It is not every day that you get to lay your hands on a legend! For one of my first review for Ride Tech ( formally Air Ride Technologies) I will be testing out the Big Red valve manifold. This valve has become a true legend after coming into its own building apon the strengths of its father the ride pro valves.

First some history. 6 years ago I bought a used air ride setup from the internet. The kit was used hard on a daily driver for over 4 years before I got it. Everything was well warn but still working. The ride pro valves that the kit came with where in sad shape, very corroded and the wires very short. I was certain they would not work. To my surprise not only did they work they worked flawlessly! They did not leak pop, stick, or malfunction even once. I had these valves on my truck for well over 3 years and in harsh northern climates. I drove the truck every day and they valves where mounted under the truck. The valves have since been sold and the new owner has had them on his truck till present day, still with no problems! What tell you this story? Well there is no way better to explain the absolute backbone of Ride Tech products, Reliability. They have built there reputation on creating products that can out perform any on the market, and can do it in the most adverse of conditions day in and day out without and problems.

When I sold the ride pro valves I upgraded only for speed I went with the standord ‘brass’ valves you buy individually and hoped for the best. For the Big red valve was fairly new at the time and was very expensive. I had problems with leaks and freezing that today I know I would not have had to worry about had I gone with the Big Red valves.

The Big red valve is an exact copy of the Ride pro valve system just double in size. Every aspect of the ride pro system has been upgraded and beefed up for faster valve operation.

The one thing that kmept me as well as most of you from picking up this valve for yourself was the cost. Not to mention there where very limited reviews online to its operation. My the end of this review I hope to make you a beliver.

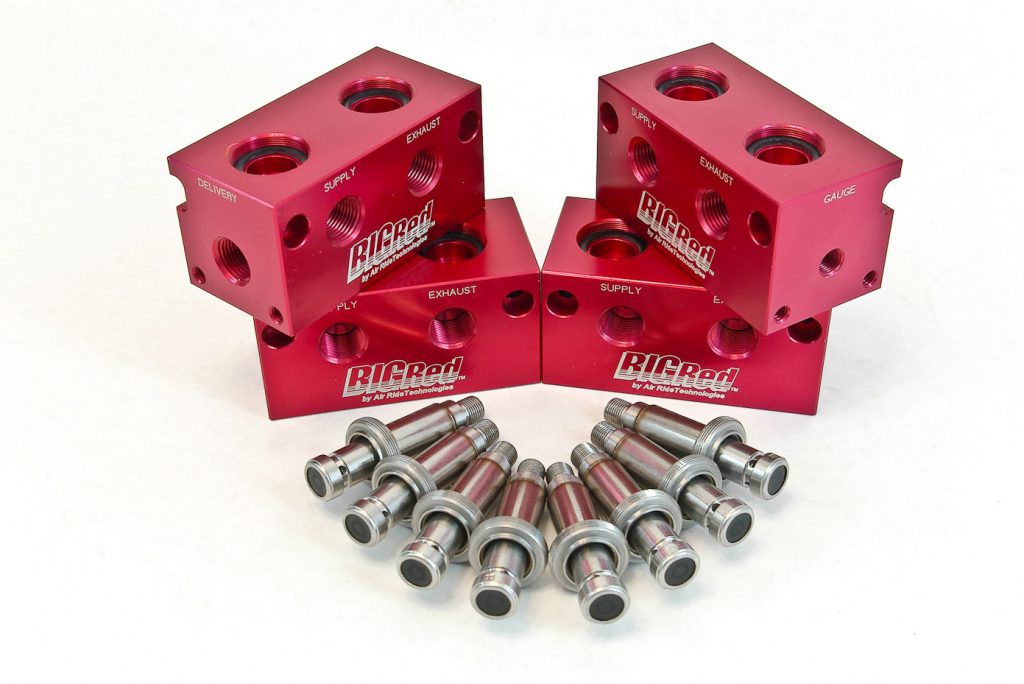

The quality that comes with the Big Red valves lives up 100% to the reputation it has earned over the years and to the standard you come to expect from a company like Ride Tech. Every aspect of this valve is made with the utmost highest quality components. For no part of this valve is an ‘off the shelf’ item. Each part is designed and manufactured specifically for air ride use. The main valve manifold block is 6061T6 Aircraft grade aluminum that has been precisely machined to produce an almost mirror like finish. The entire valve is hard anodized for both the trademark Red color and unheard of durability.

The dynamic parts of the valve also have care taken to there operation. Ride Tech did not take on the enormous task of designing a valve from scratch. They enlisted the help of one of those most respected names in the pneumatic industry Parker Hannifin For Ride Tech worked with Parker to develop a special pilot section to work with the Ride pro manifold. Through decades of experience from Parker in Valve operation and the years decades of experience in air ride control from Ride tech led to the marriage of a truly amazing valve structure. The integral plunger like most valves has a rubber seat that seals the air from passing. Ride tech and Parker when the extra step to develop a ‘top secret’ special rubber compound not found in any other Air ride valve. This special compound does something unimaginable. It makes the Valve bubble tight. This term gets thrown around allot, but through my testing I was able to verify no leak at all. Yes you heard me correct 99.9% of every valve I have tested will leak some way or another. For in industry ( where most valves come from) the need to be bubble tight is not needed. For no equipment is left on of off long enough for the very slight pressure drop to be noticeable.

So testing this aspect was an interesting adventure. For I had to perfectly seal a single ported tank with only a pressure sensor to the Fill port of the Big red valve. Everything was Liquid thread sealed. I pressurized the system to 150PSI and left it sit .. and sit.. and sit. I kept waiting for the pressure to drop even 1/10 of a PSI so I had a number to work with to calculate the leak rate. To my surprise there was none. I had to continue with testing so I stopped at the 2 Week mark. And to my surprise the pressure was still at 150.0PSI Granted the tank and valve where kept and a constant temperature throughout the test. This gave me no number to divide by so Without a many month long test I am going to have to say Ride Tech truly does hold up to the ‘bubble tight’ status.

For the Sceptics I did in fact immerse the valve manifold ( no coils) into a tank of Alcohol to look for any bubbles. None where present. ( Why alcohol? ) For the fact when I remove it from the tank the residual liquid will evaporate away. And the Valve is clean to boot 😉

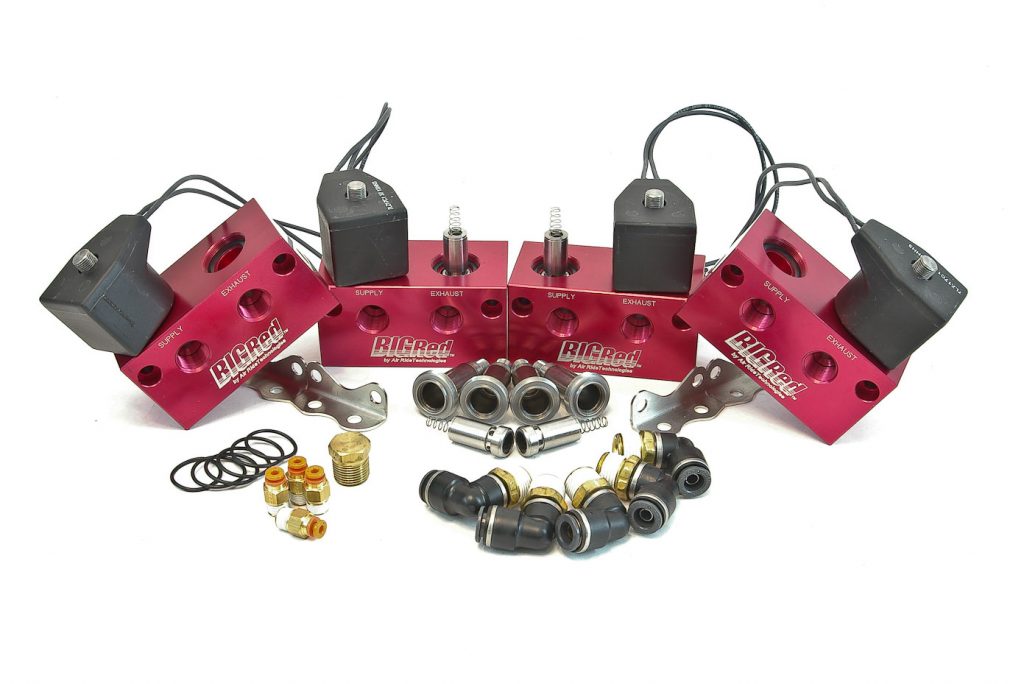

The coils used on the valve are a standard weather tight Parker coil. Same one used on the valves once sold to the air ride industry.

This coil pulling slightly less then 0.47 amps has more then enough power to pull open the valve even at well beyond its ratted pressure at my tested 200PSI The coil has built in sealed wire leads that are professional terminated into weather tight OEM style connectors. The grounds are crimped and heat shrunk/glued into there connectors allowing for a weather tight seal from the elements. These connections are extremely robust and painstakingly simple to connect up. The only problem that bugged me was they took away from the clean look of the valve. Keep reading below to see how I combated this.

When in operation the valve has a crisp click on and off the solid ‘thunk’ as it opens gives you a warm feeling inside that you know this valve is solid and working perfectly.

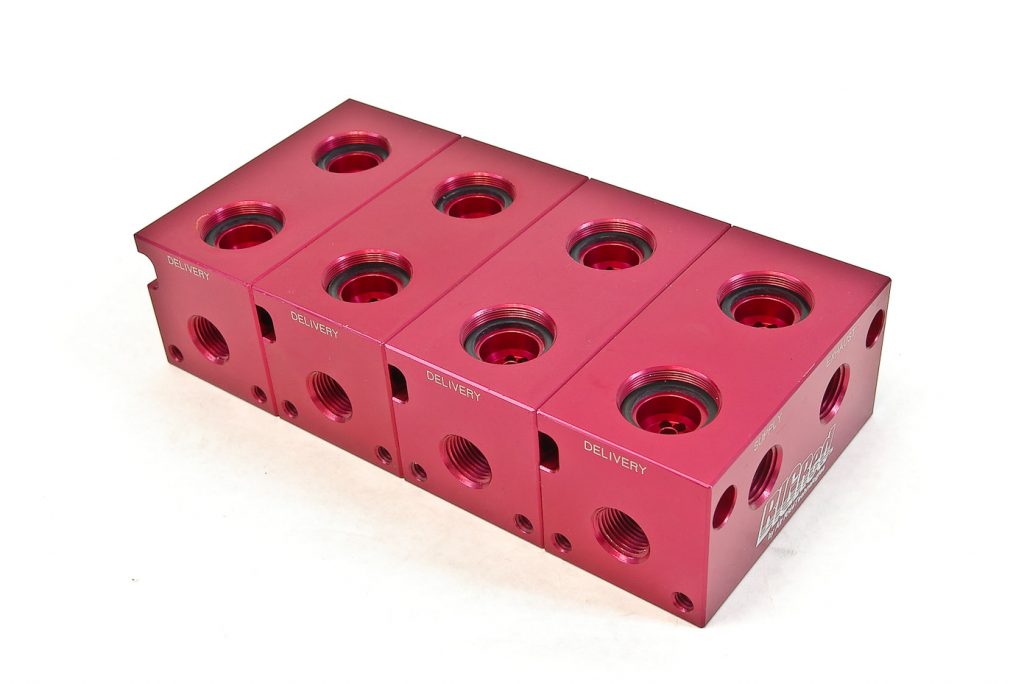

Going back to the manifold itself you will notice something unique about its looks. The lines that bisect the block allow the valve to be broken apart into small ‘per corner’ sections. This will allow you to install each valve at each corner of your vehicle for ease of installation as well as sped up flow rates.

The way the valve is divided leads to a creative way to joint them. Two body length hardened Allen bolts sandwich all of the sections together with small rubber o ring sealing of each passage way. No need for fittings or sealants. So down the road it is easy to break it apart or join it together with ease.

The o rings used to seal the upper pilot section to the base are very unique, they are not your standard round O ring they have a unique flat washer design, this design will prevent the normal O ring failure usually associated with that design that is when constantly squeezed the ring will eventually deform, this can cause the ring to no longer conform properly and seal as needed. With the flat washer design the surface area is increased and the removal and replacement of the pilot for cleaning will not jeopardize the seal of the valve.