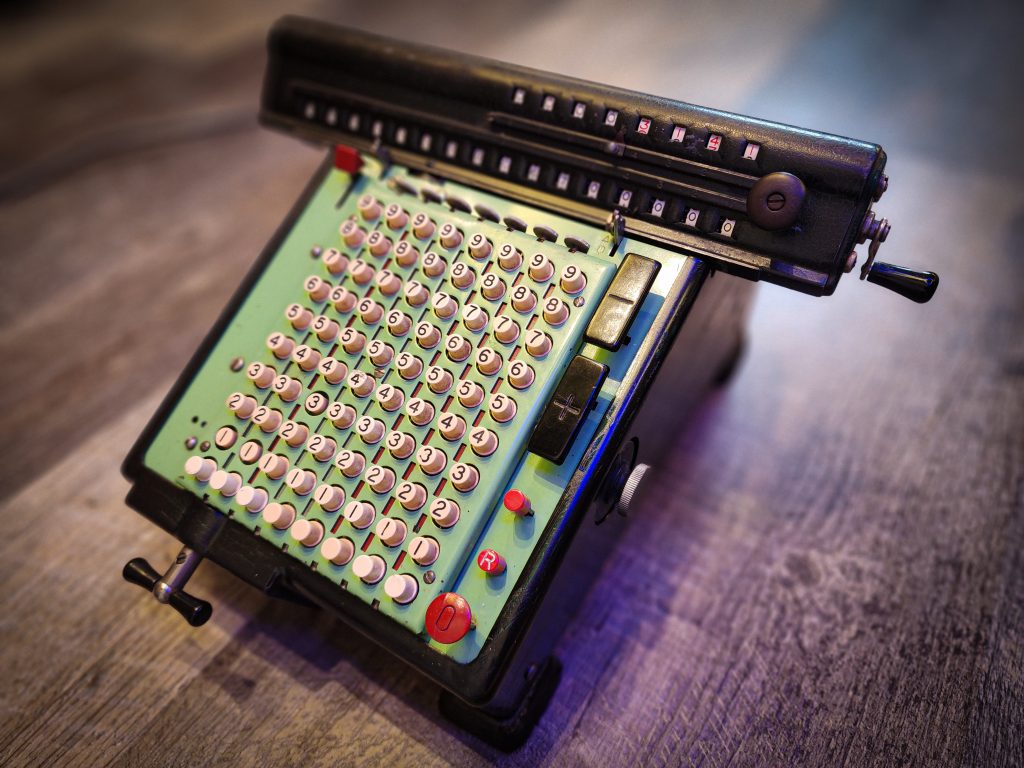

I recently picked up this broken Monroe LA5-160 Calculator for the collection, it was cheap for it had no power cord and was not working ( jammed up )

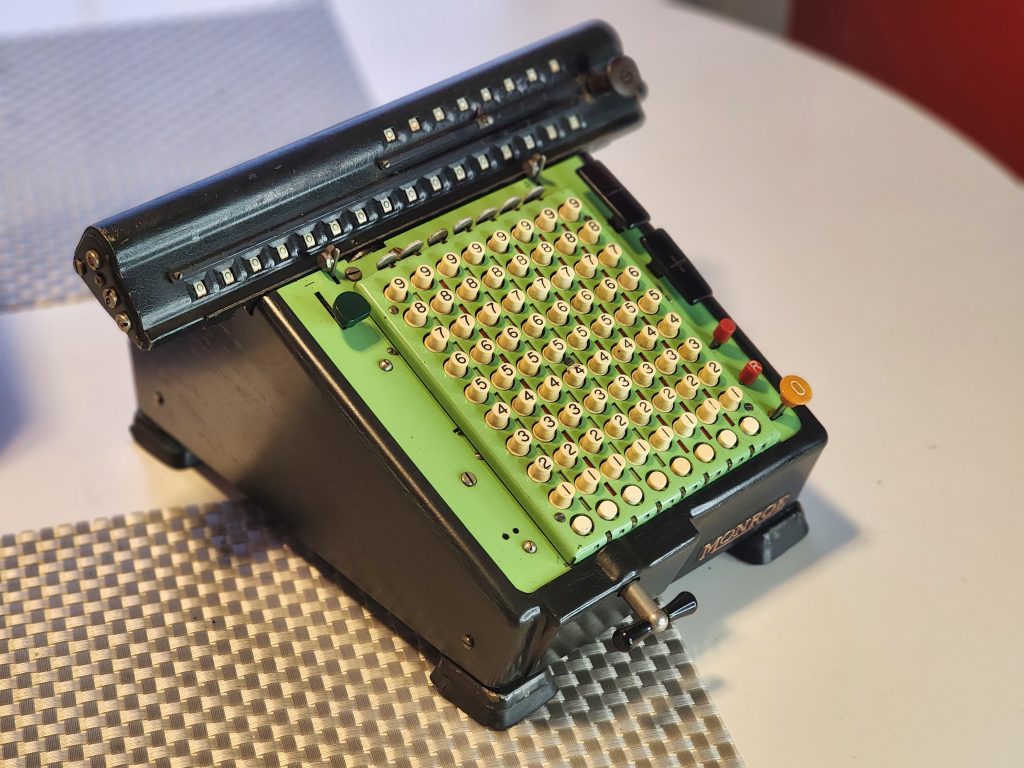

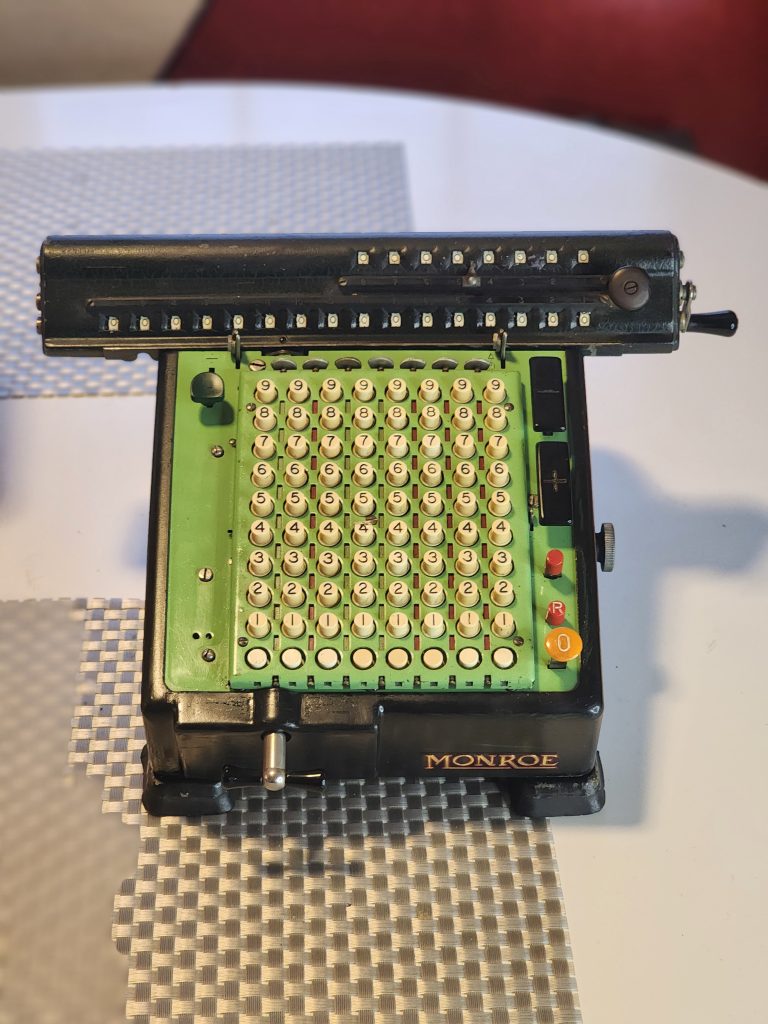

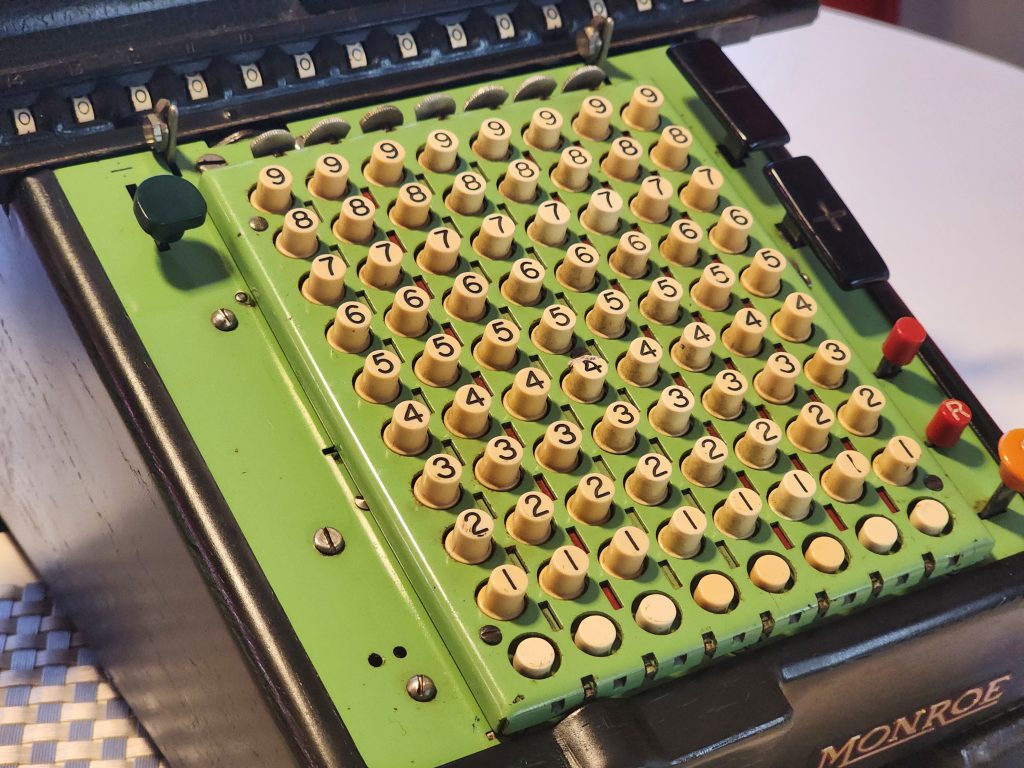

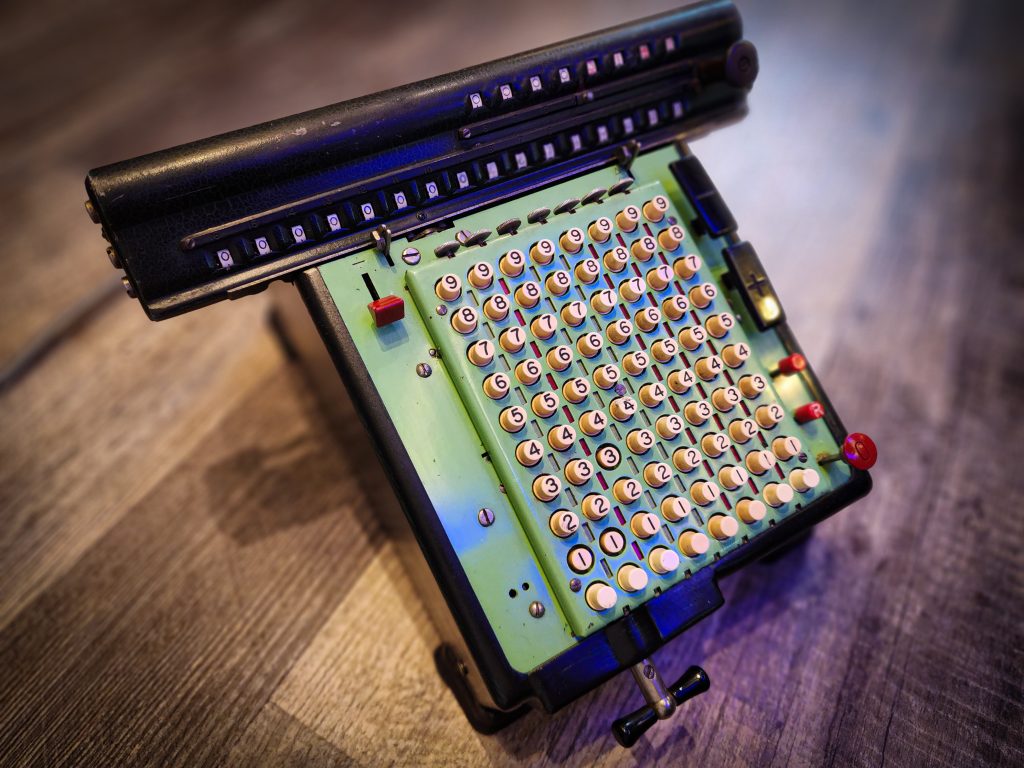

Here is a walkthrough of it when I first started testing it for operation.

Here I am doing an approximation of Pi semi automatically. to make sure that other parts where working as they should.

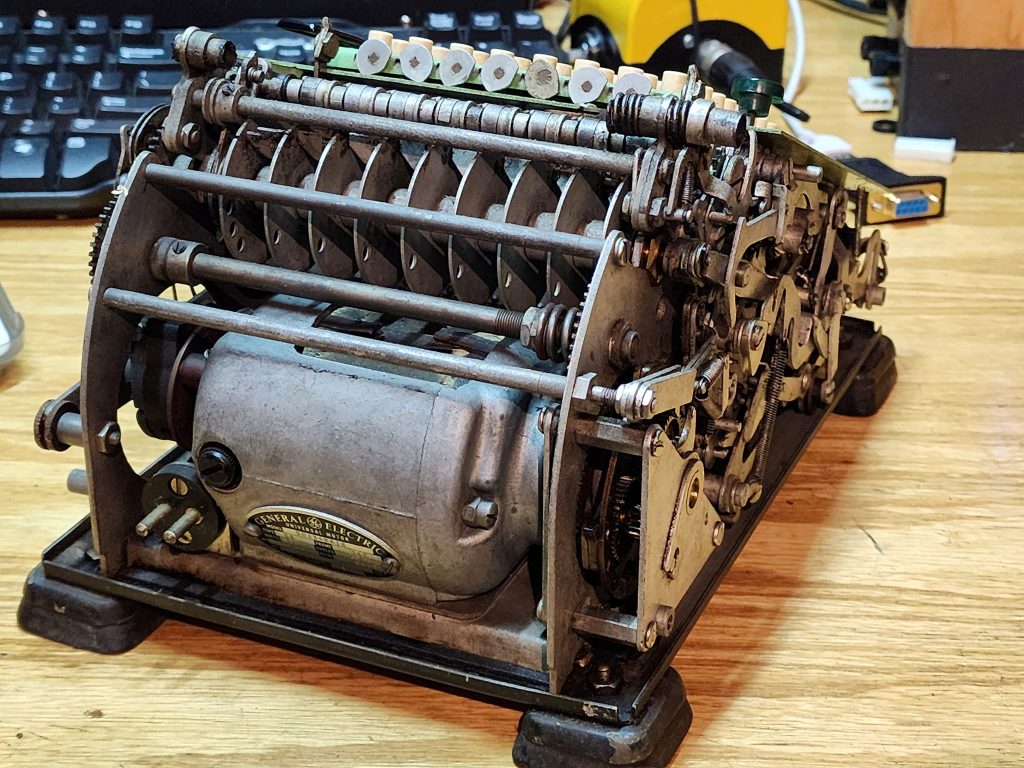

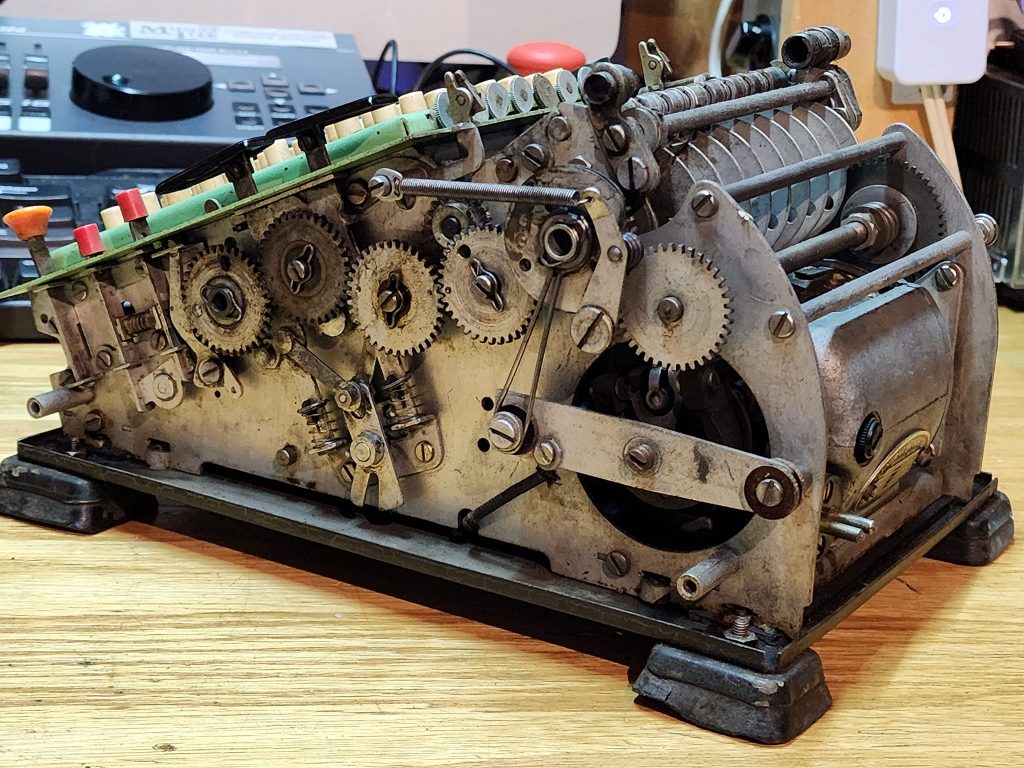

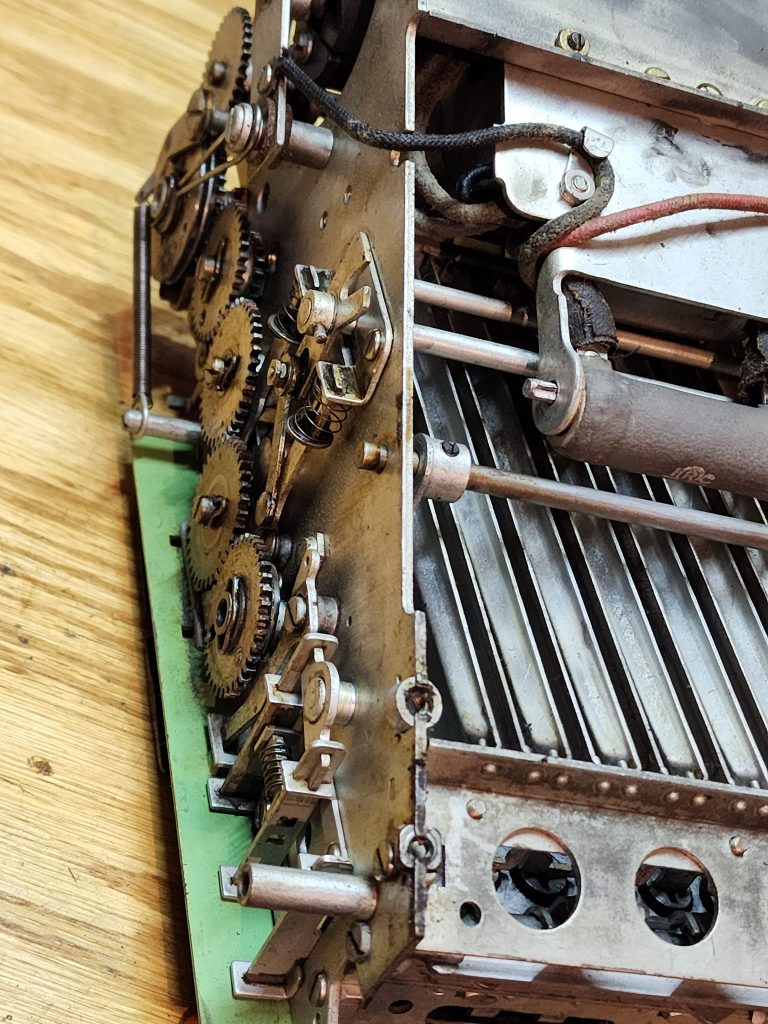

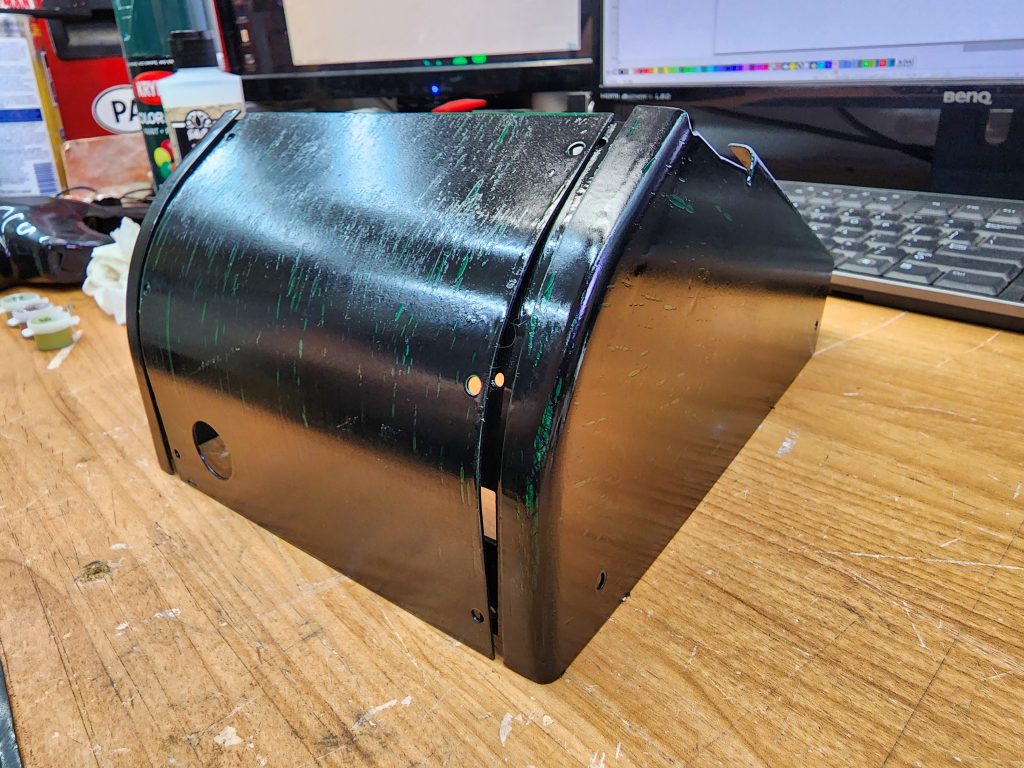

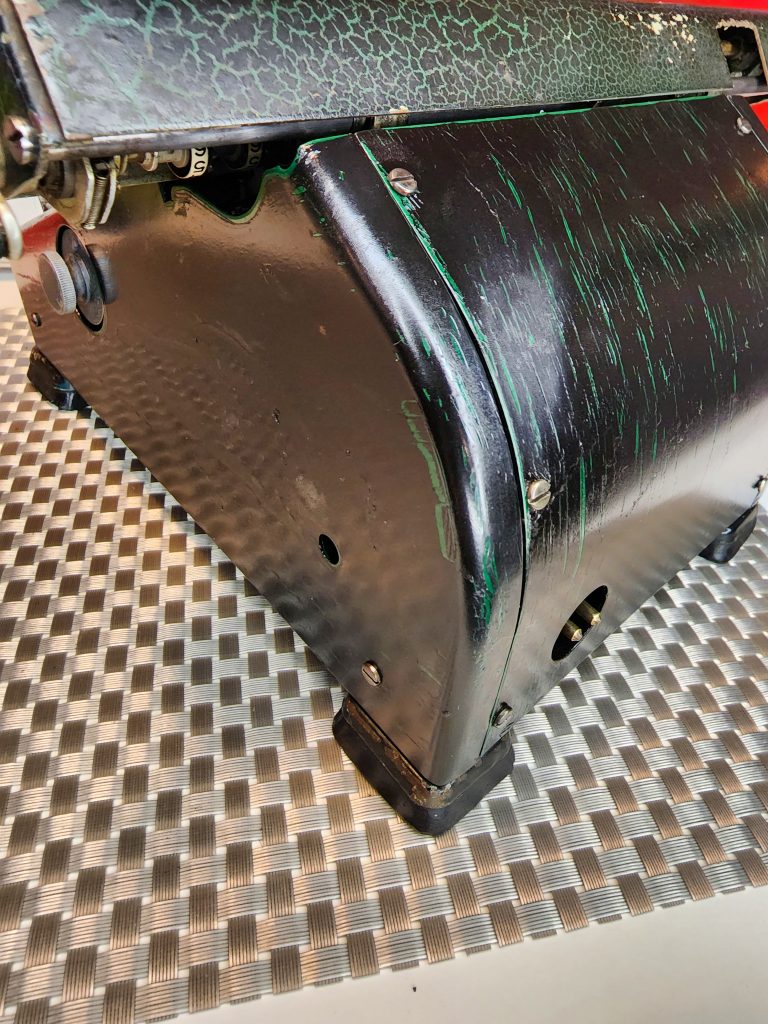

Next, I tore into it, to clean it up and lubricate all the many moving parts, and had to take the main carriage bar out and clean and polish it, plus bend it back to straight.

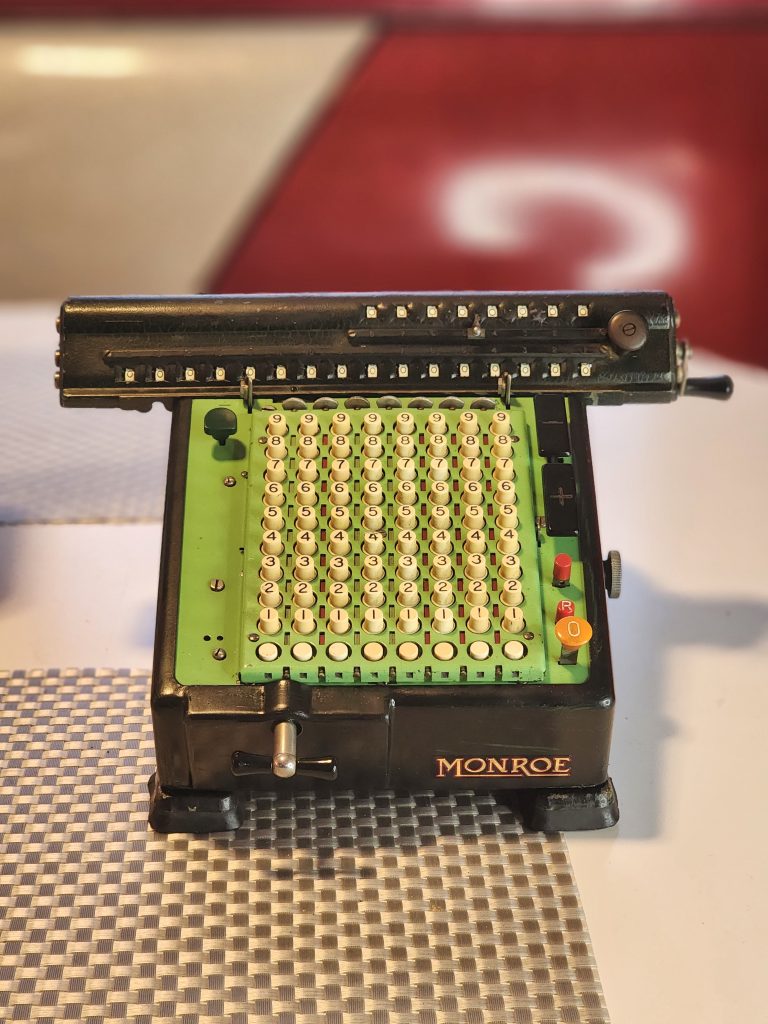

Now that it is all cleaned up, I put it back together to make sure all the parts work, and it works great!

Here is a video of me walking through all the features!

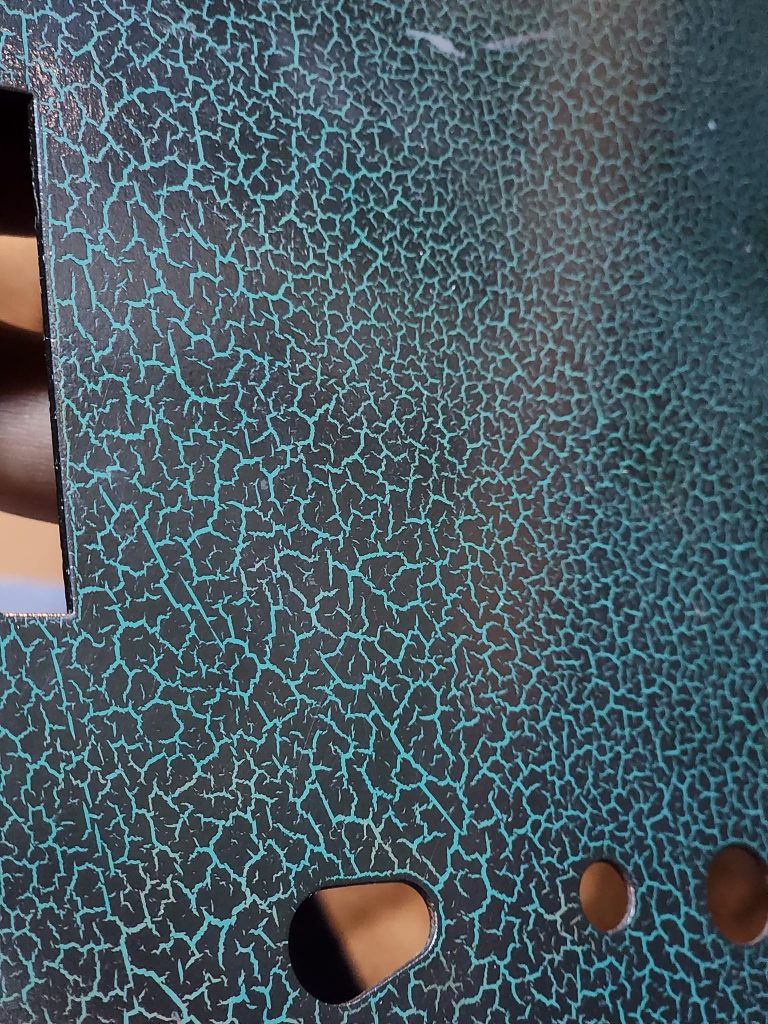

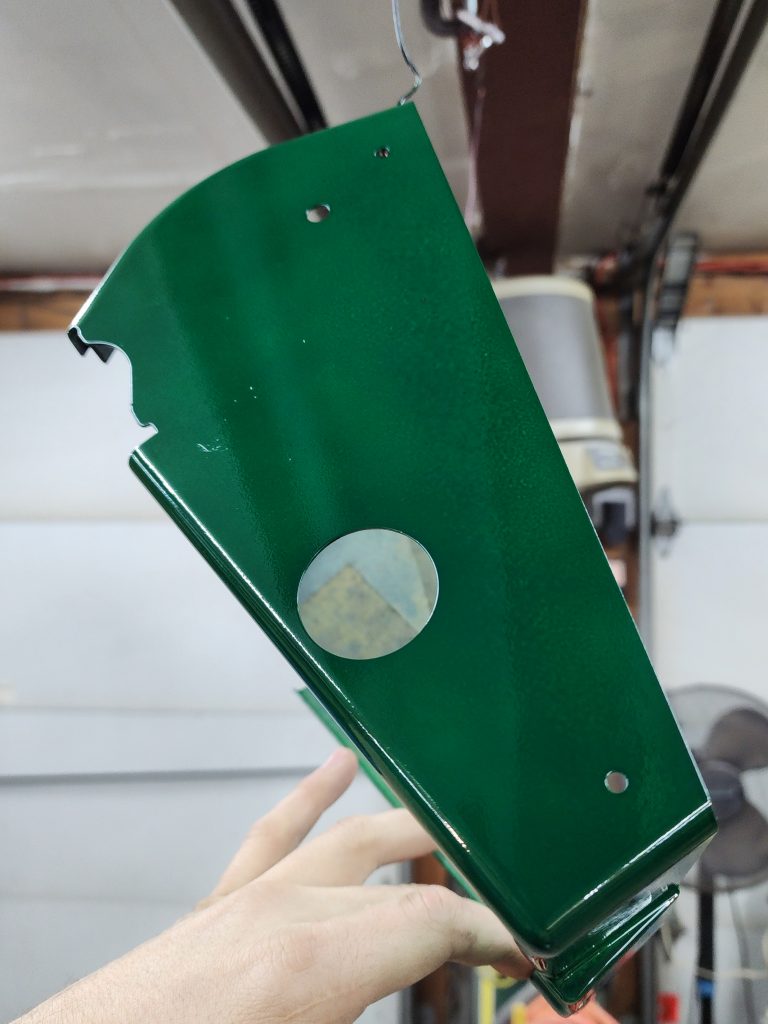

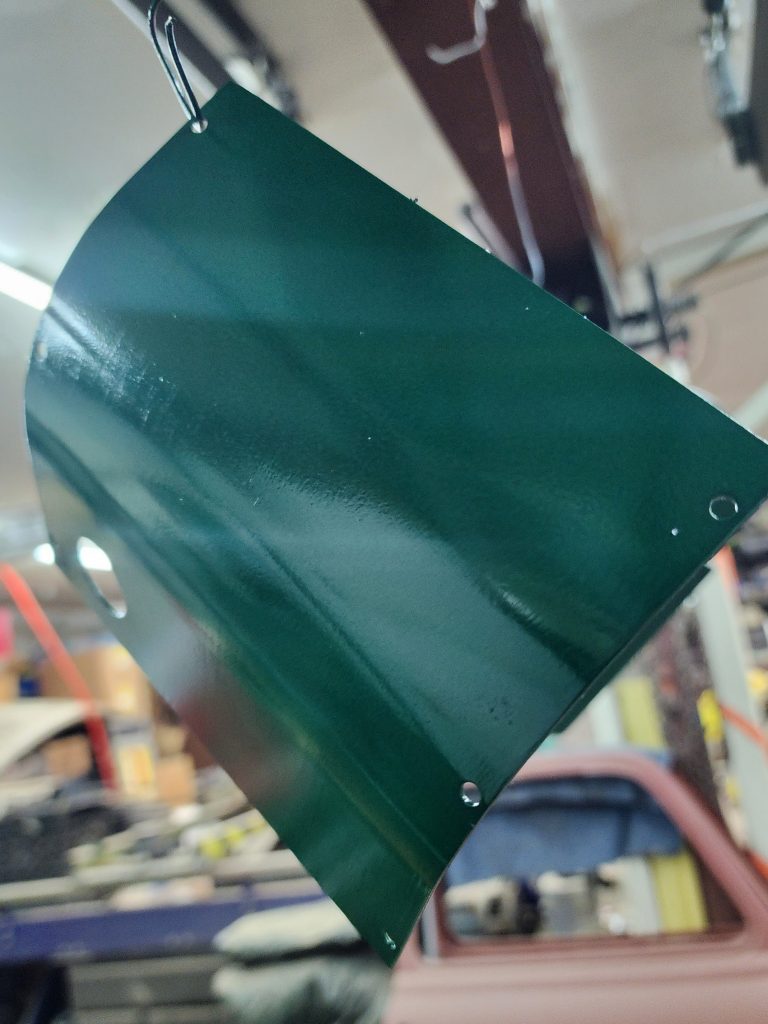

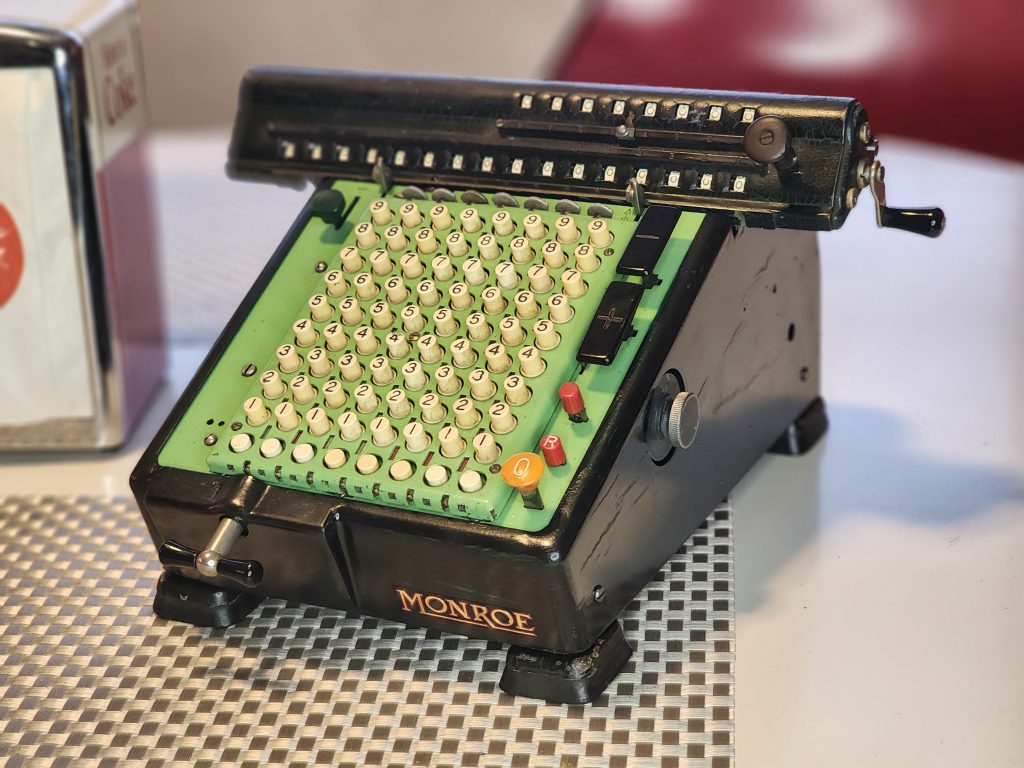

The next step in the project is to go buy some crackle style paint, and try and repaint the tins and have them match the old original parts.

For example here is what it should look like, and with all original buttons and paint.

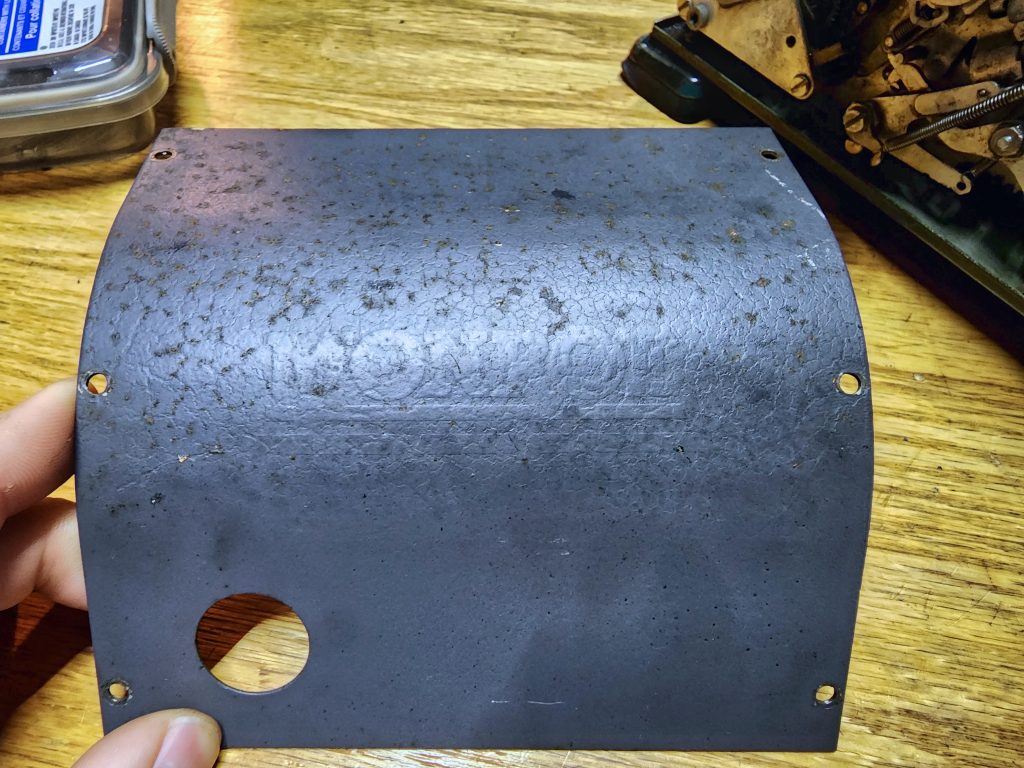

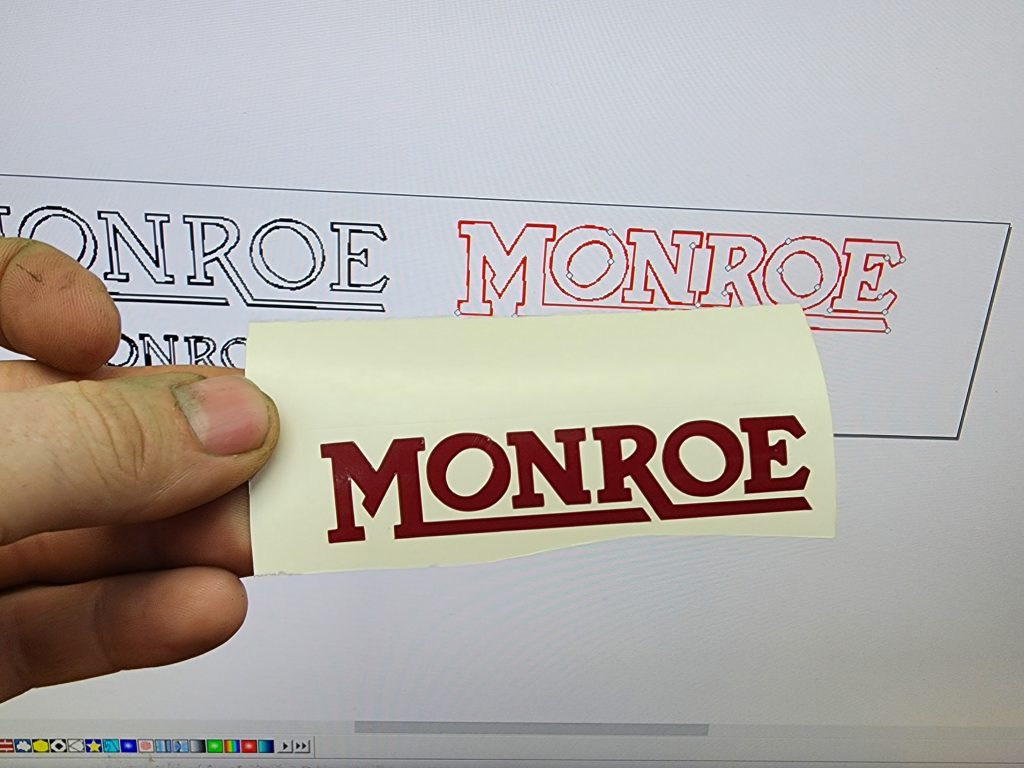

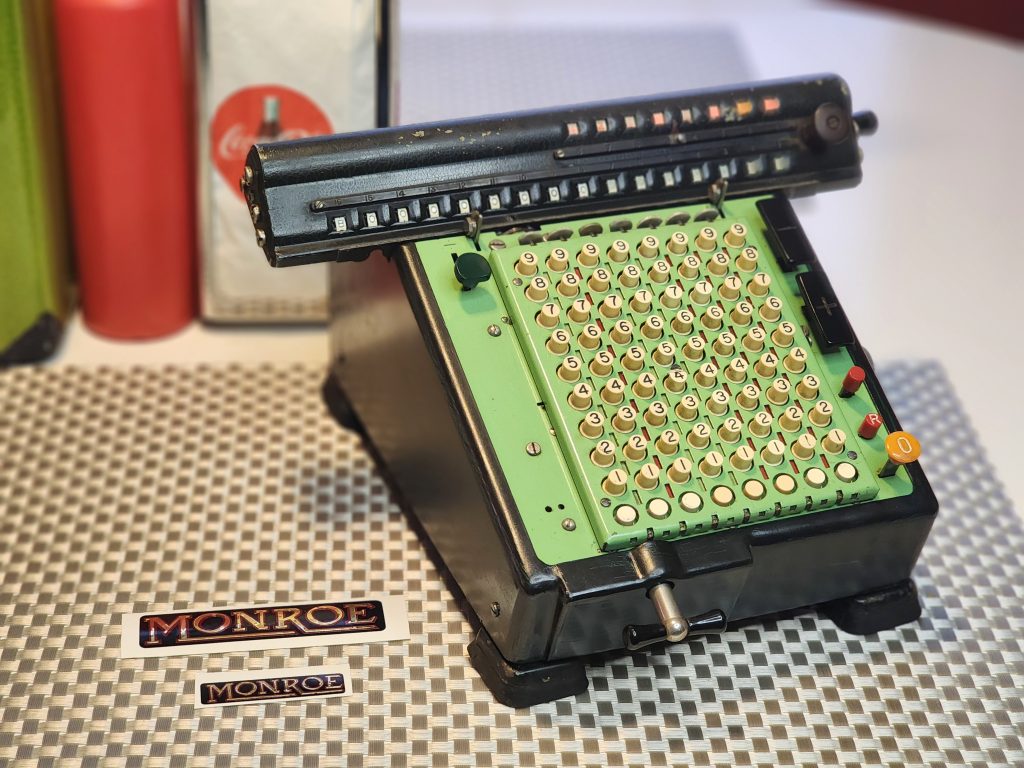

I started the process of sand blasting the old chassis and doing my first ever crackle paint finish, Matching the colors of the original was a fun project. I was able to measure the size and shape of the old logo through the gray paint job that was blasted over the top of the original paint and finish.

Recreating the original logo was quite the process,

I may end up stripping and trying the base finish again some day soon, but for now it looks so much better than the gray paint that did not belong on there when I got it!

UPDATE: 2/10/2023

I looked all over the internet to find images of what the missing buttons looked like, I fired up Fusion 360 and hand modeled replacement button of the correct size and shape. I explain more here:

Here is what the model of the ‘0’ button looked like.

Here are some photos of the 3D printed buttons, and final shots of the calculator.

I have two LA5’s. One won’t stop running and the other won’t start. If you fix one for me you can have the other. Do you have a repair service for these?

John,

Thanks for the comment! My LA5 was my first time working on one of these! I am no expert when it comes to these. I do appreciate your confidence in me though on this! A few pointers I could direct your way, is to remove the cover like I shown above, and try and get the carriage to move as free as possible. A light oil or even 3 in 1 oil, helped get mine moving well again.( Lot of manual assisting with my hands to get it moving better ) The old oil will tack up and cause parts to not fall free, so it can not complete the carry so gets hung. If you follow the wires you will see a small switch off to the side of the motor, you can clean these contacts with some fine grit sandpaper between the contacts this may get the non working one spinning again! ( Like cleaning points on an old ignition system. )

I wish you the best on your project! Sadly I do not ( At present ) offer a repair service for items like this.

I bought a Monroe LA5-160 some time ago and i have been refurbishing the machine. It hadn’t probably been used after 1970’s, so everything was a bit jammed. Cleaning of old grease and some new lubrication helped. First the subtraction began to work and then also addition after some use of the machine. To get the automatic division to work was quite a job. After quite much cleaning and lubrication it works quite well. The issue there was to get the automatic turning of the handle of the carriage to work precisely. At the beginning the mechanics couldn’t move the carriage handle properly and the division was every time stuck at some point.

Thanks for your comment, and contact ( Emailed you back! ) I had the exact same problem with mine, turns out I discovered the carriage move on divide, is carried out with mostly inertia, there is a ‘foot’ that kicks the carriage advance, and the mass of the carriage is meant to keep it going sideways and to fall down into place, if the slide is a bit gummy or the lift and lower, it will kick up, but wont slide all the way or drop down, and than jam up. This was a very frustrating problem. I had to lube the slide and pivots and work the knob by hand many, many, times by hand to work it completely free so I could just smack the handle and it would flip over to the next place slot. Than Auto divide worked great!

Thanks for sharing your story! And glad you are saving another LA5 in this world!

I acquired an LA5-160 recently for $10. Decent condition. Came with a crunchy power cord, but I may be able to salvage the Belden round plug off the end. I am missing the three lower right red buttons: Clear repeat, repeat and the big zero button. I saw the YouTube video where you worked up replacement buttons in Fusion 360, but I don’t see the 3D models anywhere. Please point me to your models.

John,

What a great price! And Good catch, I totaly forgot to post my models! Here is a direct link to the STL files for the two keys I modeled.

https://www.djdlabs.com/MONROE_KEYS.zip

Any questions let me know!

Best of luck with your project!

Hi my name is Cristian from italy.

Which is the voltage of power supply? Here we have 230 Vac

Hi Cristian!

My model was 110V 60Hz but can also run on 110V DC. Depending where yours was built may have a different motor inside.

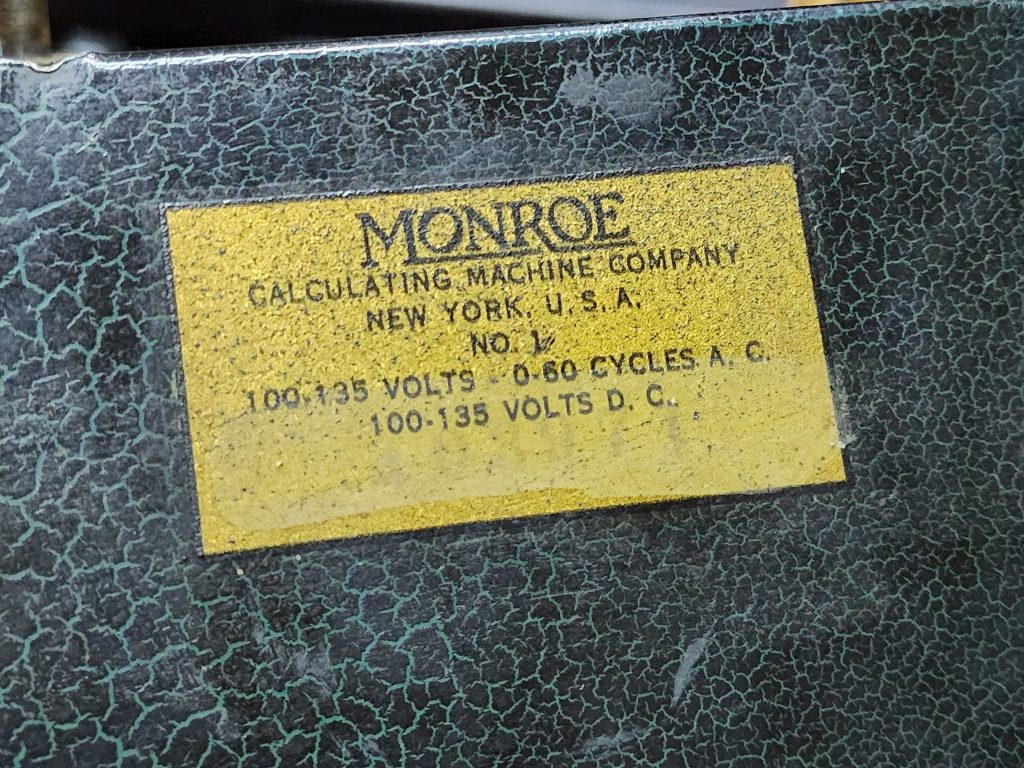

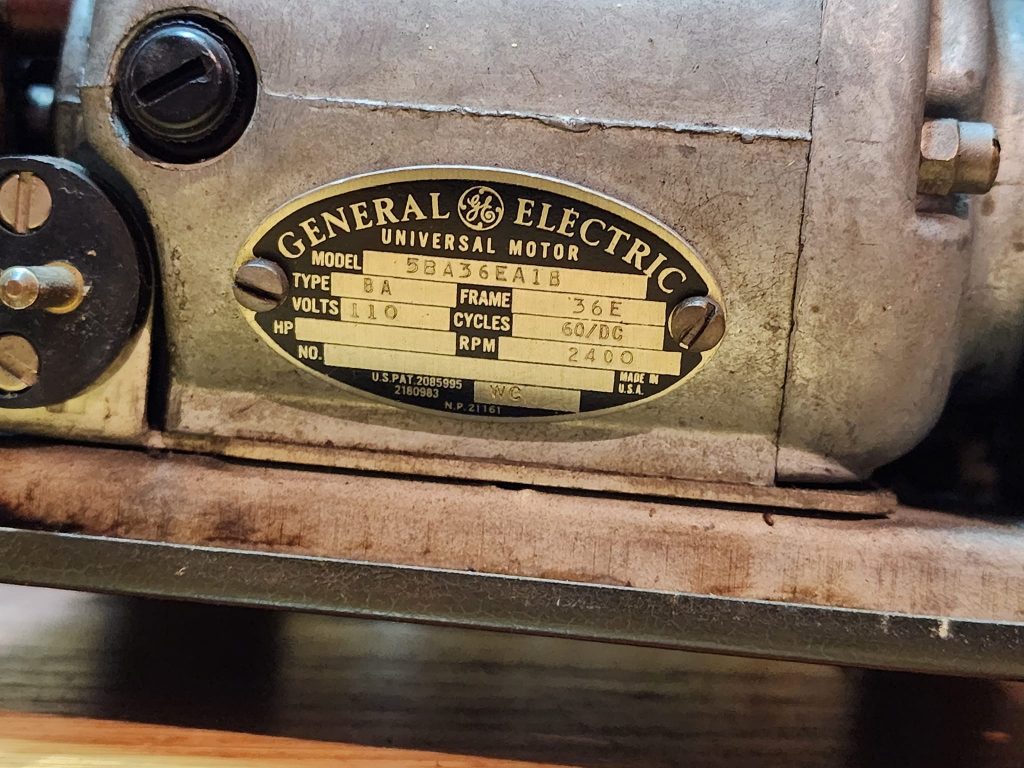

Here is a picture of the name plate on my motor that shows the power neeeded.

https://www.djdlabs.com/wp-content/uploads/2023/01/325662913_520607256725691_6561008064092069072_n.jpg

Yours should have a similar plate behind the main cover.

Here is some good news, lower voltage should not hurt it for a test, if you power it at 120V and it runs slower than in my video it is a good chance yours is 230V.

As for frequency or cycles, USA is 60Hz europe is 50Hz for modern equipment this can be a problem, but for these old motors they will still work, just be it a tad bit slower.

Hope this helps!

Hi Doug!

Thank you for all these info.. very helpful for me.

I am considering to buy ones but there is no power supply cable and of course i can’t check the motor plate ( i don’t have it in my hands yet :-))

In case i’ll write u for more info and suggestion. Cristian