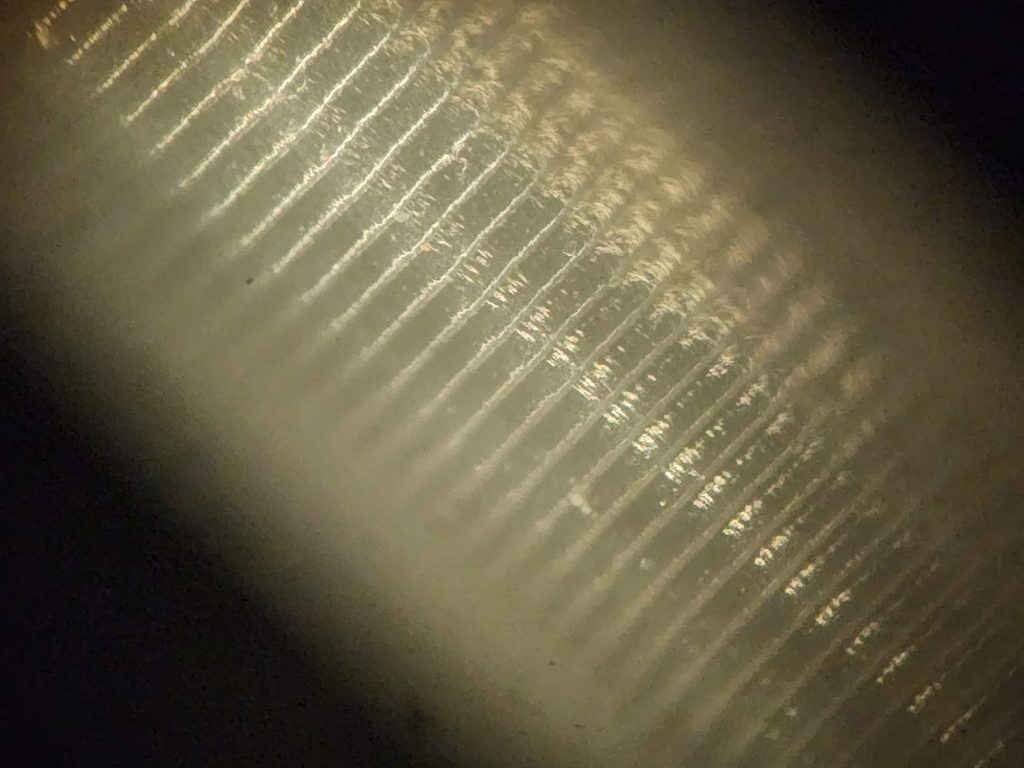

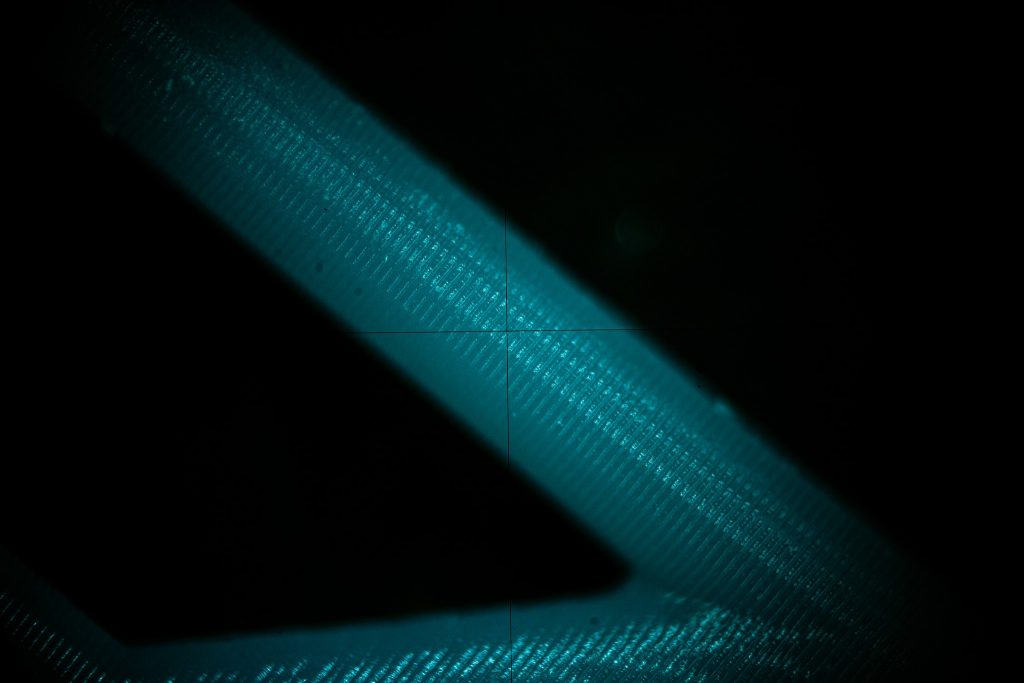

Every wonder what a high resolution resin 3D print looks like under a microscope? I was surprised to find the same layer lines you would find with a filament printer, but on a much, much smaller scale! the black line here is 1 micron across. these lines are not visible to the naked eye!

Resin 3D printers operate by utilizing a process known as stereolithography (SLA) or digital light processing (DLP), both of which rely on the precise manipulation of liquid resin and ultraviolet (UV) light. In these printers, a vat of liquid resin serves as the printing material. To initiate the printing process, an LCD screen or a digital micromirror device (DMD) projects an image of the desired object’s current cross-section onto the surface of the resin. This image masks certain areas of the resin, blocking UV light from curing them. Meanwhile, the unmasked areas are exposed to UV light, causing the resin to solidify or cure, forming a single layer of the printed object. Once the layer is complete, the build platform moves slightly downward, and the process repeats, with the LCD screen or DMD displaying the next layer’s image onto the resin surface. Layer by layer, the object gradually emerges from the resin vat, with the cured layers bonding together to form the final 3D print. This precise and efficient method enables resin 3D printers to produce highly detailed and intricate objects with exceptional accuracy and surface finish.

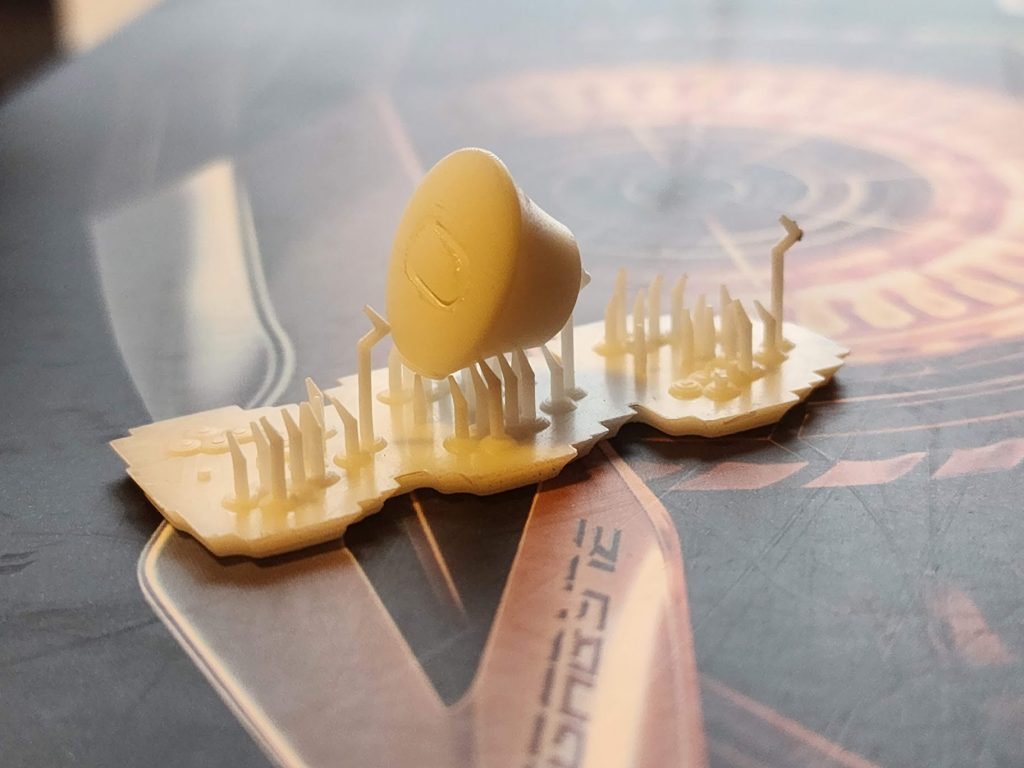

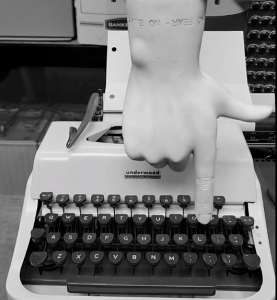

The Bars bellow are from the small support rods for the key caps I printed for the Monroe calculator!