Have you ever wondered how trains stay on the tracks and navigate curves so effortlessly? At first glance, you might think the flanges on the edges of train wheels do all the work, but the real magic lies in the wheels themselves—and I’ve designed an exhibit to show exactly how it works.

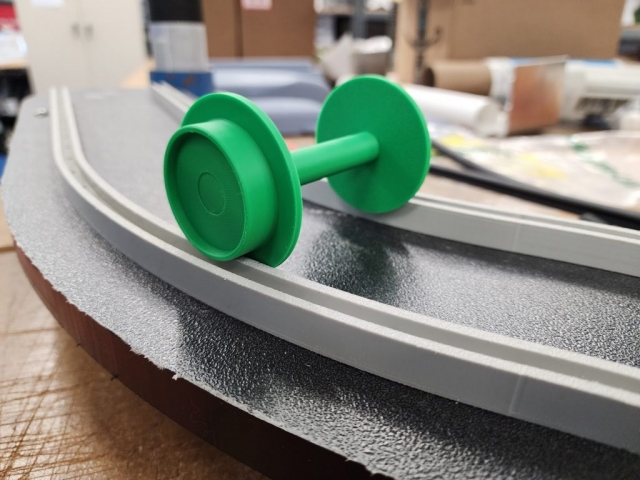

The centerpiece of the exhibit is a ramp with a gentle curve, and two sets of scaled-down train wheels. One set features flanged wheels that look just like the ones you’d find on a real train, while the other set has conical wheels designed to replicate the actual geometry used in railway engineering. As the wheels roll down the curved ramp, the difference in performance is striking.

The flanged wheels get stuck, unable to navigate the curve without intervention. In contrast, the conical wheels self-adjust, shifting their effective wheel diameter to match the curve. This adjustment allows the train to glide smoothly along the curve without getting caught or derailing. It’s a simple but elegant demonstration of how real trains auto-center themselves on tracks, reducing wear and tear on both the wheels and the rails.

The flanges, it turns out, are just a backup feature, kicking in only when the curve is too sharp or the train is traveling too fast. For most situations, the conical design does all the heavy lifting, keeping trains running efficiently and safely.

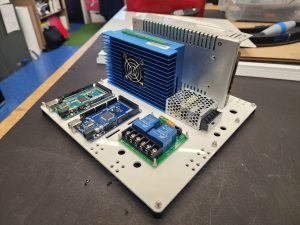

Building this exhibit was a fascinating process. Every component was designed and 3D printed in-house, with countless iterations to ensure the wheels behaved as they should. I even dusted off my old calculus books to calculate the ideal ratio of cone radius to ensure the wheels could negotiate the curve properly. It was a rewarding challenge to balance the mathematics with the practicalities of building a working scale model.

This exhibit not only demonstrates the physics behind train wheels but also highlights the brilliance of an engineering solution that has stood the test of time. It’s a tribute to the innovation that keeps the world on track—literally!

Printed everything on our new Bambu Labs P1 S printer.

The next step, is everything was sent out to be printed in Nylon 12. Black. Excited to see how it all looks. Once they come in, and everything is installed, I will update this post!

Proof not evrything goes by the book, The flaged wheel on paper should not be able to navigate the curve, but it found a way ha!