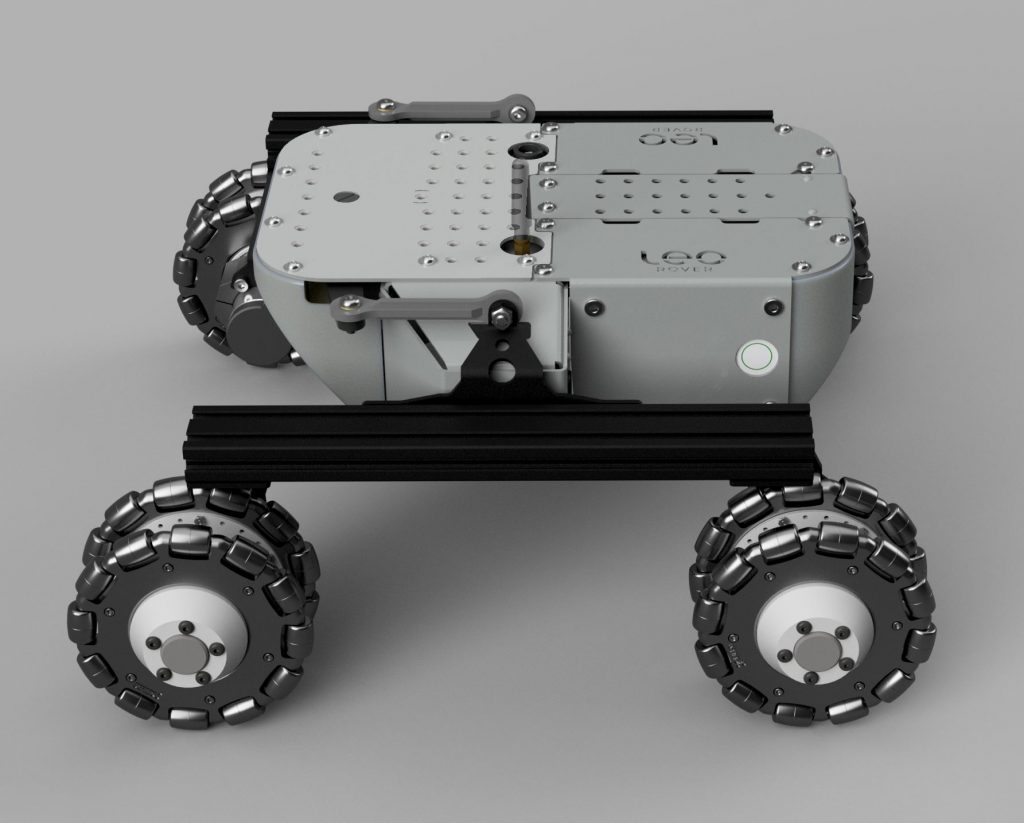

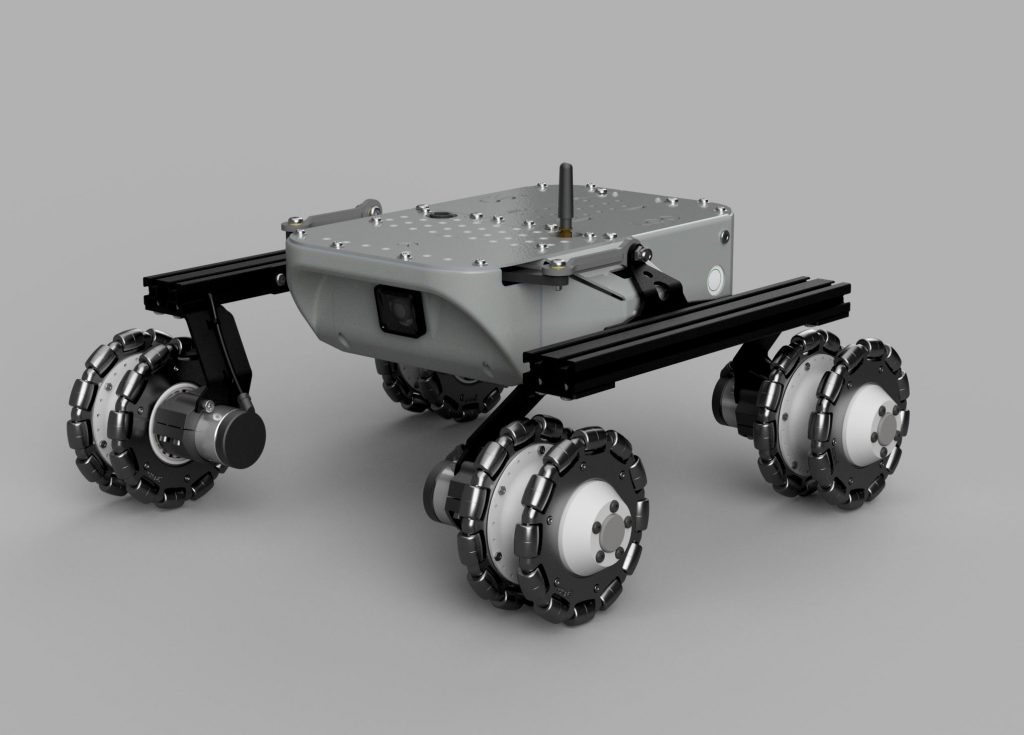

This is a prototype wheel design I am working on for the Leo Rover. The current tires work great on loose dirt and outdoor environments, but on flat hard smooth surfaces, the tires grip very tight and make for extra stress on the drivetrain and tires when attempting to ‘skid-steer’ this new design uses Omni wheels in place of the grippy rubber tires.

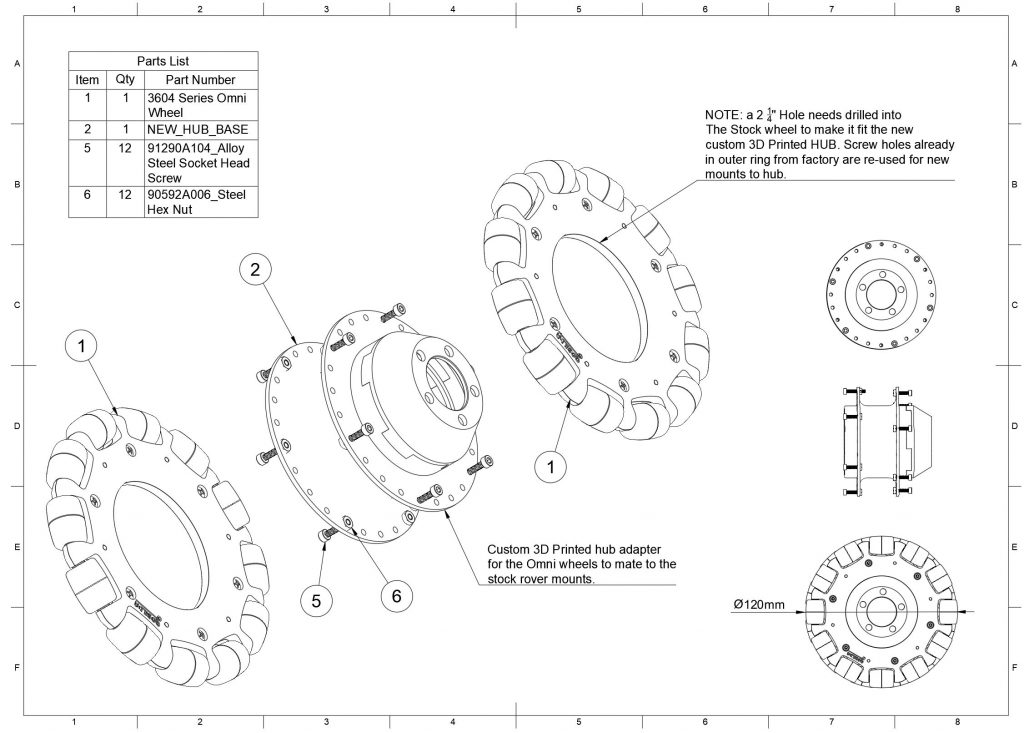

The Omni wheels are these,

https://www.servocity.com/3604-series-omni-wheel-14mm-bore-120mm-diameter/

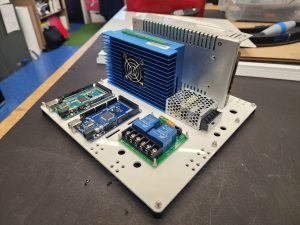

These wheels combined with a custom designed 3D printed hub:

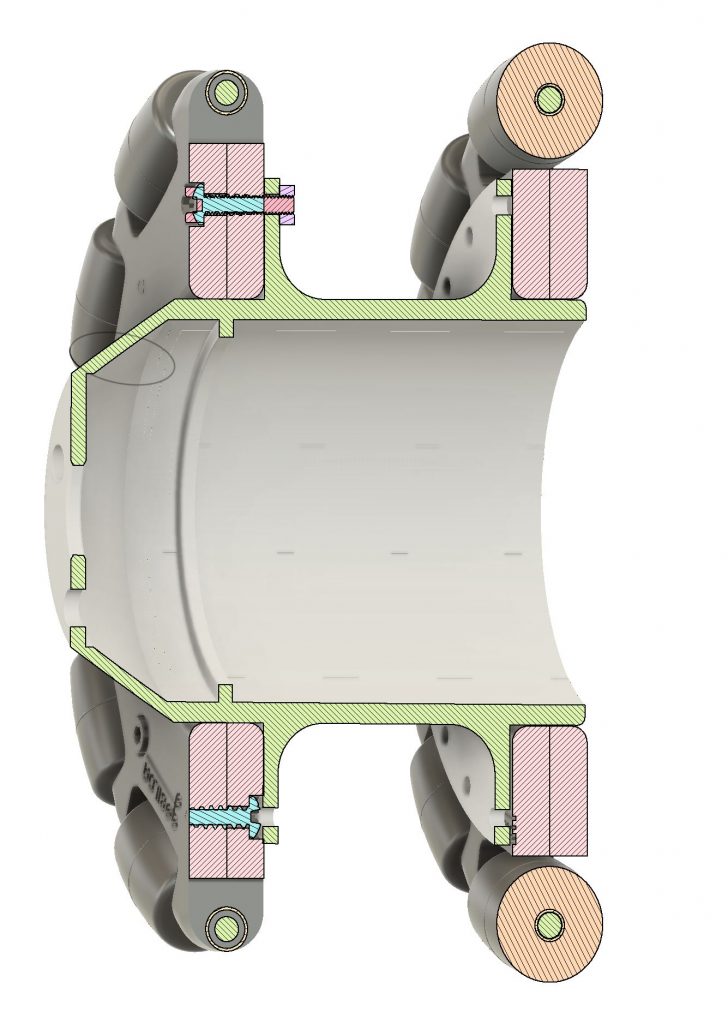

This would require drilling out a 2 1/4″ hole out of the center of the omni wheel to fit around the new hub. It would mount to the new hub with a flange and bolts, that use the existing bolt holes in the outer ring of the Omni wheel.

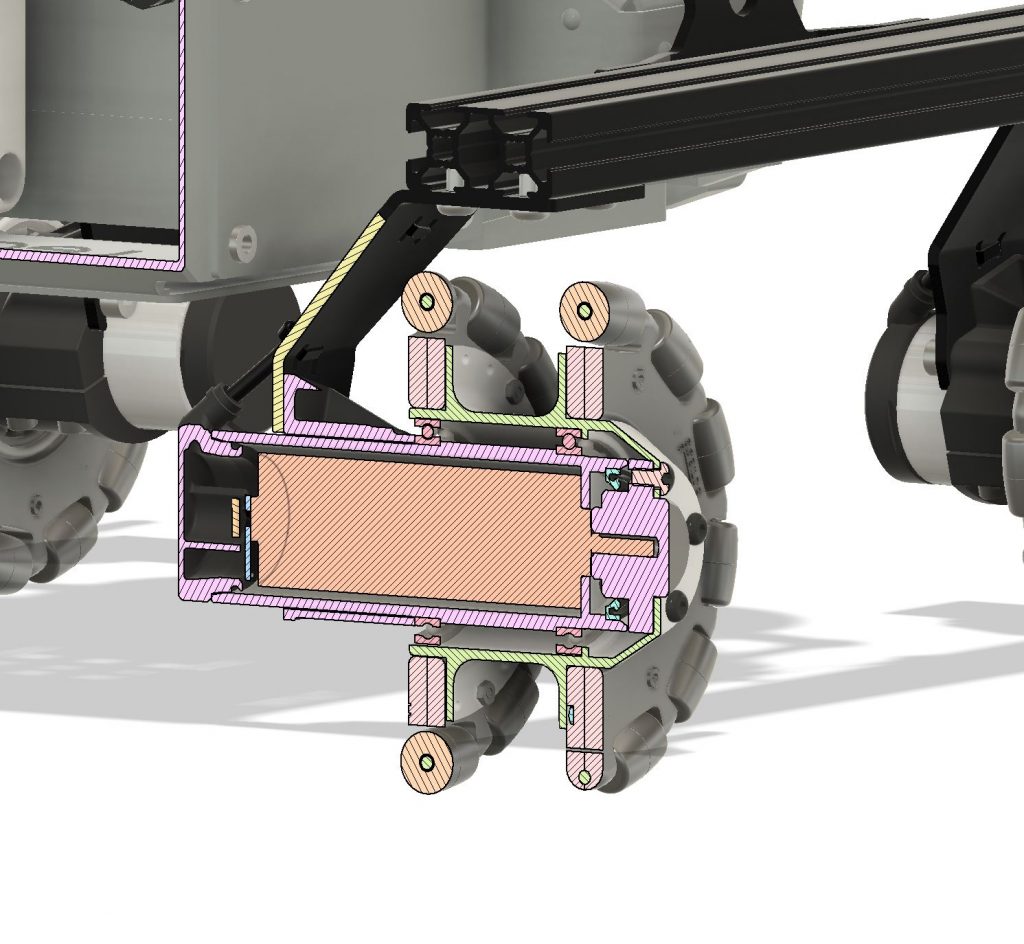

The New Hub will be 3D printed and bolts to the current Motor mount ‘lug nuts’ and positively presses against the front bearing with a small lip. It also wrests on each bearing to distribute the load from the new hub and wheels to the motor assembly.

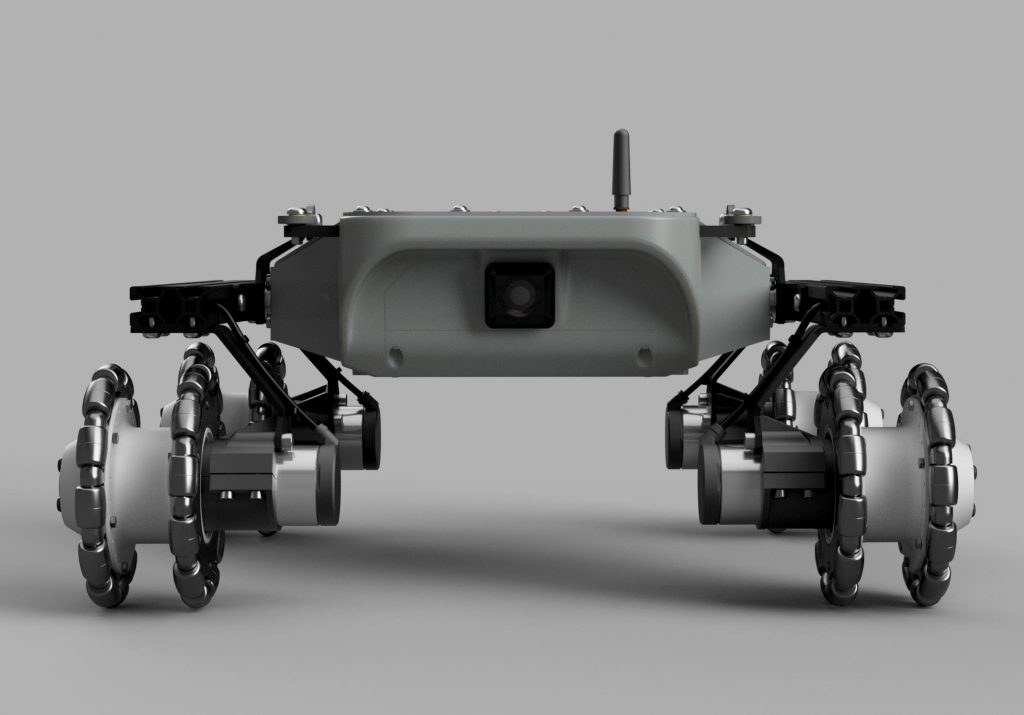

Here is what they would look like bolted onto the rover, note the two omni wheels are clocked differently to present a perfect circle to the surface and allow for smooth operation. The diameter of the new wheels matches that of the old tires, as well as similar tread width, to present a similar turning radius.

One item of note: One problem with Omni wheels in this orientation, is un planned sideways travel. The rover if on a slope can uncontrollably slide sideways for the un power wheels align on this axis. Being that this rover will be used on a flat surface with optical tracking I do not see this as a problem.

This design will allow for less strain on the motors and drive system, allowing for lower power draw in steering maneuvers, and prolong battery life. Also this will cut down on tire wear and allow the wheels to last longer with lots of steering operations.

I hear NASA calling!

Great idea!👍🏻