DC7000 Compressor Review

In the Lab for Testing today is the DC7000 Compressor made by AIM Chassis Tech.

Big thanks to Joe Morrow at Chassis Tech!

First impression when this compressor arrived was the size and weight!

The box had staples holding it together and had substantial weight to it.

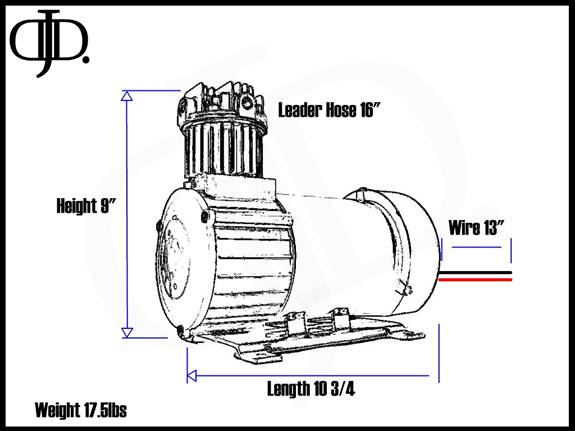

Here are the install specs of the compressor.

The compressor comes in as the largest Oiless compressors I have tested.

In this review I will walk you through step by step as I take this compressor apart bolt by bolt, and through all of the testing results.

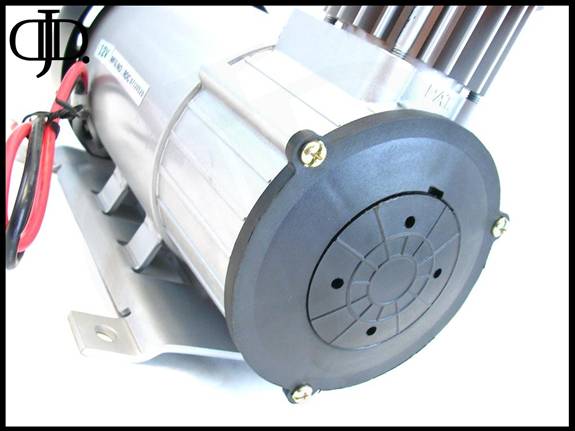

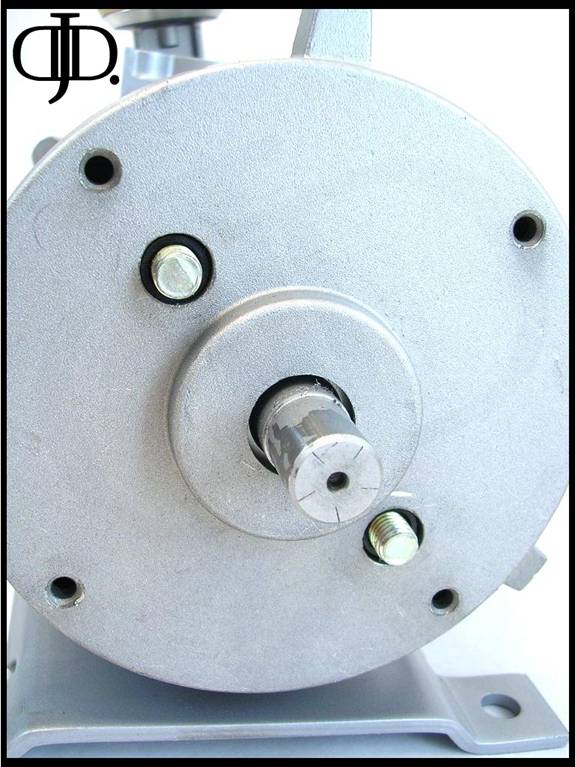

First thing you will notice is the exterior of the compressor.

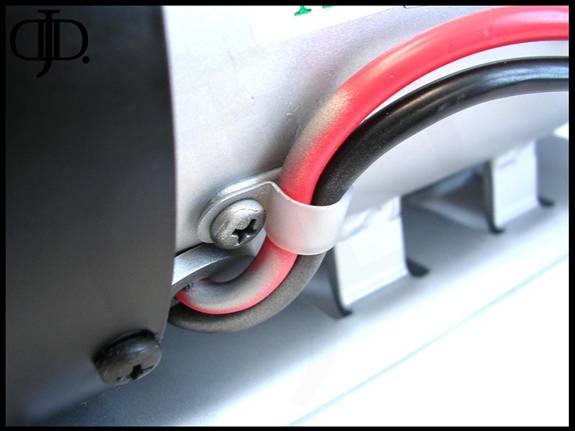

The Wiring on this compressor in contrast to the DC5000* Compressor is much mor functional. The wires are 13” Long from the Body of the compressor to the tip of the terminals.

The power wires are already terminated The only problem I found with this was the Red power wire has a crimped on ring terminal that is too small to fit on the included relay. Or most relays for that matter. Also the Ground has a nice heat shrunk finish detail that the Positive wire does not.

The compressor comes with some parts to get you started.

Here are the included Leader hose and fittings.

The leader hose has two fittings crimped onto it. On the Left is a ¼” NPT male fitting that fits into the head of the compressor. On the right is a 3/8” NPT male fitting that fits into the included check valve (front left) and then (front right) is the included 3/8” male/male nipple to connect everything into your system.

Everything fit together well.

NOTE: make sure the arrow points AWAY from the compressor / leader hose

One thing I want to point out here the leader hose does not have a swivel fitting. This means there is only two ways to attach the compressor to your system,

(1) leave the compressor un mounted and thread the hose into the compressor first then rotate the compressor in your hands while you thread the hose into the tank.

(2) Mount the compressor Now remove the head from the compressor and spin the head in your hand as you tighten the leader hose into the tank.

Either way you do it make sure you use your thread sealant of choice and do not over tighten. On the compressor I tested the Leader hose only threaded into the head with three threads. But it sealed no problem.

The check valve right out of the box had Nicks dings and scratches all over it (even inside). This may have been from bouncing around inside the bag of parts. But it did not look pretty when I installed it.

With that aside the Check valve is large and held back 200PSI no problem. And held tight through all of my testing.

Here is the Relay, this unit is well done and has a great finish on it. As well as large lug terminals for terminating your wires.

The crimp seal on the head of the unit is well done and was sealed tight from the elements. When submerged under water no air bubbles where present.

The solenoid only has one post on top for the control wire from your pressure switch.

What does this mean? Well this means that you can only use a positively switched source for your pressure switch. And the solenoid has to be well grounded through the mounting feet pictured above. So keep this in mind when you install the relay.

Last here is the ‘Short Stop’ External Auto reset circuit breaker. This unit is ratted at 50Amps at 12V and will trip out if the current load exceeds 50amps for more then 6.3Sec. I installed the (copper) lug to the battery or relay side and the (silver) lug to the compressor.

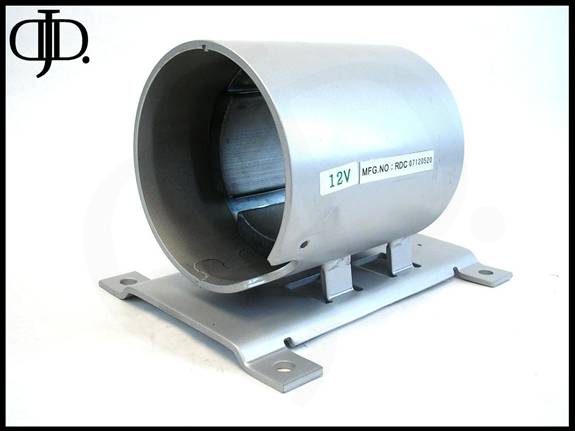

Now that we have gone though all of the Accessories that came with the compressor. Let me go over the finer details of the compressor itself.

The mounting platform is all Steel and has (4) small tabs that are welded to the motor body.

The feet do not come with rubber isolation bushings. But the base is very solid and was easy to mount.

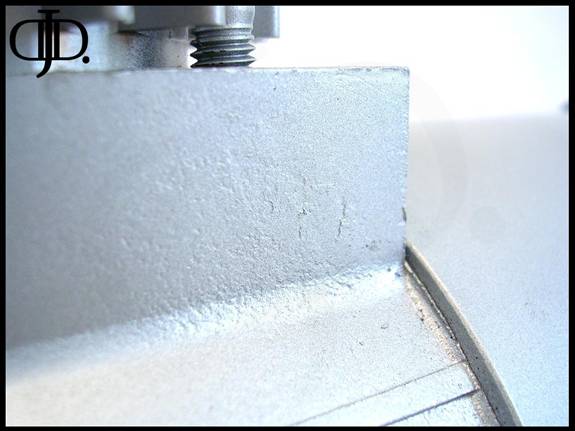

One Slight problem with mine was the base was not square. The compressor rocked on its base. Here you can see the one foot slightly higher then the rest.

NOTE: This is not a big deal once you tighten the mounting bolts you will have nothing to worry about.

On the front of the compressor is a plastic front cover over the crank case. In the center of this is a small 2.5” diameter plastic circle with a small indent for a standard screw driver. Insert the screw driver and gently pry out and away and the filter door will pop free from the case.

The filter is a hard foam like substance ( has the feel of Styrofoam) and is held in place by friction from the four plastic posts. It is very easy to pop off remove and clean.

When you remove the (3) Gold screws on the crank case cover everything will pop apart for easy service and cleaning.

The seal between the Cover and the crankcase was a white thin gasket.

The cover also has small reinforcement ribs on the back side.

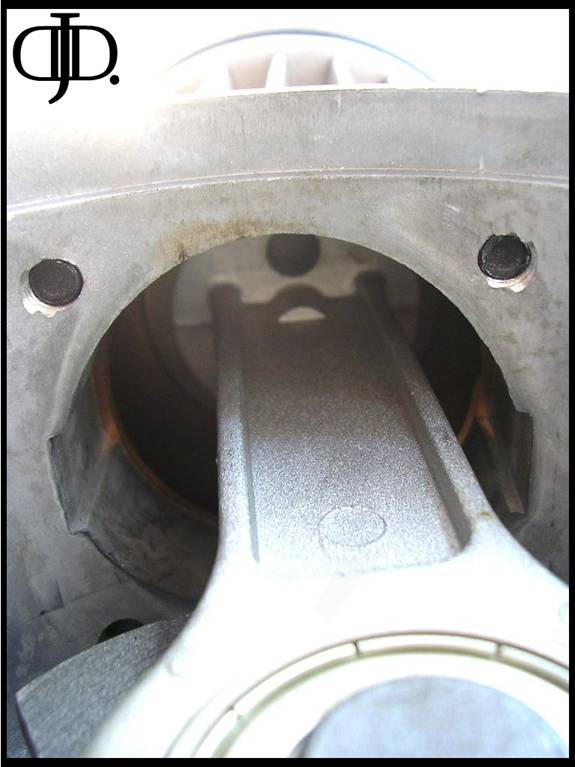

Here is a shot of the inside of the crank case.

Everything in here just like the rest of the compressor is over sized. The counterweight piston and bearing are all large and beefy.

The counterweight is not broken, it simply has a slot machined out of it that is used to tighten the counterweight/ crank shaft to the motor.

The bearing in use is a nice high speed bearing out of Taiwan. With an all metal seal gasket. I also noticed a small spacer on the piston crimp joint, my guess is this is used to adjust for slight casting deviations.

Last when used with a strobe a scope. The bearing and snap ring did not move they remained in there locations throughout the pistons travel as well as under load.

This means that everything is snug and within tolerance.

Here is the outside wall of the crankcase. The casting although rough was solid and with no cracks in the body or mounts.

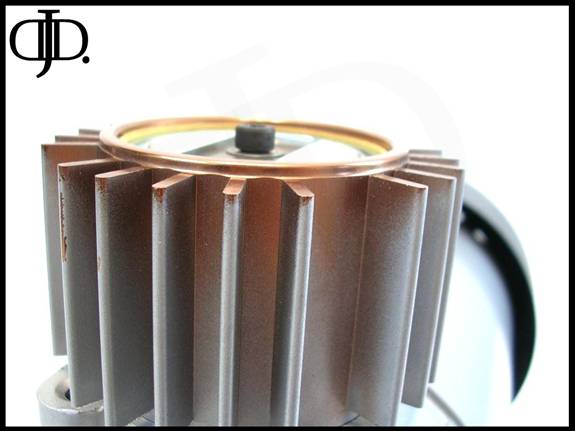

The head of the compressor was a very rough casting that also had a few paint runs and clumps. With close inspection the head and bolts where painted after assembly.

The paint on the Head bolts was very touchy, looks like just from shipping or handling some of the paint has come off the bolts.

This Was Un called for. The wires coming out of the motor had overspray all over them.

I was able to remove this paint with some cleaner though such as rubbing alcohol.

This really detracted from the overall look of the compressor.

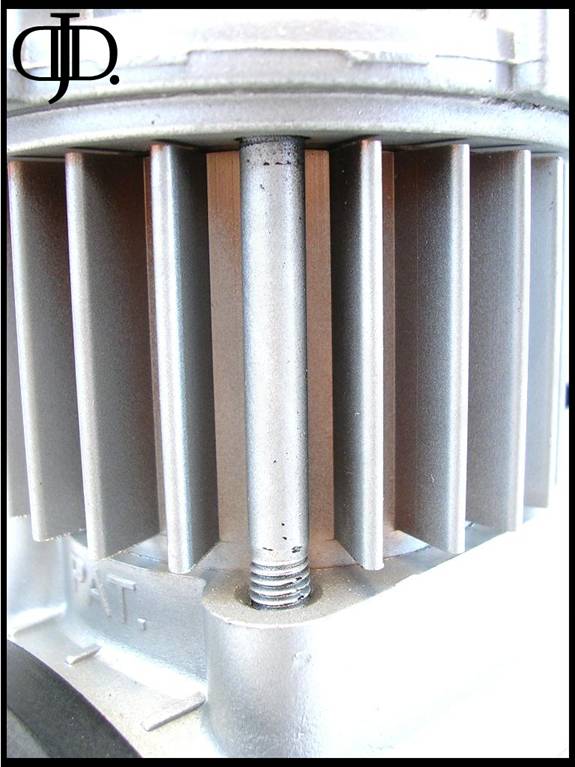

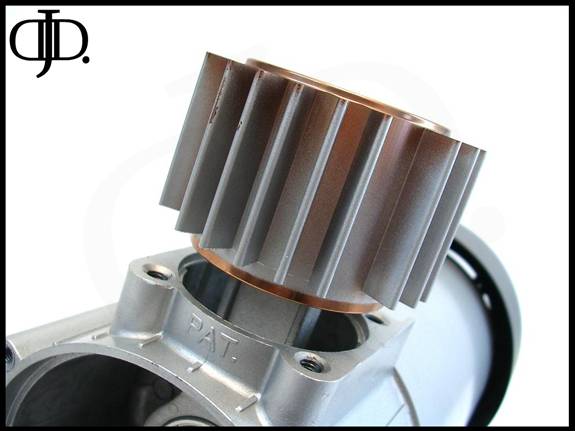

Removing the head exposes the massive piston and solid head.

Here are the head bolts removed. Be very careful with these like stated above the paint is not bonded to these bolts well. It feels to me the bolts shipping oil has remained on them as they where painted. Thus preventing the paint from bonding properly.

The head gasket is a hard material that will have to be replaced if the head is removed after a few years of use. For gaskets tend to bond to there matting material.

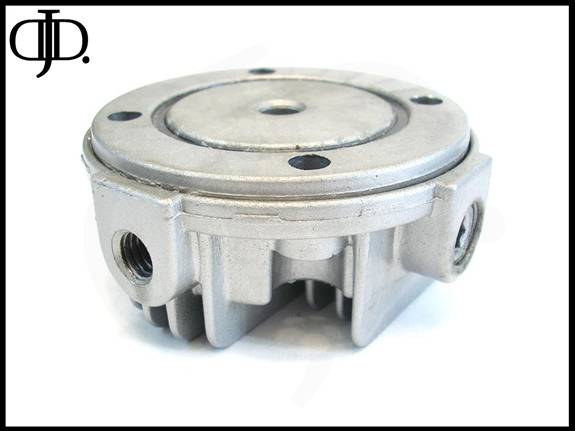

The head is made up of 2 parts the finned head and the valve plate.

The seal for the head again is a small gasket (black ring) in the above pic.

Here is a shot of the head opened up. You will find the large over sized output valve and the underside of the head.

The valve plate is thick aluminum and has the same gasket material to seal itself to the finned head.

The valve itself is actually held in by the finned upper section. The small black metal retainer is just to hold the valve in place when working on the compressor.

The head is very open. First thing you will notice is the ‘U’ shaped metal in the center this is the output valve strain relief, this will prevent the valve from over extending during operation.

A nice feature is the head is tapped for (2) outputs. The far one is the stock output. The Close one with the Allen plug can be used for a second output.

Also far side left is a 1/8” NPT female port that is ready to go just needed drilled, if you wanted to mount a gauge this would be a great feature.

After the head has been removed you can see a very unique valve design, the piston has two valve holes to allow more air through. The single valve covers both orifices. In the above picture the Piston is at Top dead center.

Removing the Cylinder wall I noticed there was no seal between the Cylinder wall and the crank case. This can allow moisture and dust to get into the crank case and bypass the filter.

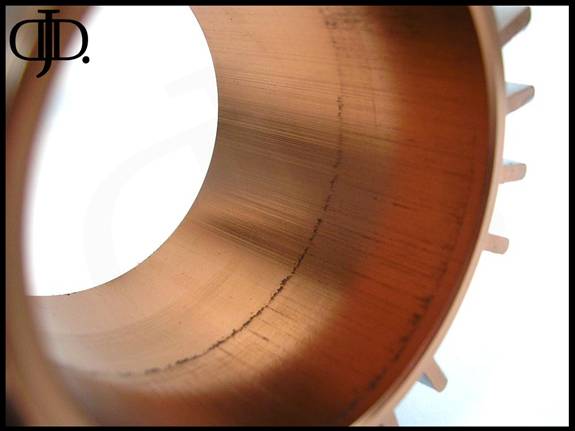

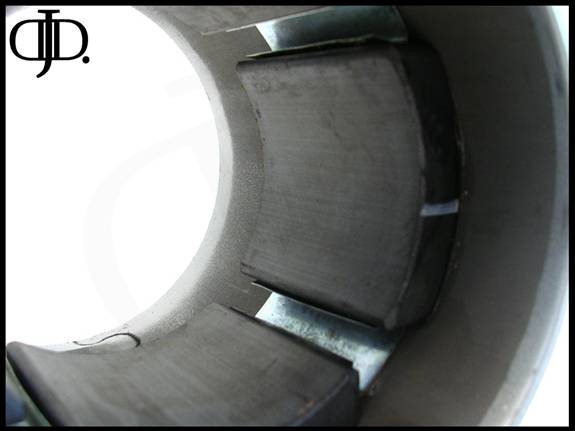

With the cylinder wall removed. You can see the cylinder wall is hard anodized aluminum to prevent wear.

But for some reason this beautiful cylinder wall has been painted over. It does easily flake off. I had to be extremely careful handling this unit as to not scratch or nick the paint.

The inside surface of the cylinder wall even after my testing remained extremely smooth with little sign of wear.

The inner groves although slightly raised where in the direction of travel so they did not effect the pistons seal.

NOTE: if you take this compressor apart mark the location of the cylinder wall and the piston, so the machine marks align up with the wear groves on the piston ring.

The piston ring is your standard Polytetrafluoroethylene composite material. And revealed good wear during testing.

The piston ring is held in by a steel retainer ring that has been crimped into place.

One thing I noticed about the valve was it was loose. It was able to be rocked back and forth. The Allen bolt was tight. My thought was this was intentional, as to why it is needed I am unsure.

Here is a shot of the crank case, the body is solid. Where the cylinder wall and head mount the metal has been beefed up. In the back inside of the crank case opening you can see part of the reinforcement.

The back fan assembly is easily accessible. To remove the back fan cover there are (3) small Philips screws located top dead center and on each lower corner.

The fan is a solid black plastic unit. With a small jam bolt to hold it to the motor shaft. I had no problems removing this.

One thing worth pointing out, right side of the pic you will notice (2) fins are thicker then the rest, this is a way to balance the fan with the added weight of the bolt for retaining it to the motor shaft.

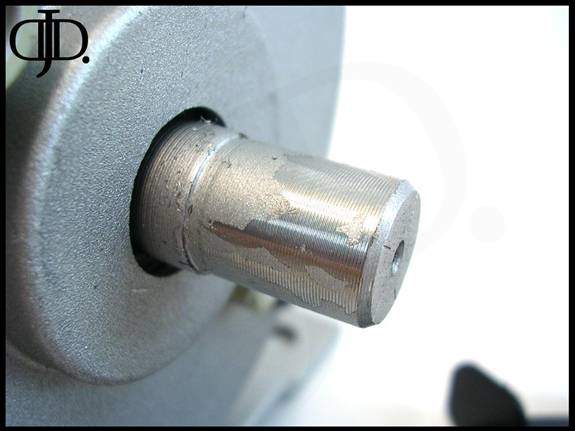

Looking at the motor shaft I noticed some Paint missing so I took a look at the fan.

Sure enough the Paint was on the inside of the fan. This shows me the compressor was assembled while the paint was still wet.

This is not a problem, but may make taking the fan off, a little harder.

After removing the shroud and the plastic fan you will be left with what is above. A solid metal end cap.

The (4) small black/silver screws hold the rear and cap and front crankcase together. The large gold nuts hold the brush assembly to the rear cover.

Again the Paint does not bond well to the screws.

Here is a shot with all of the Bolts and Nuts removed. The Brush assembly is isolated electrically very well from the Chassis. You can see the Gold studs have insulation bushings just like an alternator. The only problem is the nuts on the back side will pass any shorts through to the Motor body.

Remove both the (4) black screws and the (2) gold nuts. NOTE: these may be very tight.

The motor’s rear bearing is also of nice quality, similar to the piston bearing.

The brush holder was then easy to remove. I simply had to remove the small plastic wire retainer and slide everything out and away. This makes it real nice for when you have to service the brushes.

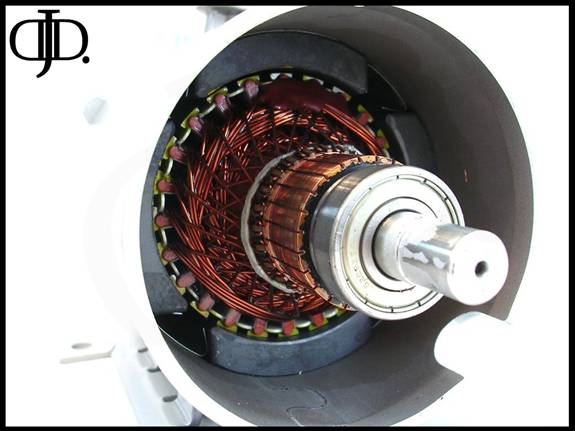

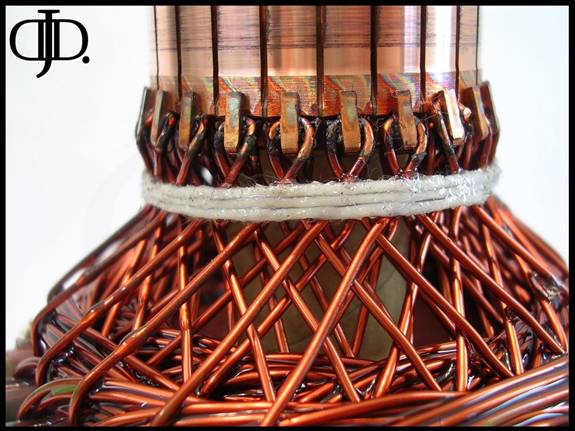

This part I was amazed with. It was nicely done. It is a (4) brush DC motor. You do not see that on almost any of the smaller oiless compressors. This evenly distributes the load across (4) brushes as apposed to (2) normally used in most compressors.

The brush holders and guides where all metal. Even the tension springs where of nice quality.

And if something where to go wrong, you can simply replace just the above part with very little hassle.

Here is where the compressor really shined to me. The motor armature was very well crafted.

I was very impressed with the construction of the motor itself. Everything from the wrapping of the motor down to the use of high end bearings front to back. Take a look at the (4) mounting points on the inside of the crank case, I will talk about these later.

The commutator showed signs of wear even before I tested the compressor. This tells me the motor is at least tested at the factory before it is shipped out. Although there are signs of uneven brush wear, the motor is brand new, and this is normal until the brushes fully break in.

The motor housing is a thick ¼” steel and welded firmly to the base plate as shown earlier.

The motor consist of (4) massive ceramic magnets. The (4) gaps are where the mounting bolts pass through.

Here is the entire compressor all taken apart. This unit consist of allot of part. By far the motor is the best constructed part of this compressor.

Now onto testing!

The compressor with its plastic front cover allowed the air filter to remain almost at room temperature as the compressor was running.

Although the wires did heat up. The amp draw of this compressor was well within the rated spec for that size and length of run of the main wires.

NOTE: Thermal Imaging results coming soon. Please check back here.

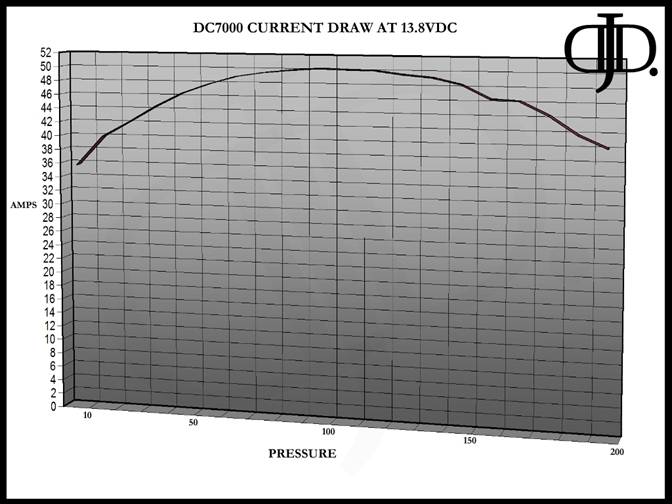

Above is the recorded current draw of the compressor filling a 5 gallon air tank from 0 to 200PSI

Max recorded current draw was 50.2 Amps at 100PSI

Max Peak* Current was 293Amps for 1/100th of a second.

The above is a picture of my anechoic chamber; chambers such as the one above are used to measure the sound pressure levels of an object. The chamber will remove all traces of an echo. Similar to being outside with no walls for miles floating in mid air.

The room has an effective ambient db level of 0db.

The compressor was tested in the above box at 13.8VDC at 100PSI the compressor produced 89db in the A weighting at 1 foot at the loudest point on the compressor.

This compressor ran much smoother then the DC5000* compressor and only a slight vibration was detected during operation.

NOTE: Vibration when mounted to sheet metal can and will cause excessive noise. Hence why most people find this compressor louder then others.

FLOW RATE!

Ok now here is the part you have all been waiting for in this review I am sure.

The flow rate of this compressor at 13.8VDC was 2.085 CFM at 140PSI

This puts the compressor faster then the Air-Zenith that is 1.24CFM at 140PSI as well as the Viair 480C at 0.92CFM at 140PSI.

There have been so many claims as to this compressors performance in the past from people who have had them. It is nice to finally put this to rest and know that this compressor truly is as fast as those have clamed it has been in the past.

How would I rate this compressor?

This is a real tough decision for me on this compressor. This compressor is fast solid and has a well built motor. But the fit and finish of the compressor leaves allot to be desired.

RESTART!

With a slight ( by slight I mean fractional CFM ) Leak I was able to get this compressor to reliably restart at 200PSI!

This compressor has a stronger motor and this was evident in both the current draw and restart ability.

The compressor is rebuild able, but instead of ‘O’ rings the compressor relies on gaskets. As we all know gaskets in time bond with there matting material and cause the gasket to rip. So when you rebuild an older compressor make sure you have replacement gaskets on hand.

For a Rating The only thing keeping this compressor from hitting 10/10 was the Fit and finish of the unit itself. The overspray lack of Paint prep and crude castings leads me to rate this compressor a 8/10 The performance was Solid and so was the unit. So this bumps it up in the ranks.

As long as you keep the above information in mind when working with this compressor you will have a great experience with it.

Cheers,

~Doug

* DC5000 Compressor Review is located here,

http://www.djdlabs.com/DC5000.htm

© 2008 DJD Laboratories

If you have any questions please E-mail DJD@DJDLabs.com

All pictures and information depicted on this page are the sole intellectual property of Doug DeHaven and no information presented on this page can be held against Doug DeHaven in the court of law.