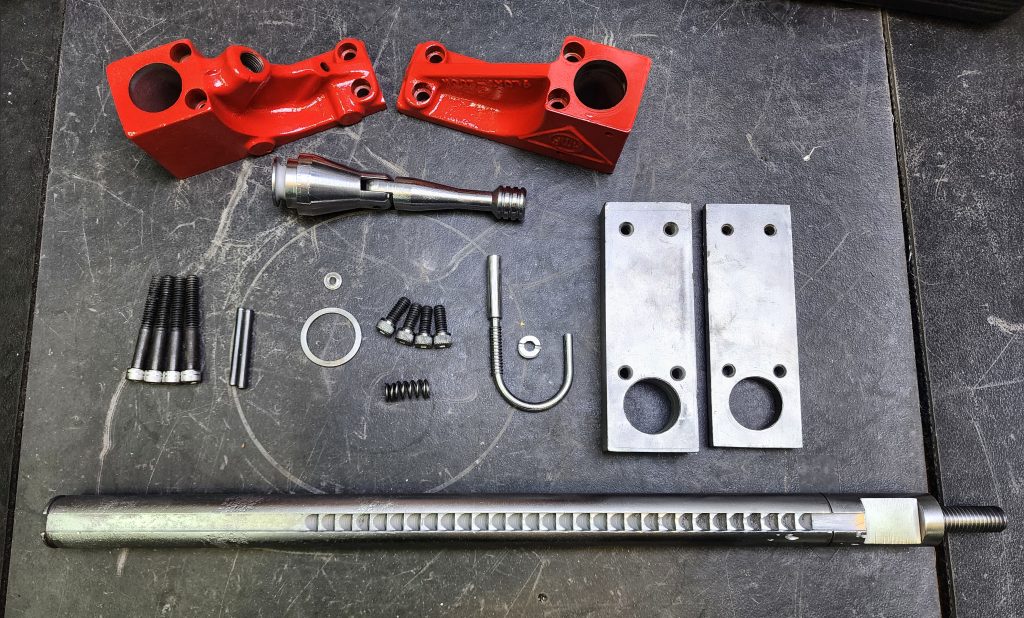

Got this vise recently it was locked up and rusted solid. All the ‘aprentice marks’ or holes drilled in the jaws, I weld filled and re ground. I left some of the smaller nicks so it still looks used. For the main jaws I re surfaced the faces to paralell, but without a milling machine, I could only go so far, so the deep chunks will have to stay for now. I went with safty red instead of the traditional safty yellow, so it stands out.

Here is everything after some time with the sandblaster and whire wheels.

The jaws had some deep chunks and holes, that I had to clean up.

Now I can get everything painted, and ready for reasembly! The ring lock pin, was bent, and would not move smooth, some had to spend some time with the vise to get the ring flast and in the right shape again, works great now!

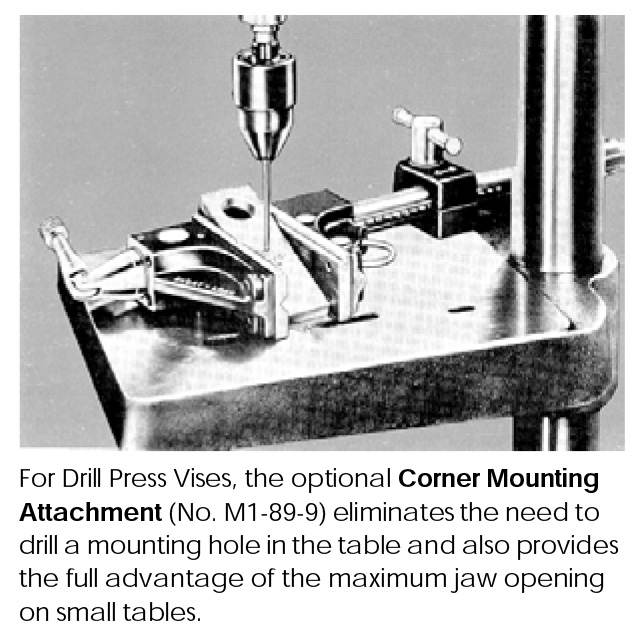

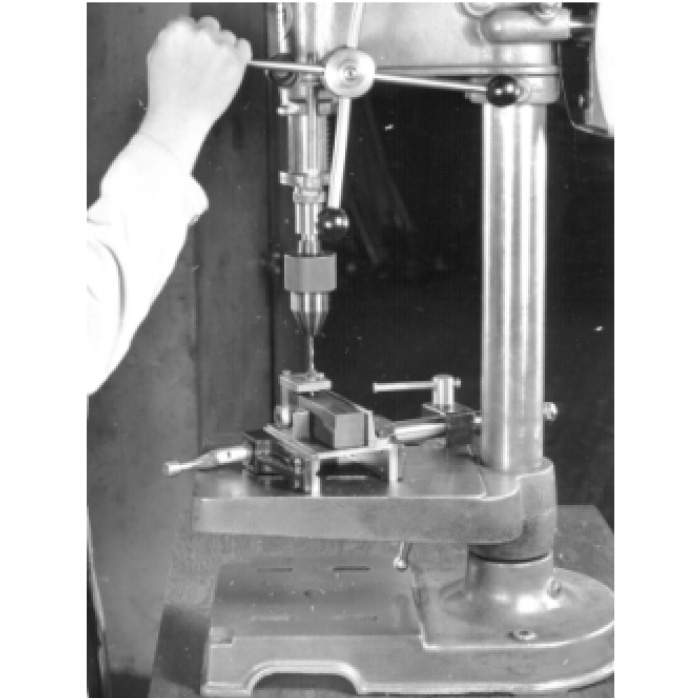

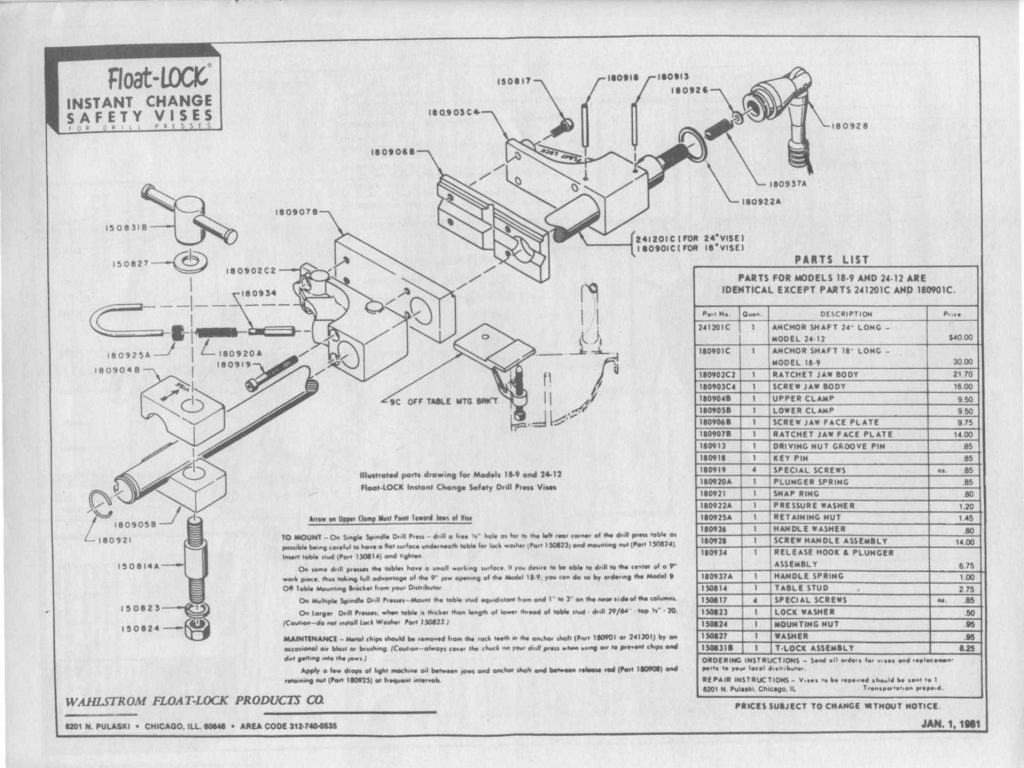

All that is left is to hunt down or make a new table clamp for it as shown here.