June 6th 2015 this all started with a fantastic find. I got a lead on a forgotten old CNC machine headed to the scrap yard. The unit had all its wires cut, was missing all the electronics and controllers and was at some point hit with a forklift in the past and knocked out of square. The best part? It was free if I hauled it away!

Well being that this page is here, you already know the outcome, I could not get out there fast enough to pick it up!

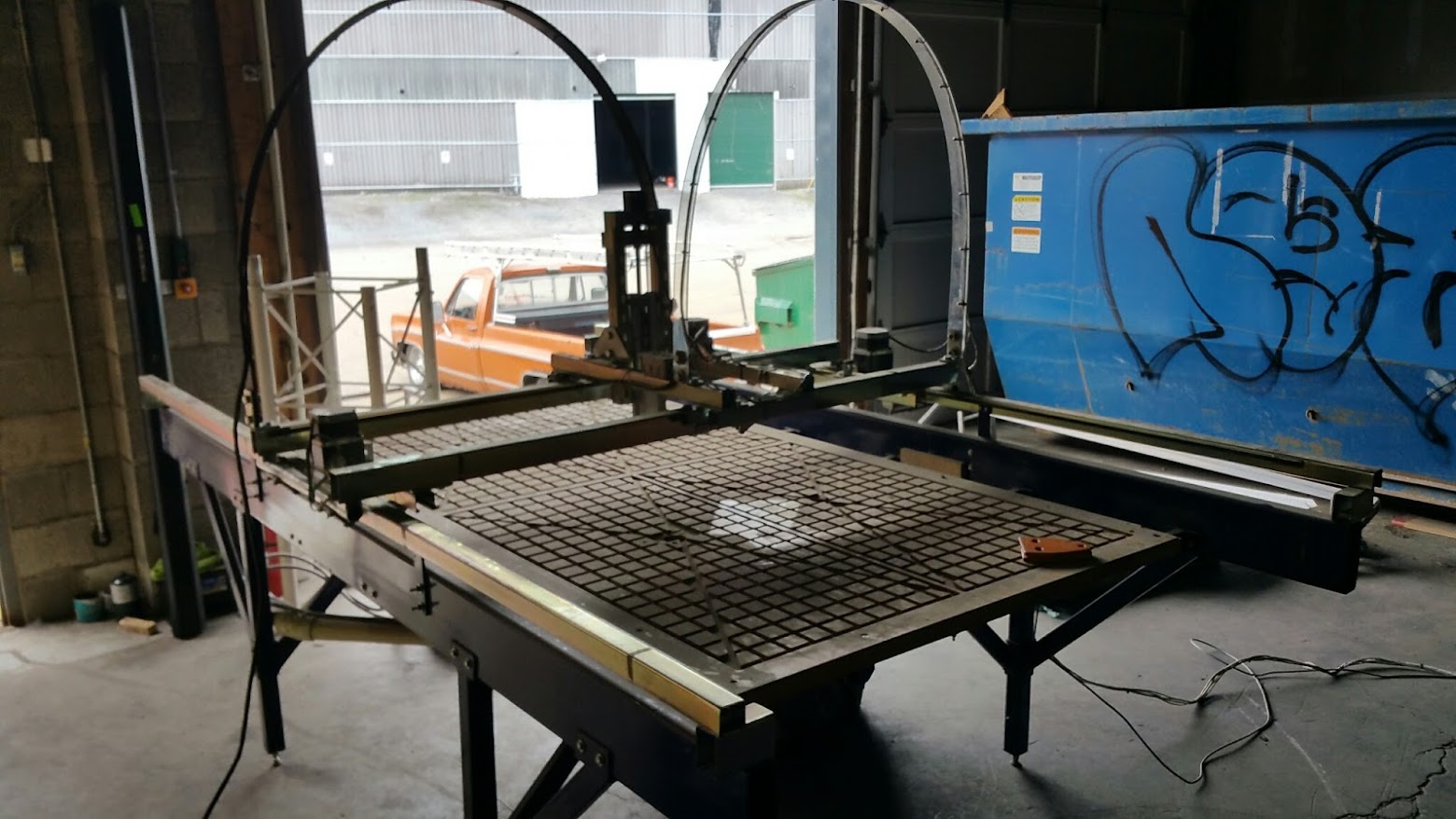

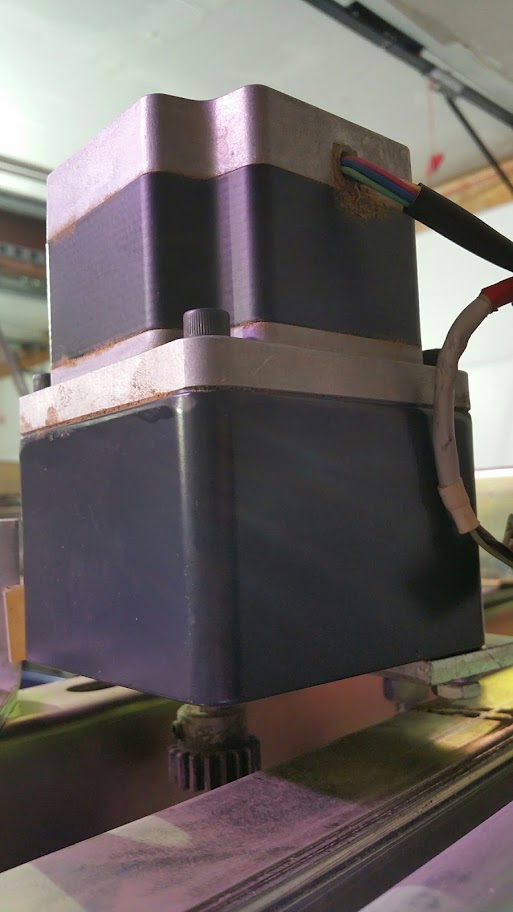

Here it is all unloaded, was a huge amount of work not having a forklift in the shop! It is a massive 5×10 table size. ( Did not look that big in the photos! ) After some googling it looks to be a old.. very old ShopBot first generation CNC router. Dubbed the ‘unistrut’ edition. Even the company will not admit they made this model ha. In CNC years this thing is an antique, back when new it ran on Win95! There was not even motor controllers back than, just dumb motor drivers with quadrature input. So in a way a blessing I did not get any of the old ‘controllers’

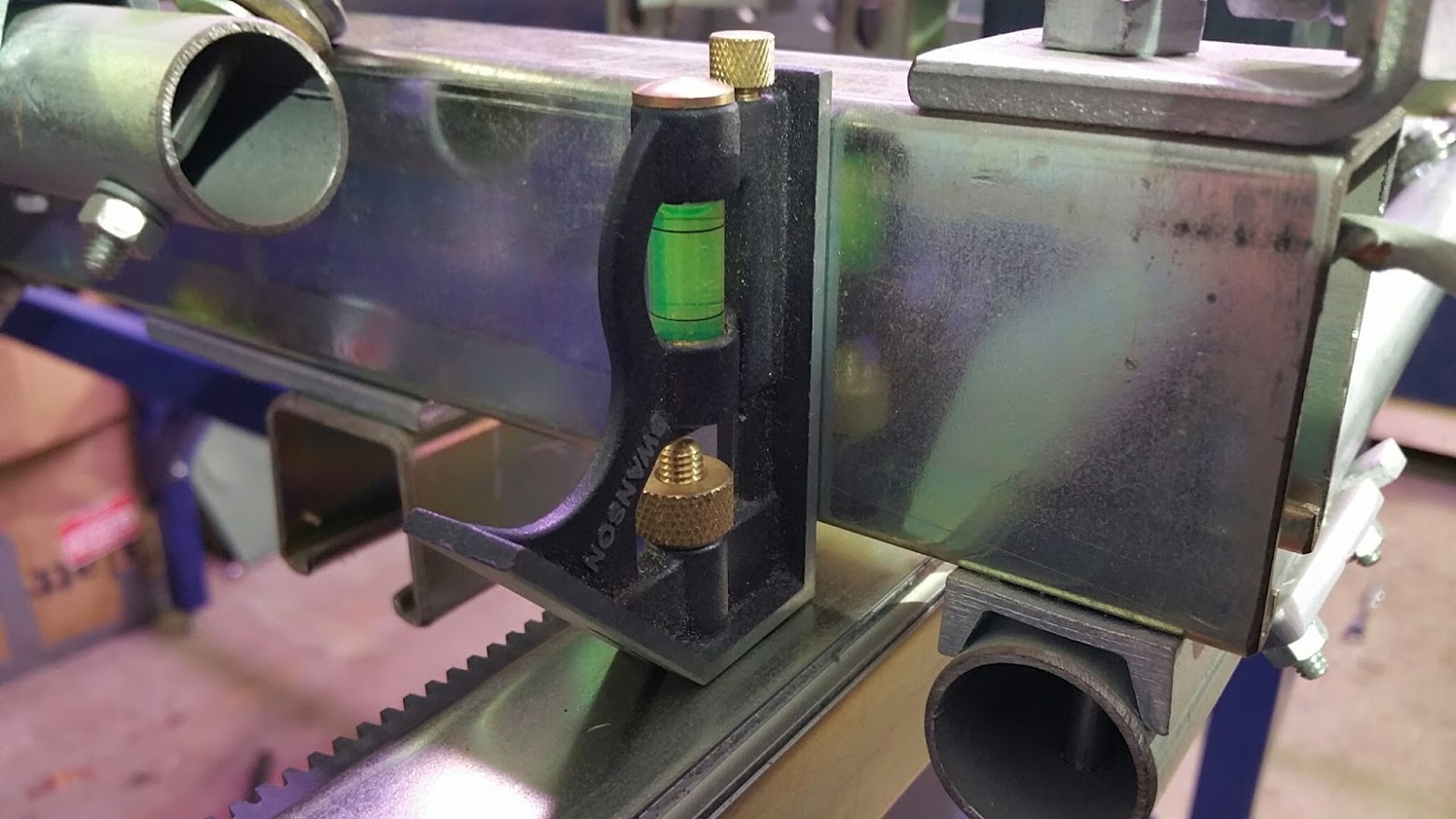

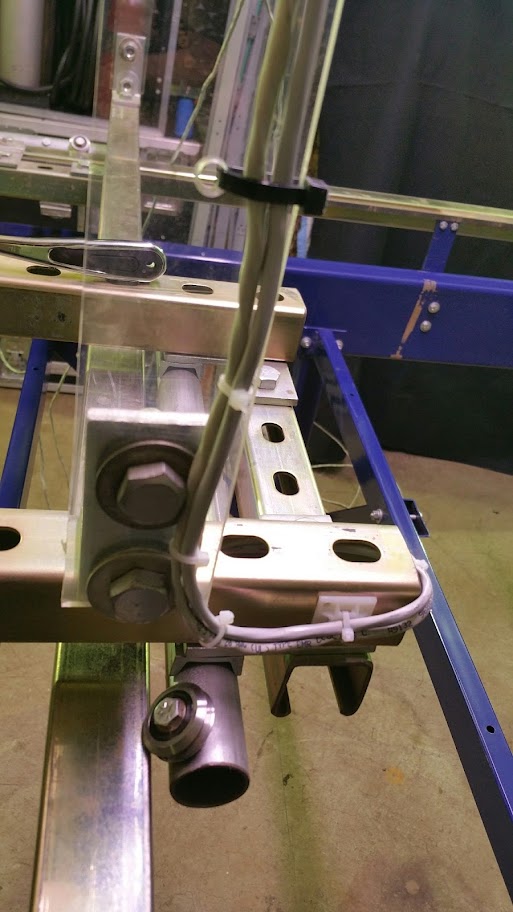

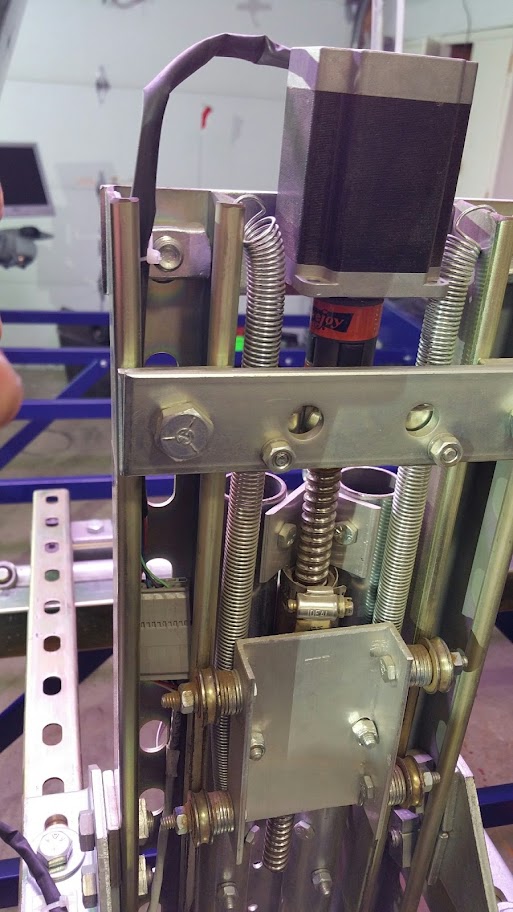

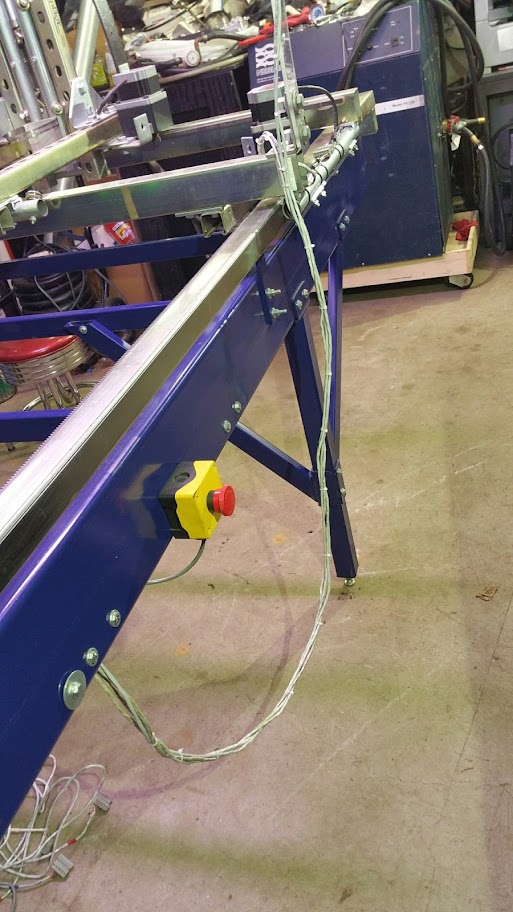

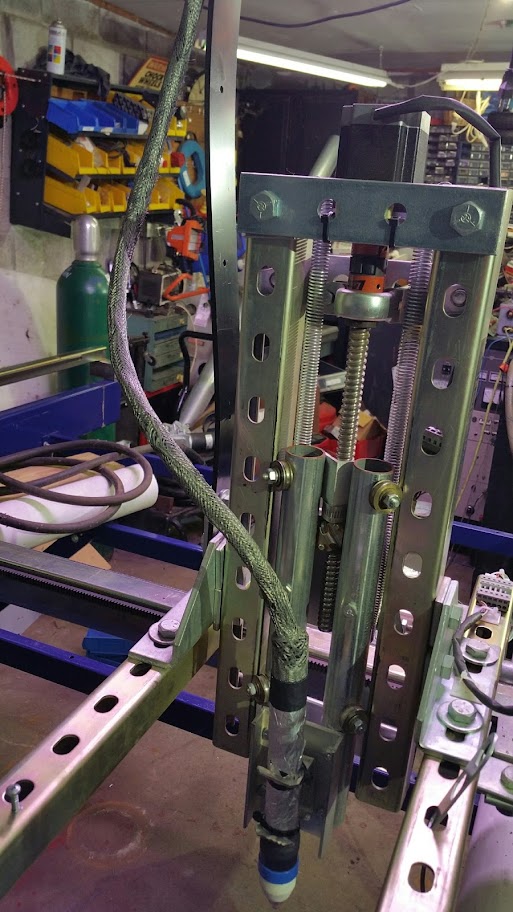

The gantry would not even move when I first saw it for being so out of square and adjustment. I spent the better part of a week cleaning and fine tuning the structure, and getting things into perfect square and level, I also redid all the motor wiring. Found and mounted a monitor and keyboard arm to mount to the end to hold the interface.

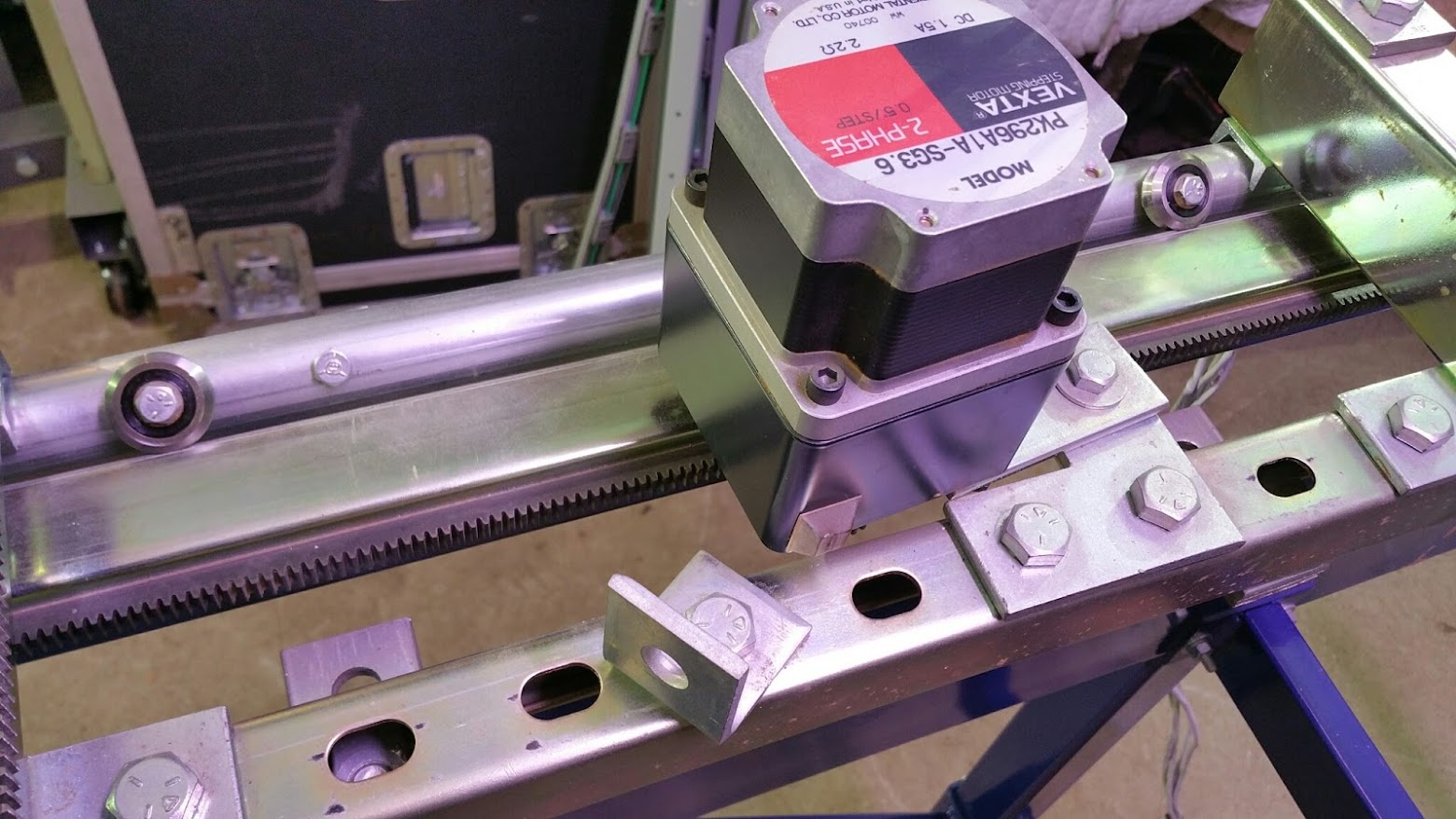

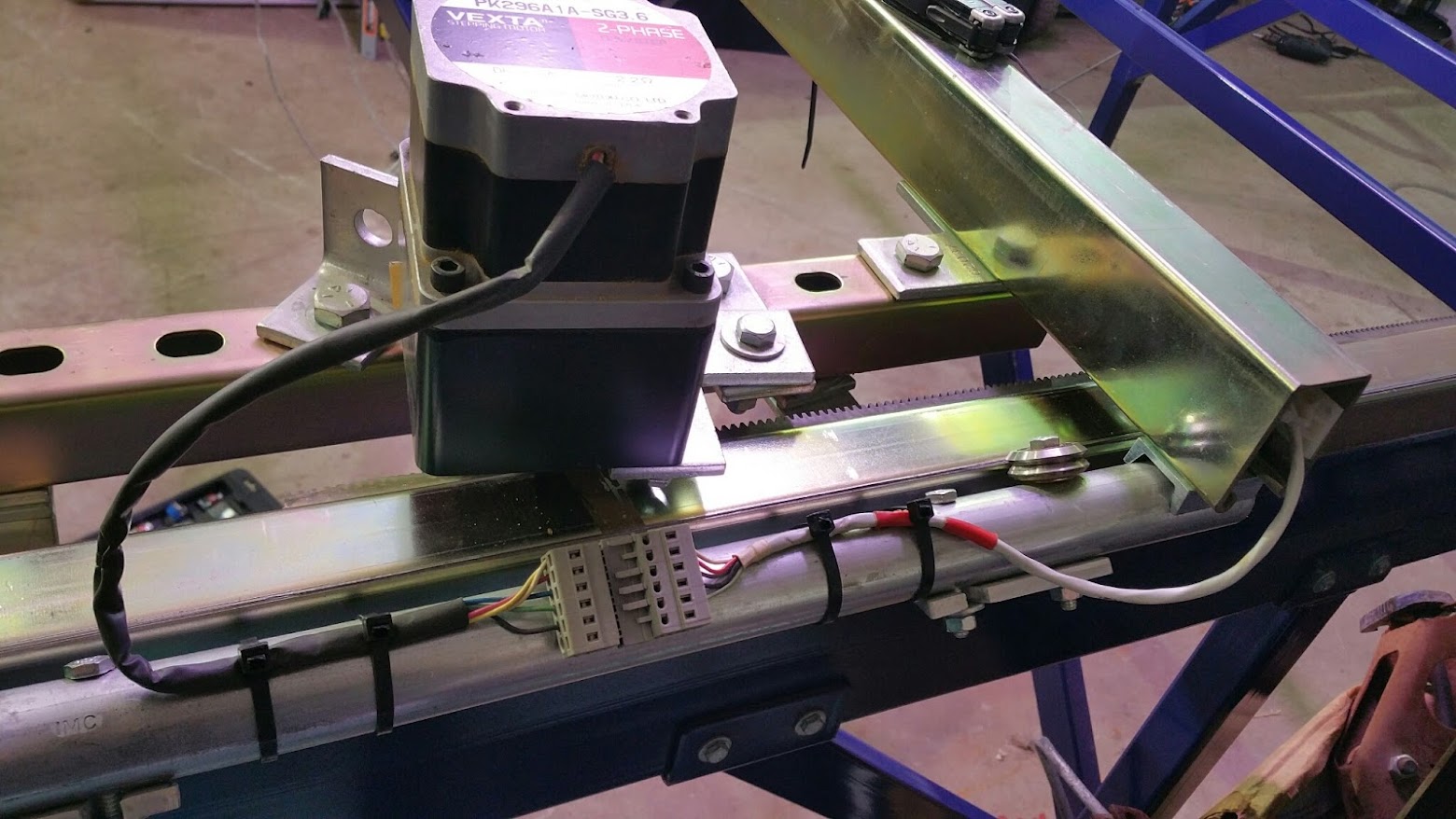

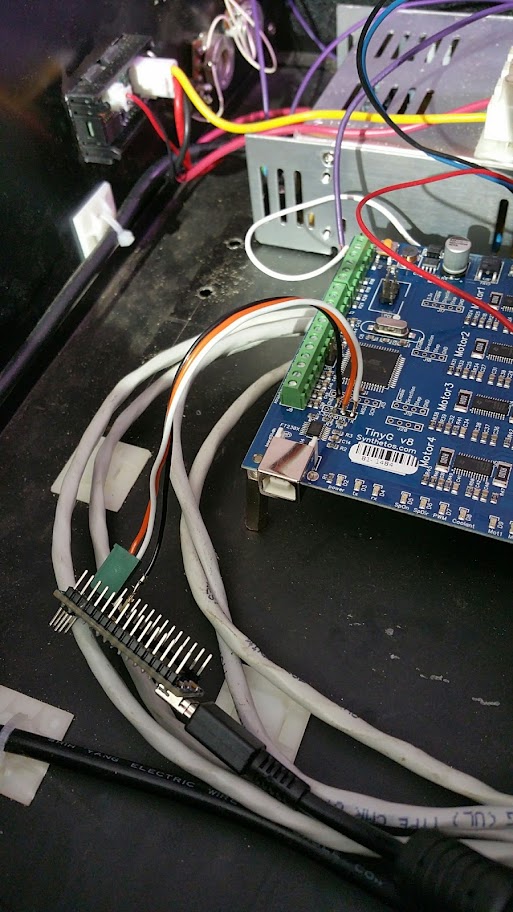

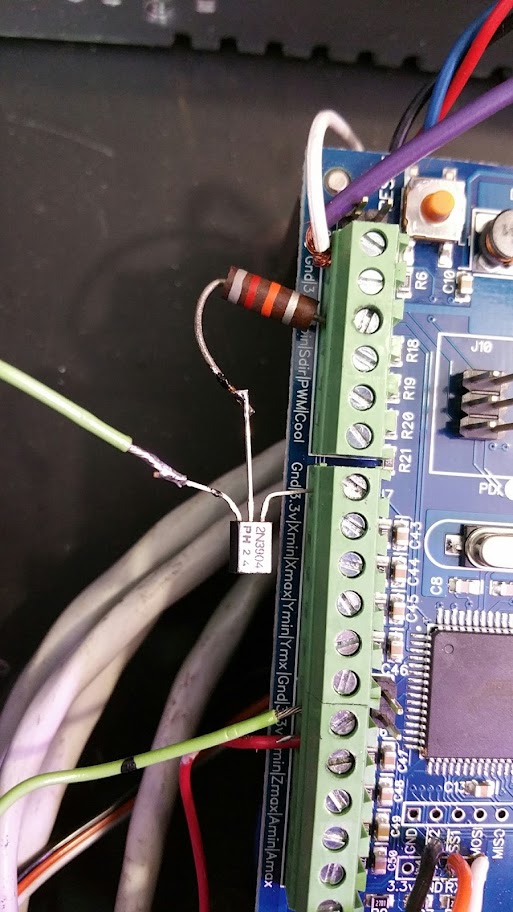

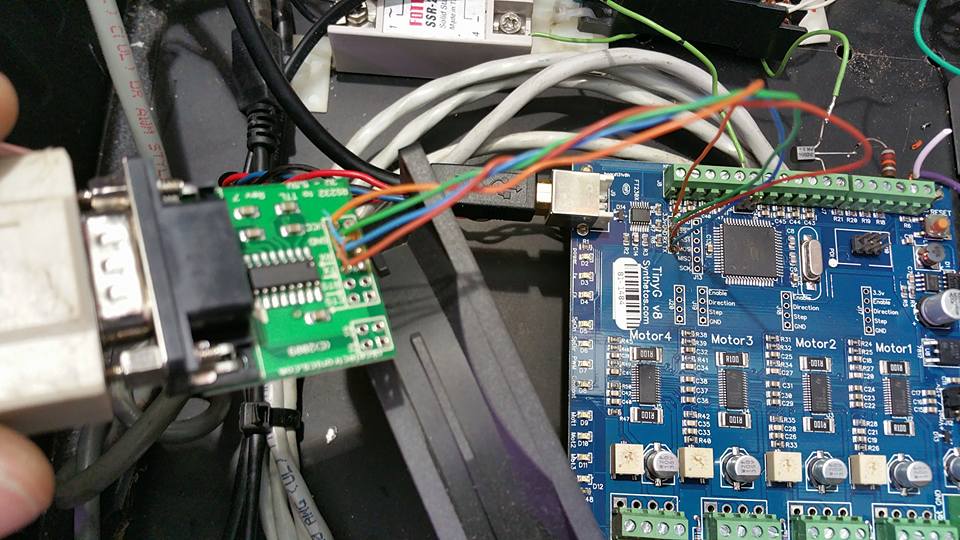

Next I needed a new controller.. Something that would not break the bank. For I was still not sure this would work, had no idea if the motors where still good even. I chose the TinyG An obscure all in one CNC controller for the DIY’er. https://synthetos.myshopify.com/products/tinyg

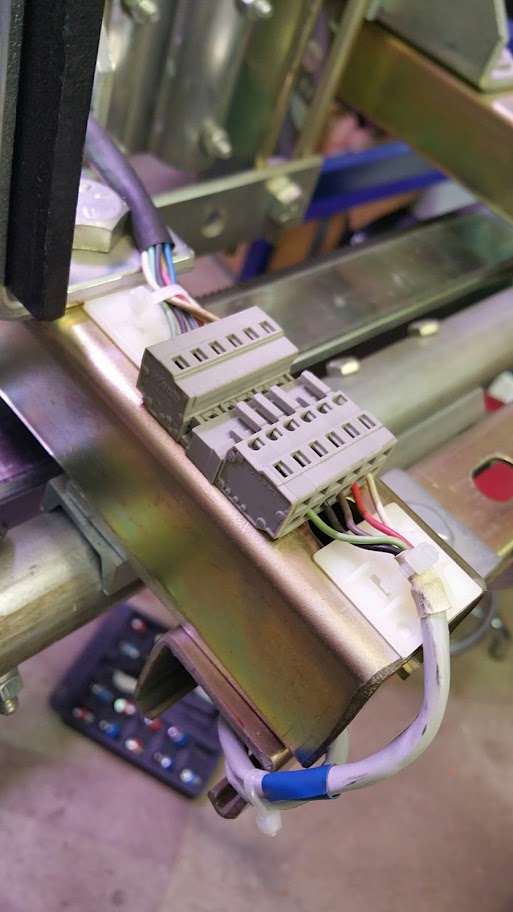

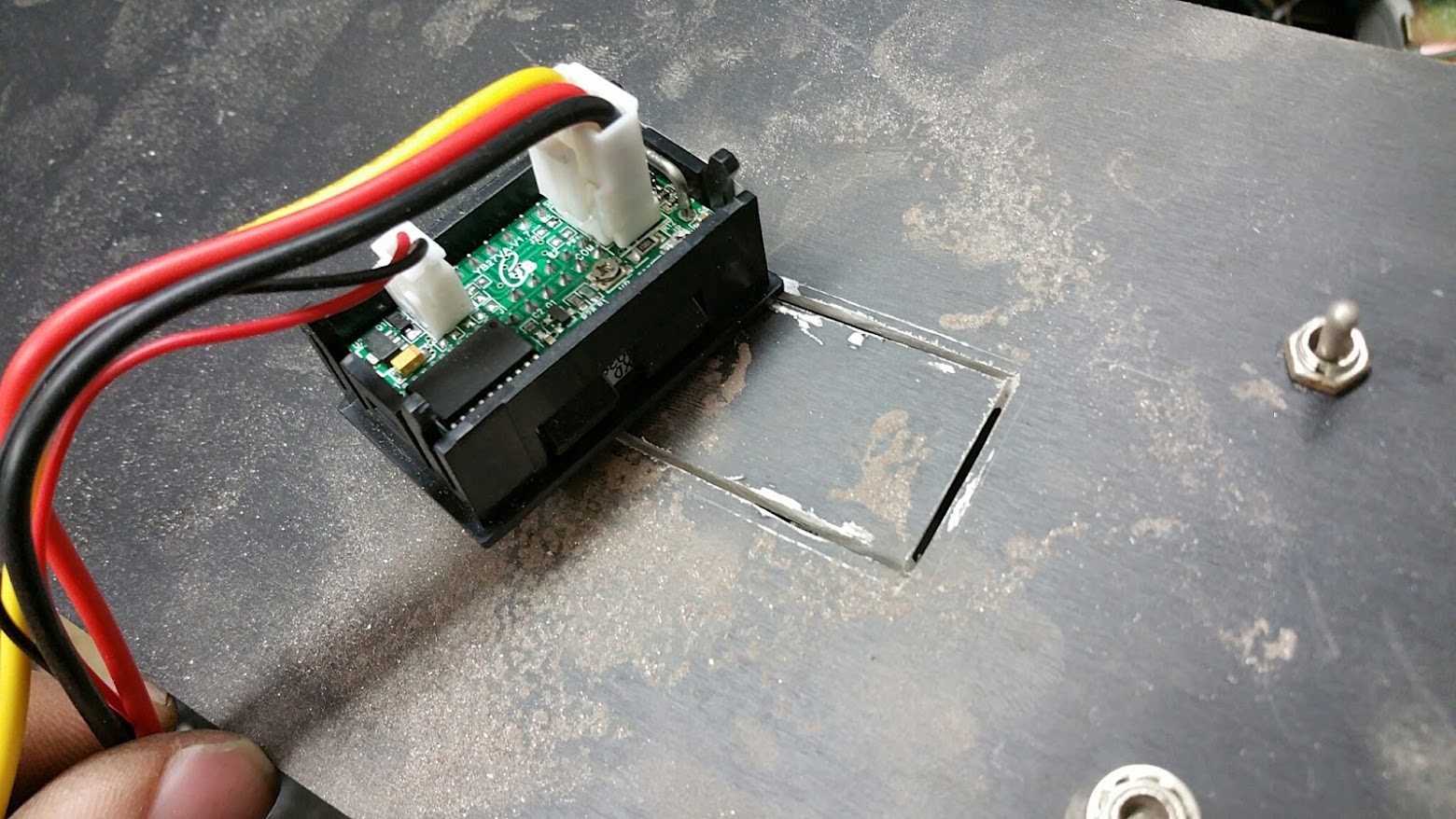

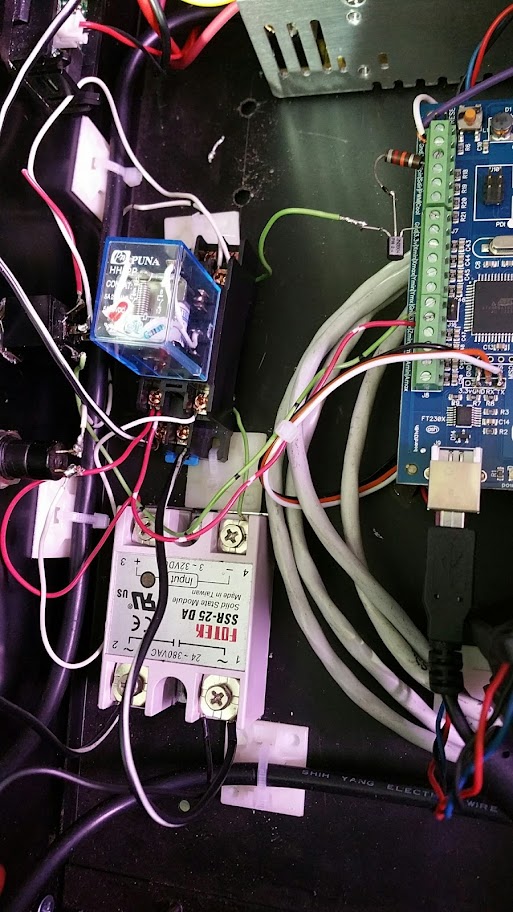

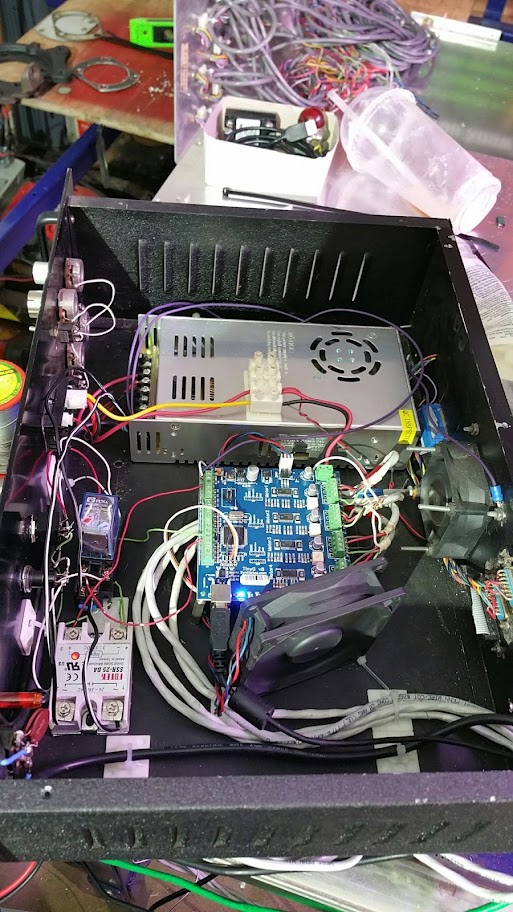

This controller proved to be a real powerhouse and was able to run my large Vexta motors well. So I built it into a case and wired it up!

Here is a walkthrough,

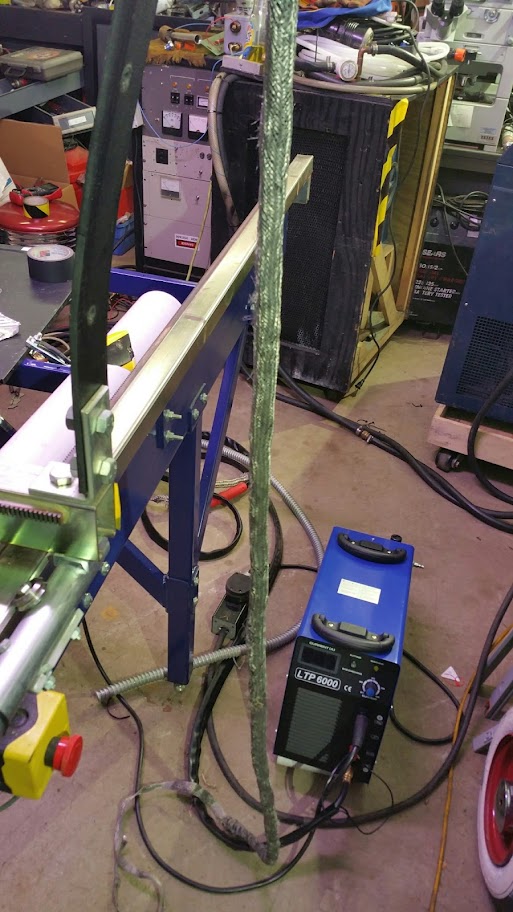

Now that I know it works and moves, time to get a plasma cutter!

I picked up this Lotus LTP 6000 60 amp Plasma cutter with Pilot arc. Why this one? Because it was the cheapest one I could find that still had IGBT drives. ( better quality ) It also had an external jack for the ‘trigger’ so I knew I could remote control it.

The last time it will ever be used by hand ha!

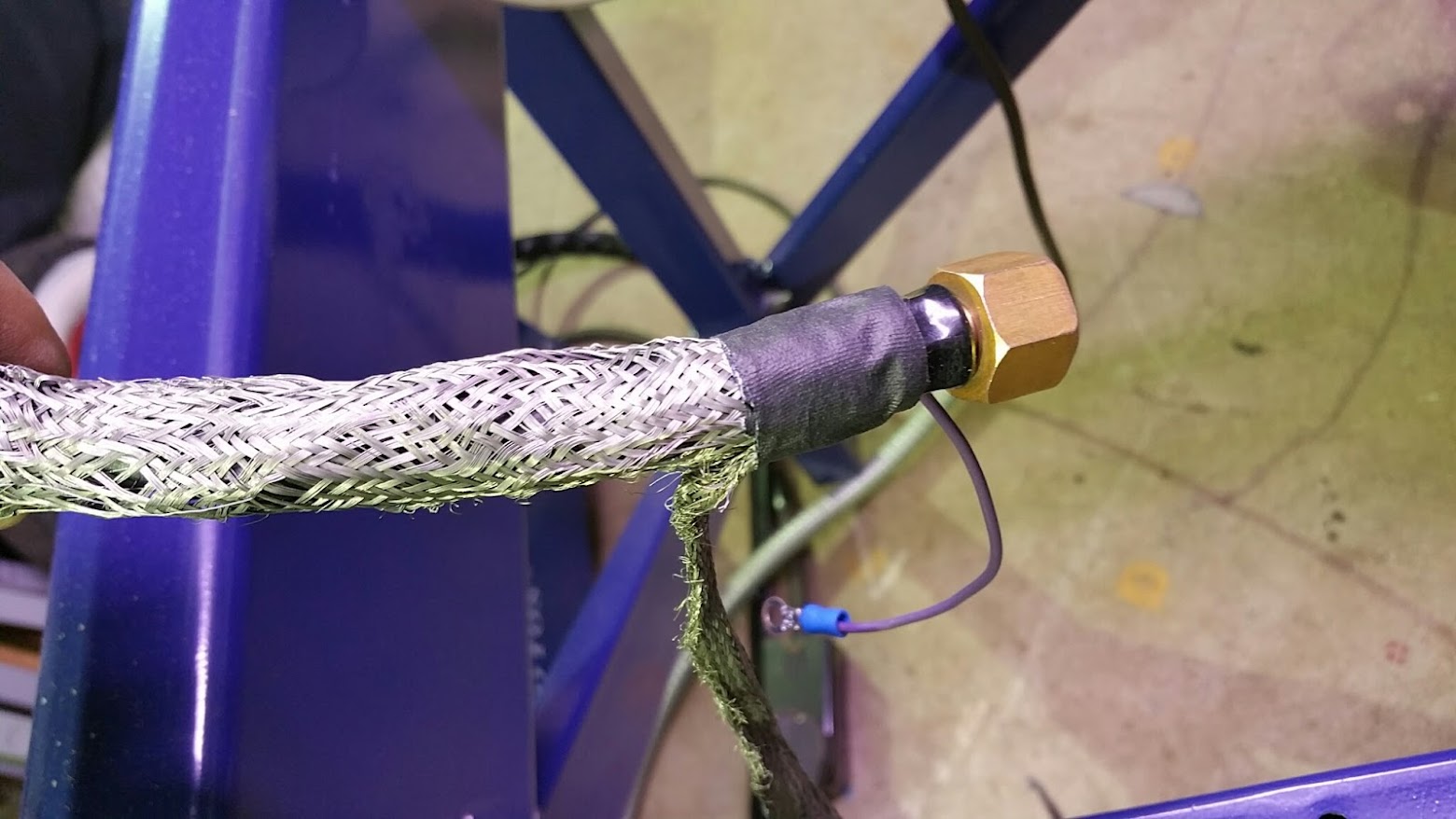

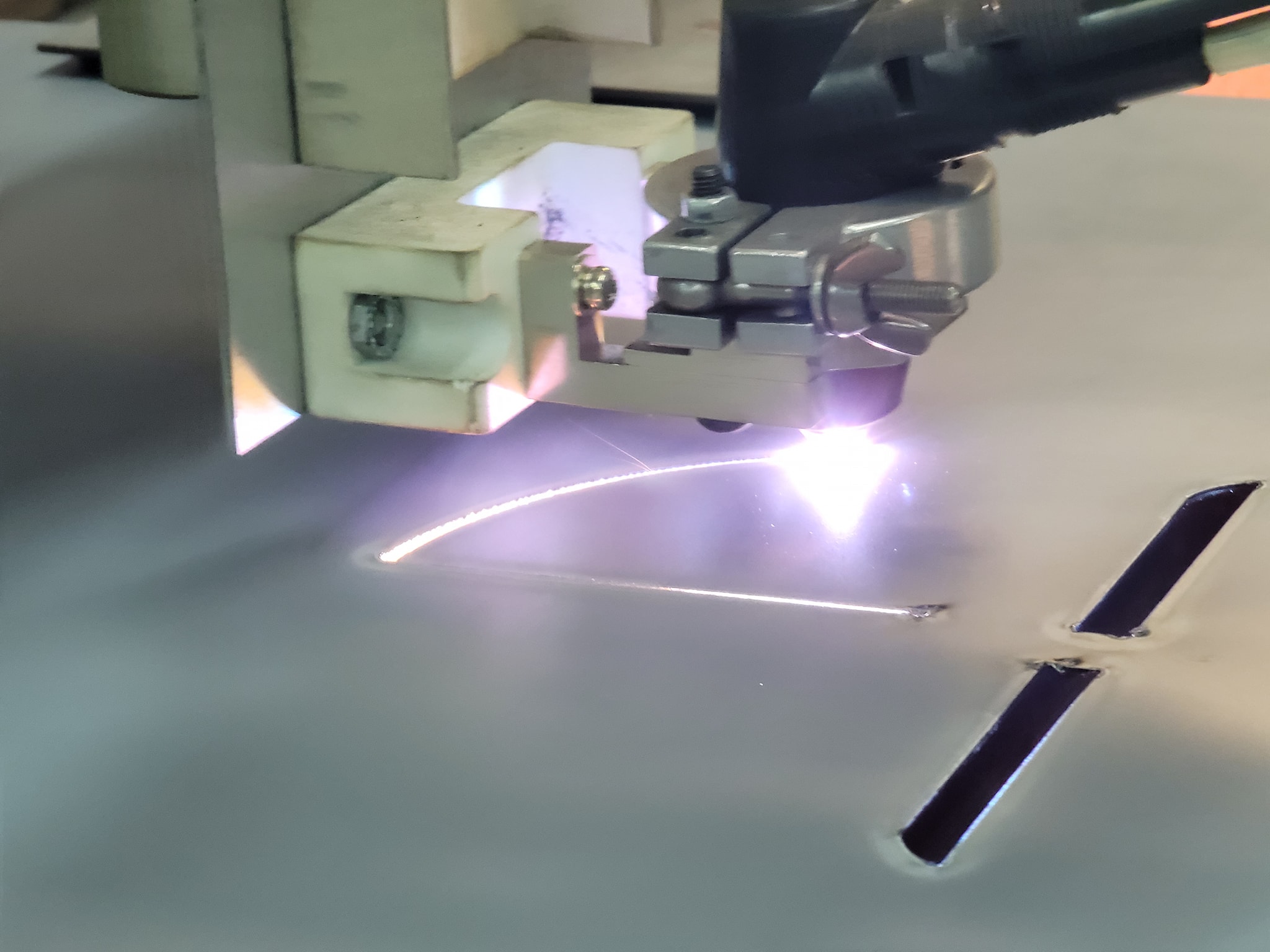

Awesome, now off to the races? not so fast, the pilot arc start on the plasma generates a huge amount of electrical noise. Like enough to flicker the VGA signal to the monitor on the PC. Well this was cuising a ton of problems with my CNC controller and it would lose communication with the PC and lock up mid cut!

Man did I try everything to prevent this noise lockup problem. I even went as far as to shield and ground everything, still had problems. I also even tried a new torch setup, also no luck….

They always say newer is not always better, well, I had to bypass the USB to serial converter, I soldered in my own RS232 Serial to TTL converter and ran it to a hardware serial port on the PC. BAM! This fixed it, all my problems went away! Awesome! I can now start fine tuning everything!

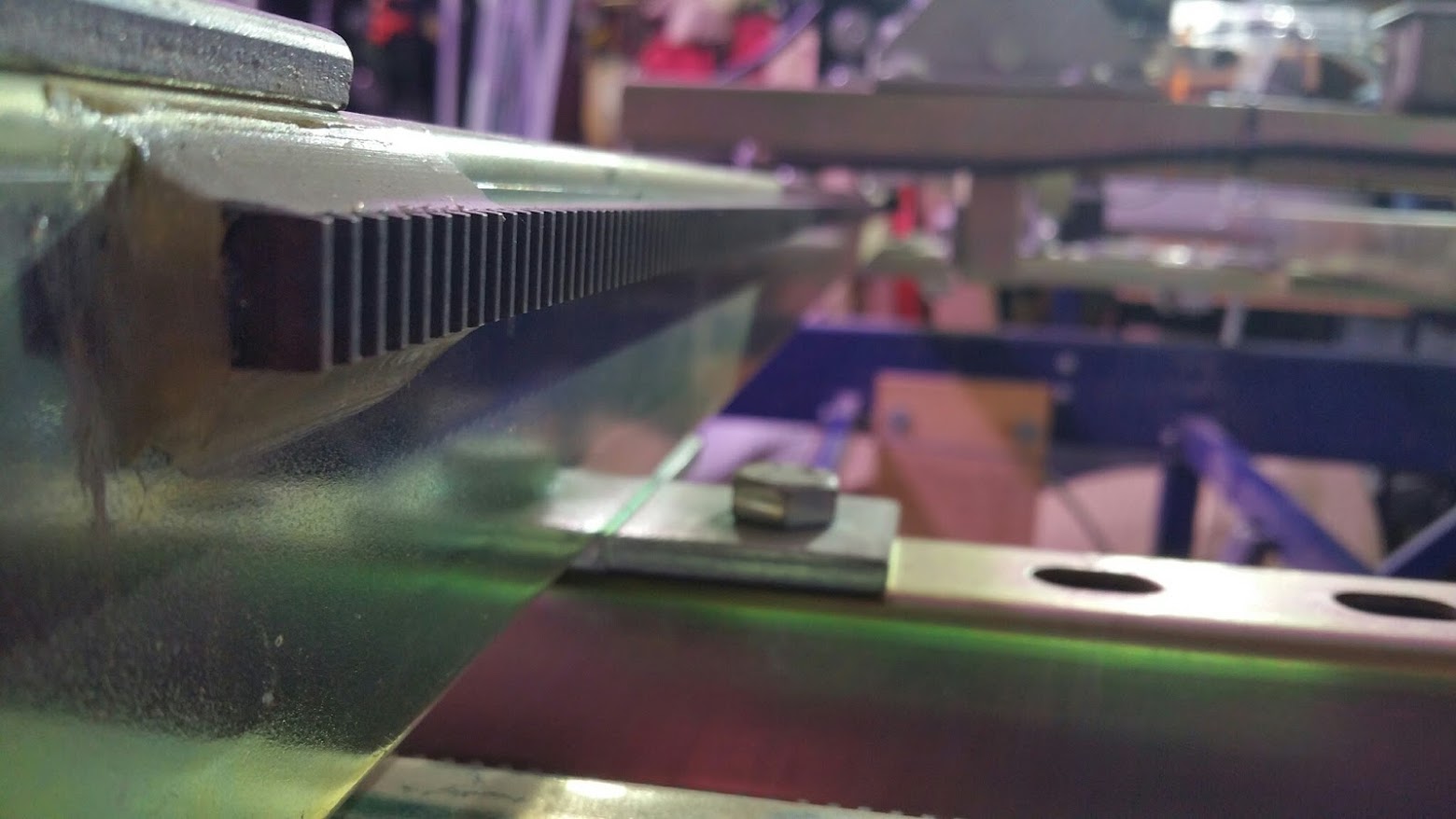

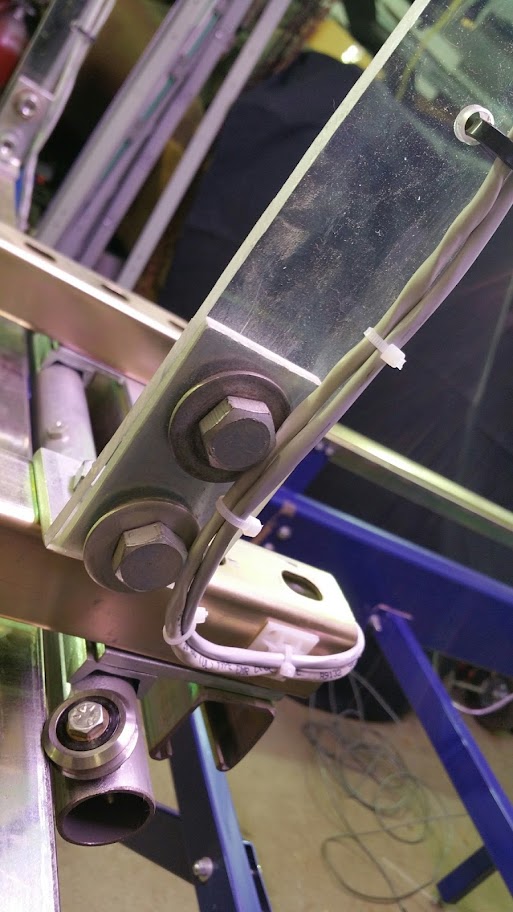

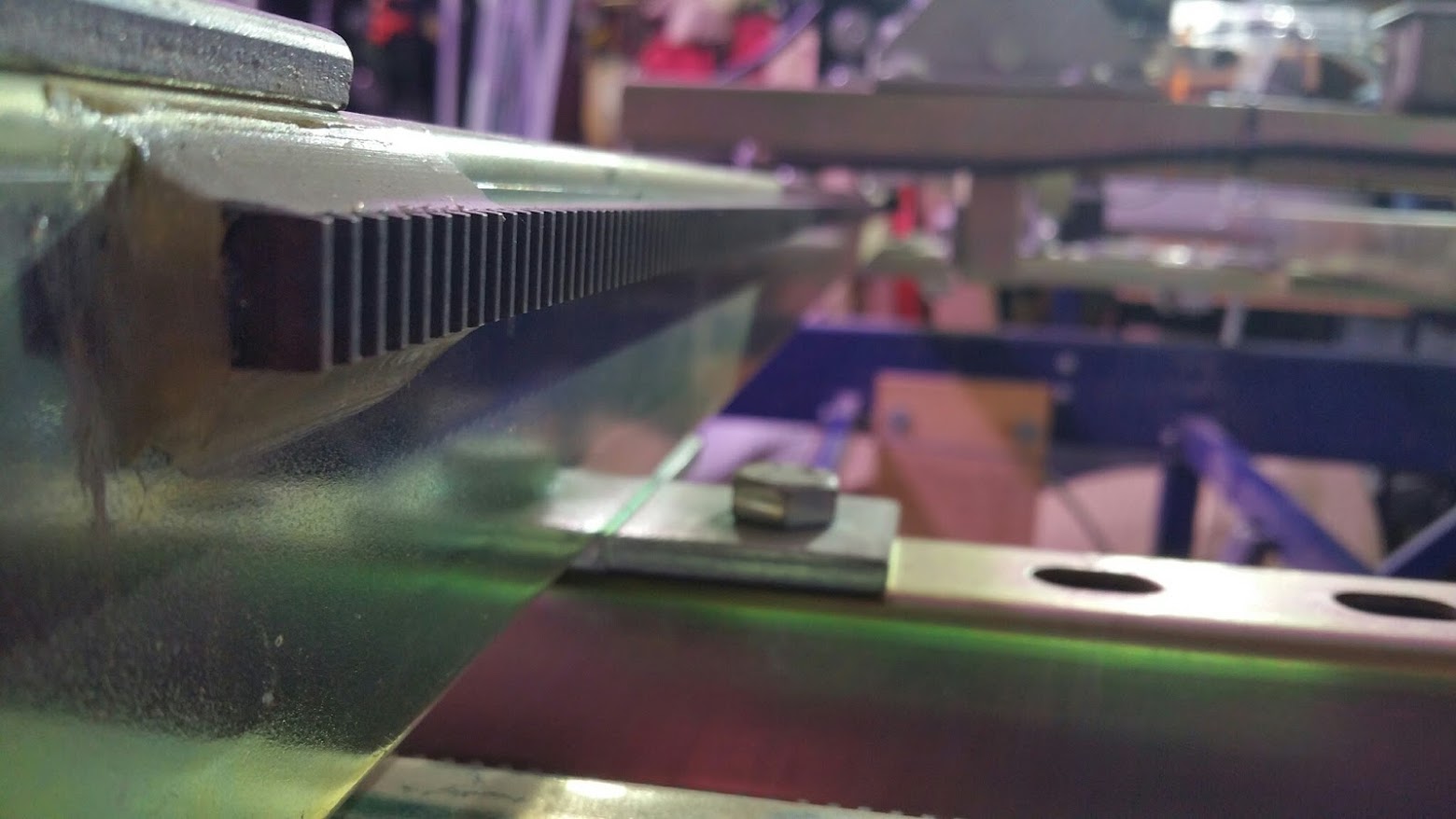

The old wheel on strut system was not holding up well, so installed some new guide rails down each side, over 100 bolts later, she runs so much smoother now. I ended up installing 4X gude wheels per side to keep thing square.

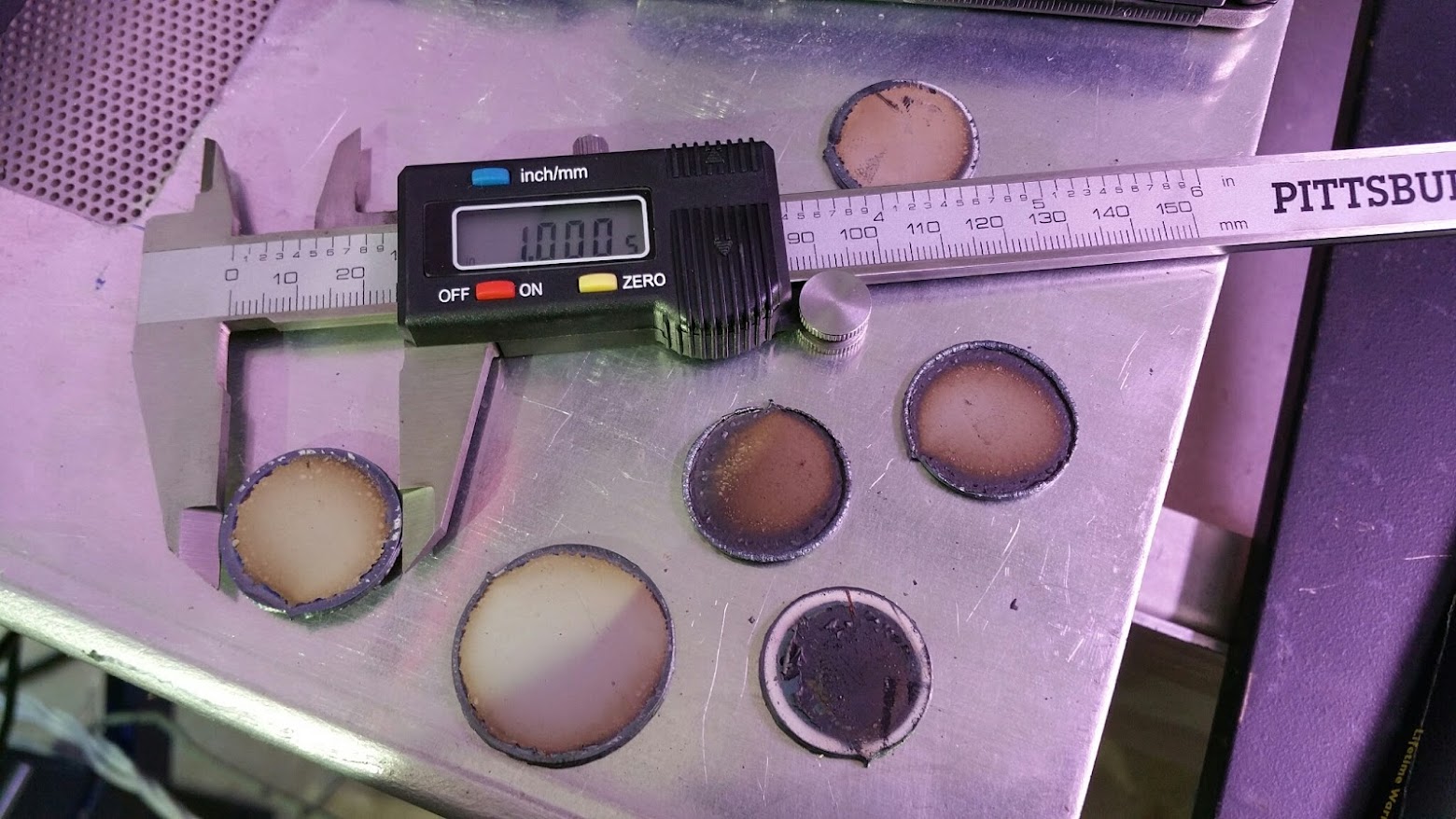

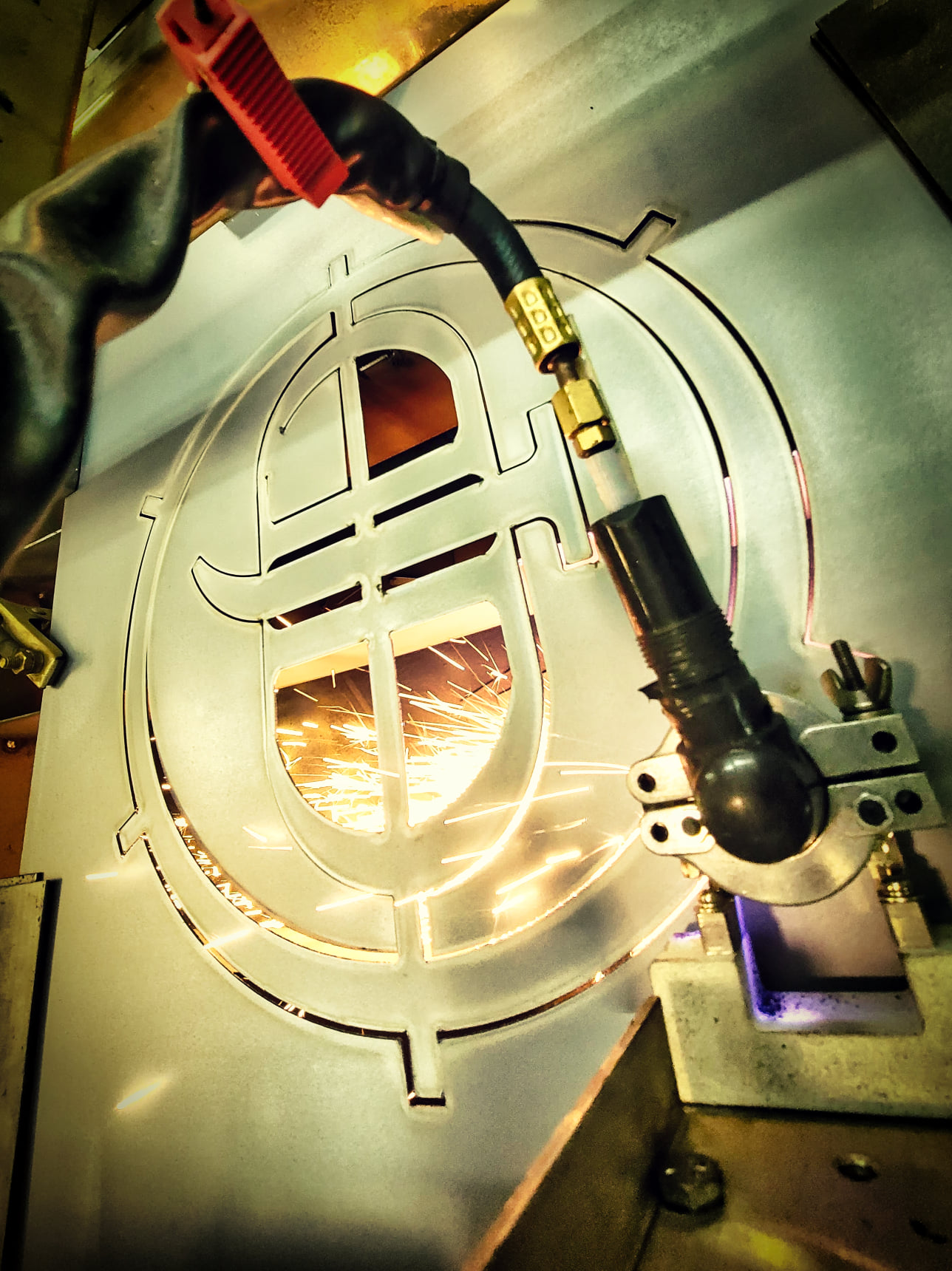

Not knowing any of the parameters of the machine, I had to hand dial in the settings, so lots of 1″ circle cuts to test settings, I finally got it dialed in to be as perfect as plasma can be!

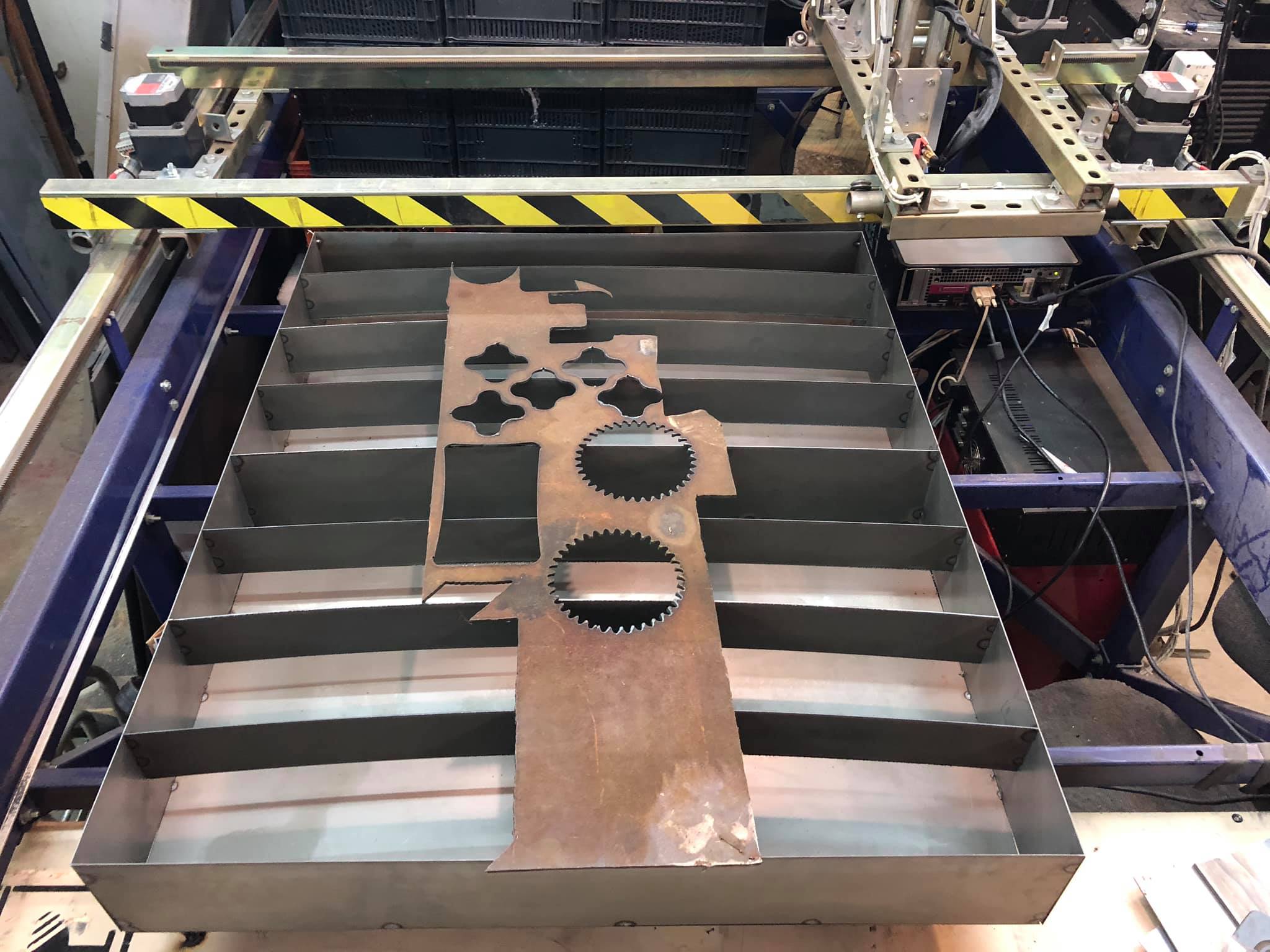

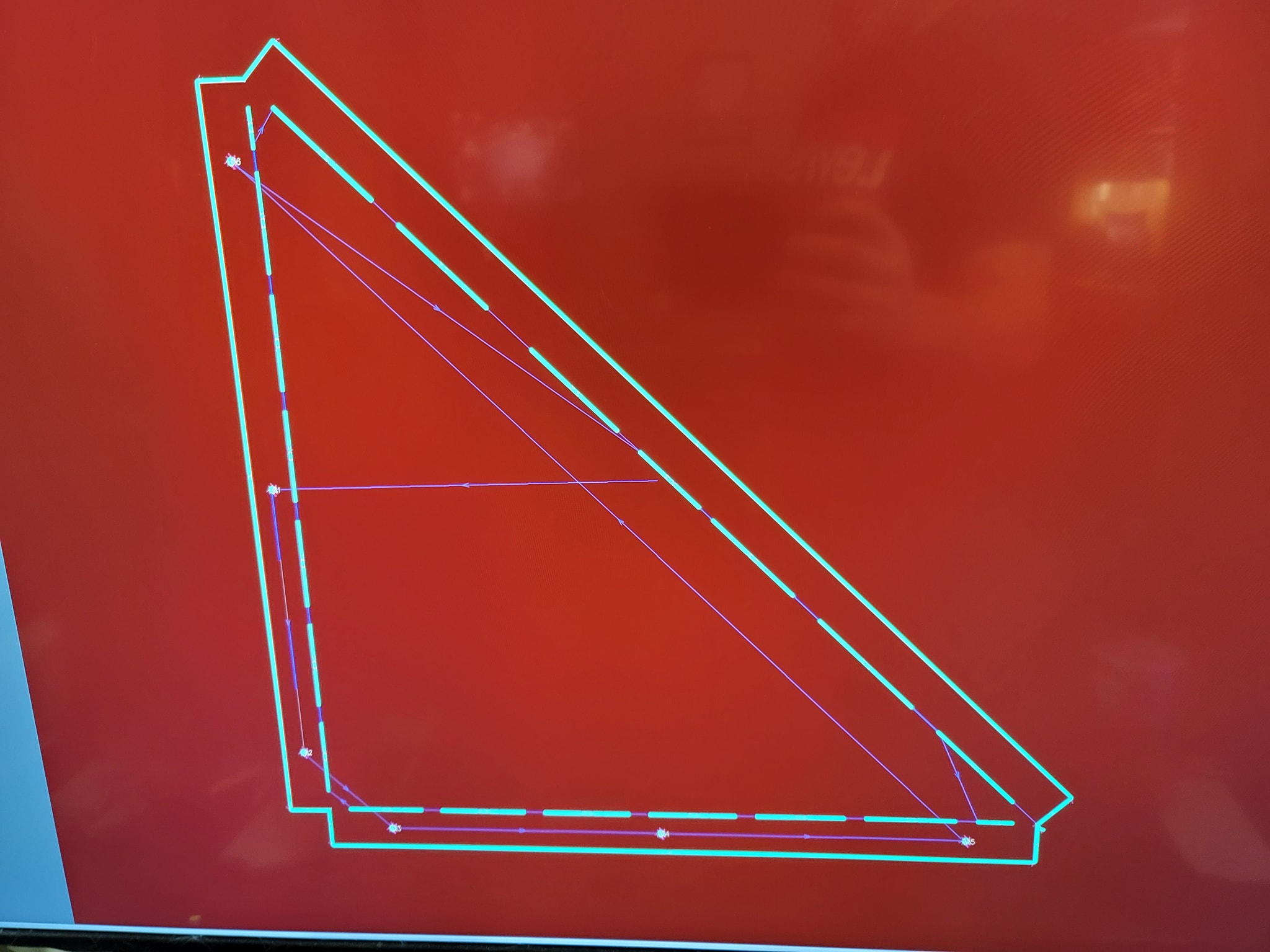

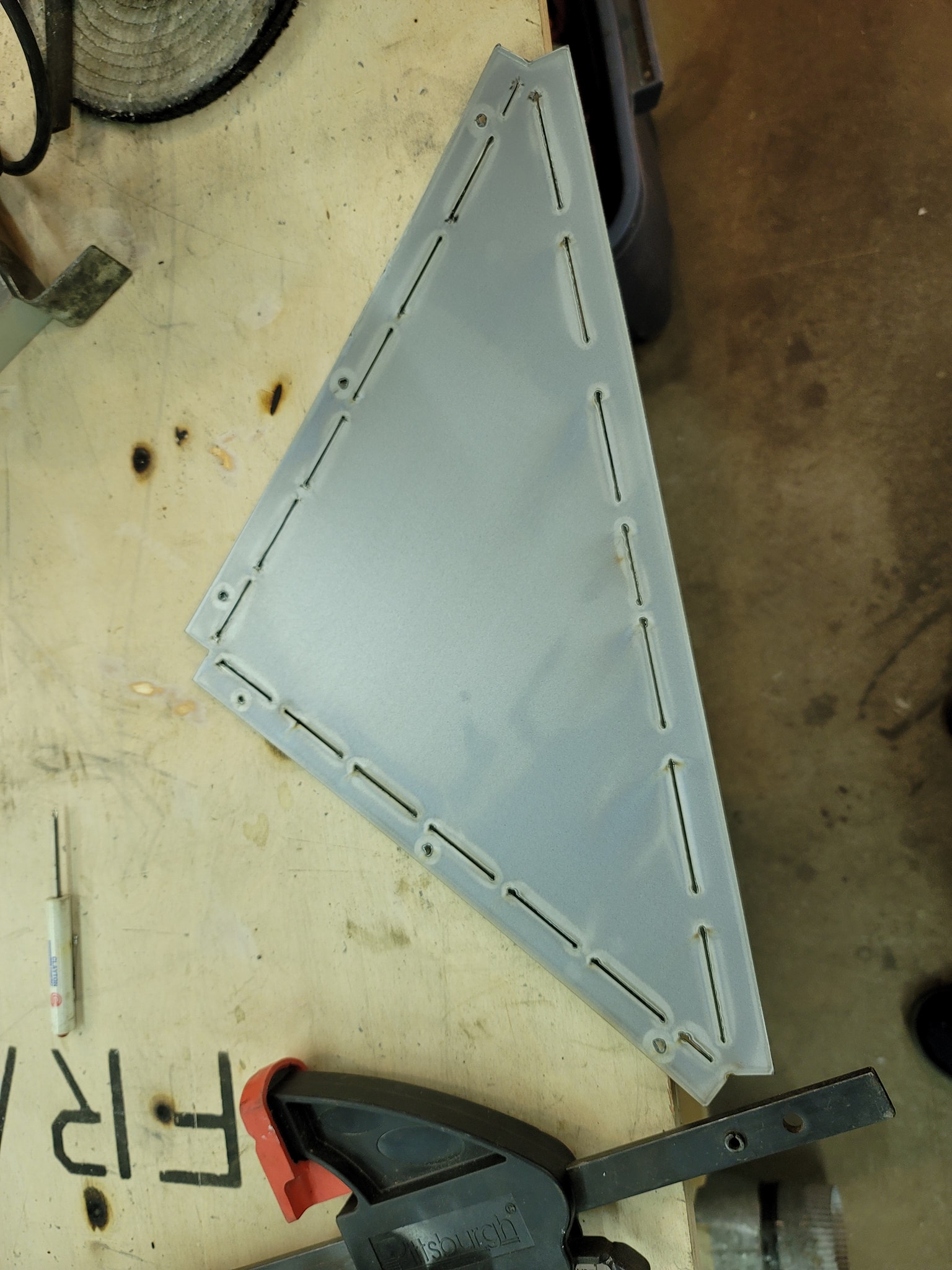

This was a full size of table test run to make sure accuracy holds.

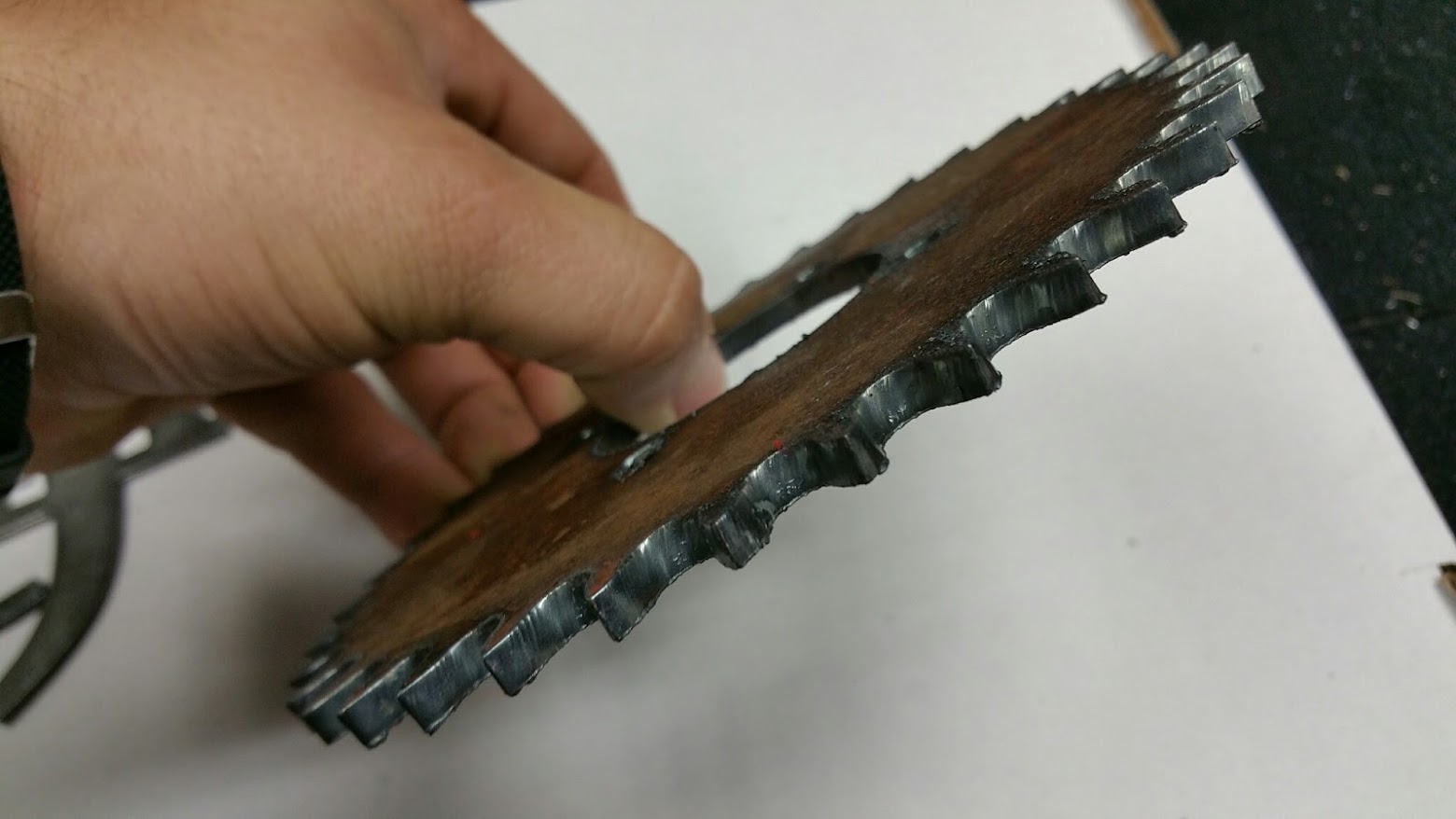

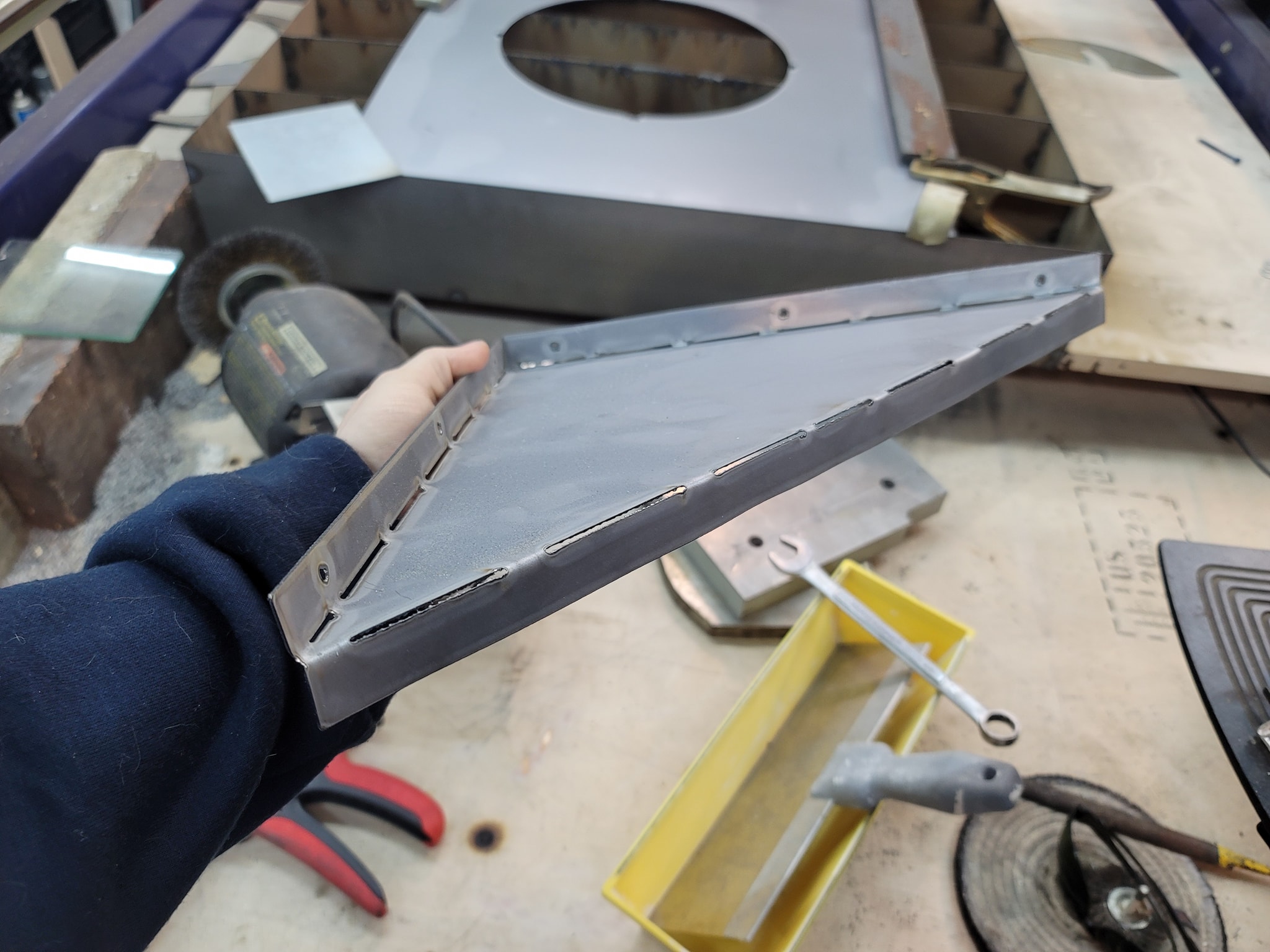

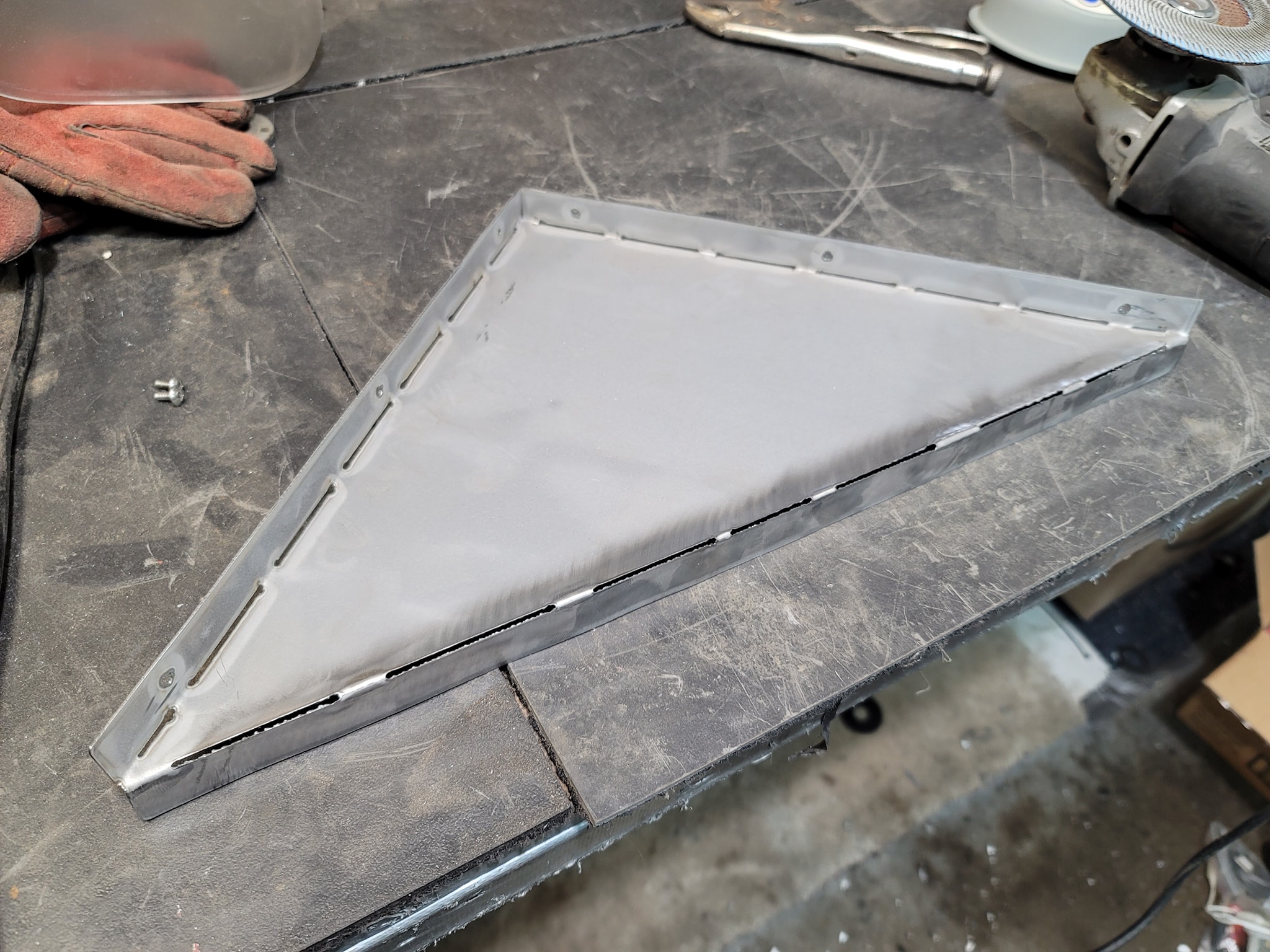

Next was I needed a table for cutting parts on , so used the table to cut out some slats and parts for a box, than welded it up and bolted it to the table, got it shimmed to be perfectly level and bolted in place.

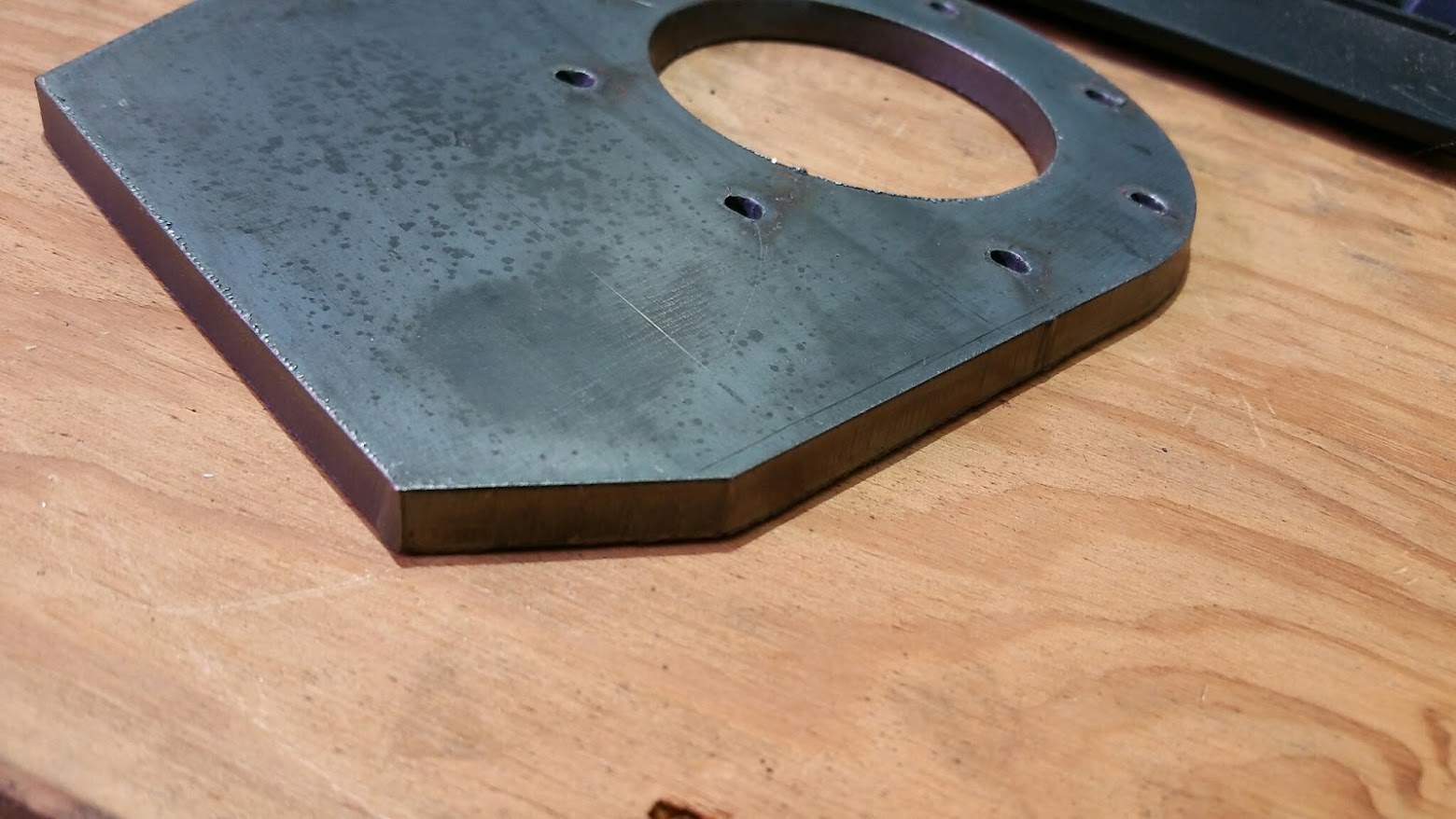

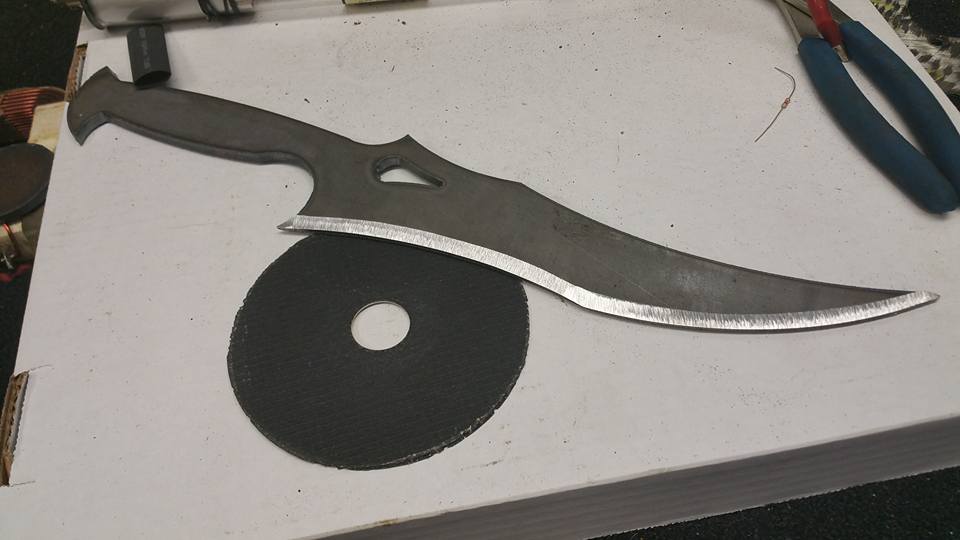

This was a test of 1/4″ material, for an engine mount, so far so good!

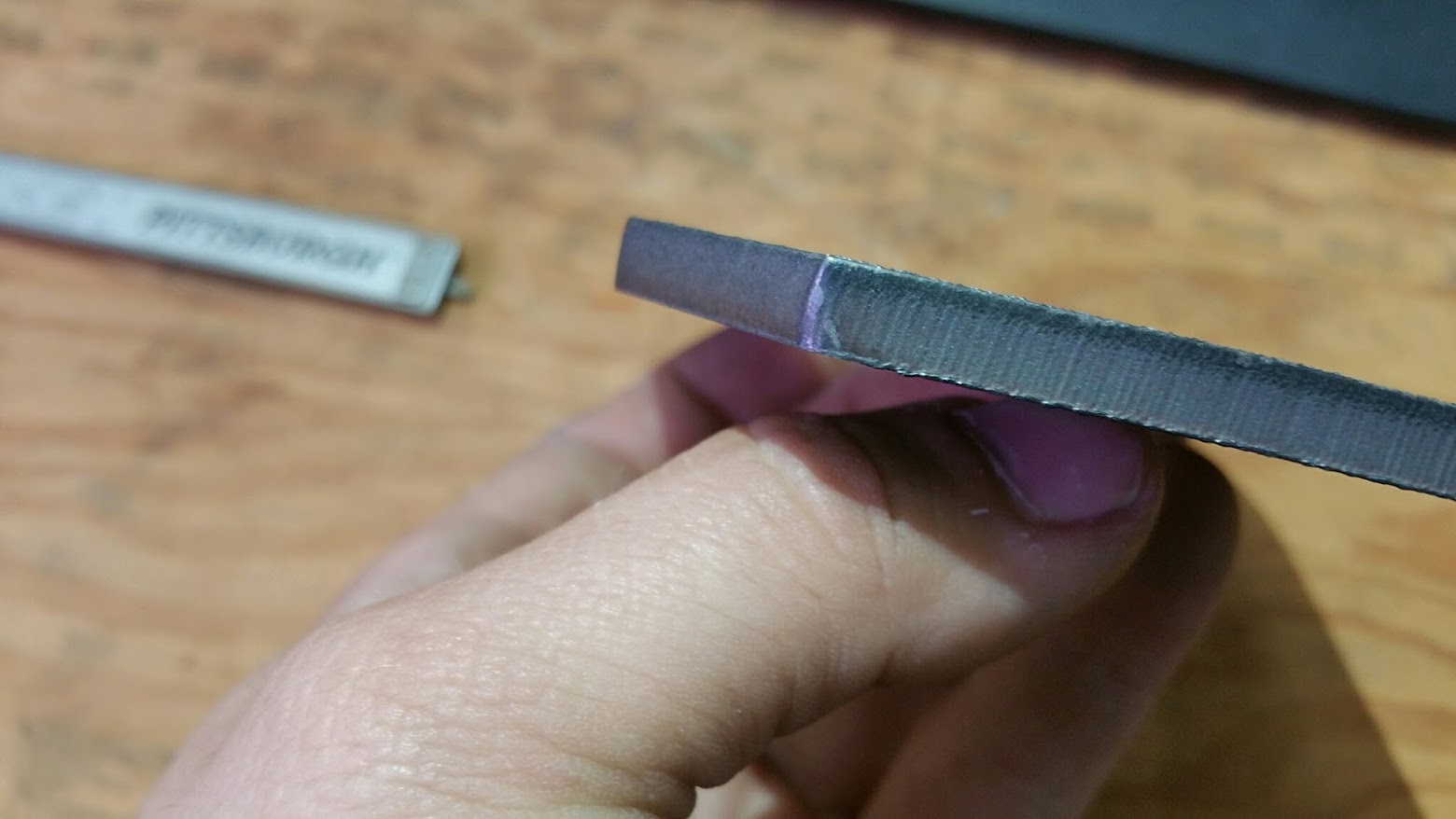

Now the fun part of doing lots of projects to dial in the feed and speeds for the perfect cut quality.

The old vertical torch I had was not the greatest and would not always start the arc. I used an old Dell monitor mount as my torch mount, was slick and had a built in spring relief if I crash. Was the not greatest.

But like I said it did not work well, so I went with the hand torch the Plasma cutter came with, so had to make a new mount for it.

If you want to build your own, here is a full walkthrough of my entire workflow and setup.

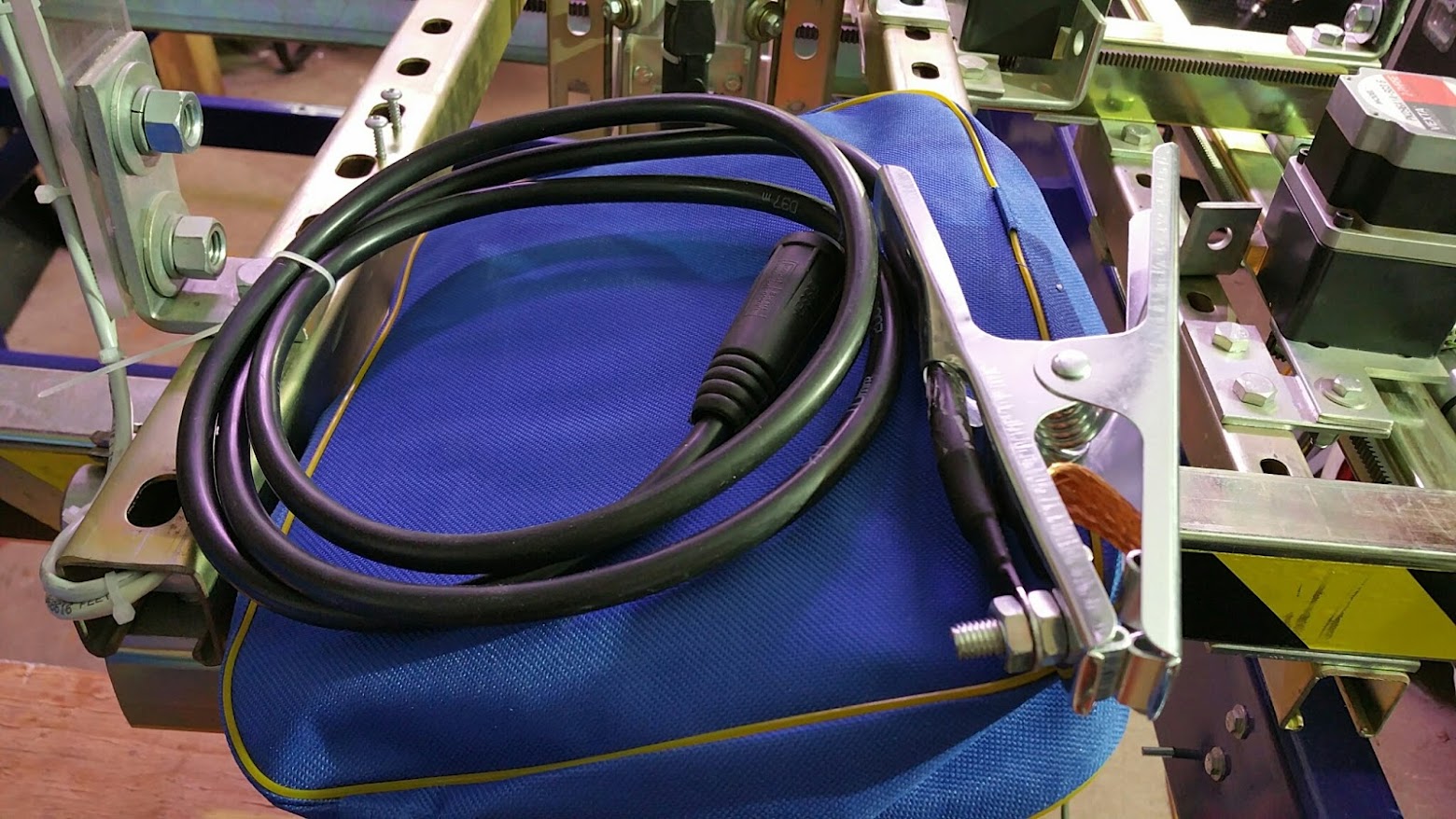

Here is the new mount, built from parts of a high power Xenon lamp holder and High vacuum clamps, gives me a nice solid square mount for the gun, and removable to clean and replace tips.

Much more to come, for this project like many will never be finished, lots of ideas on ways to improve it still.