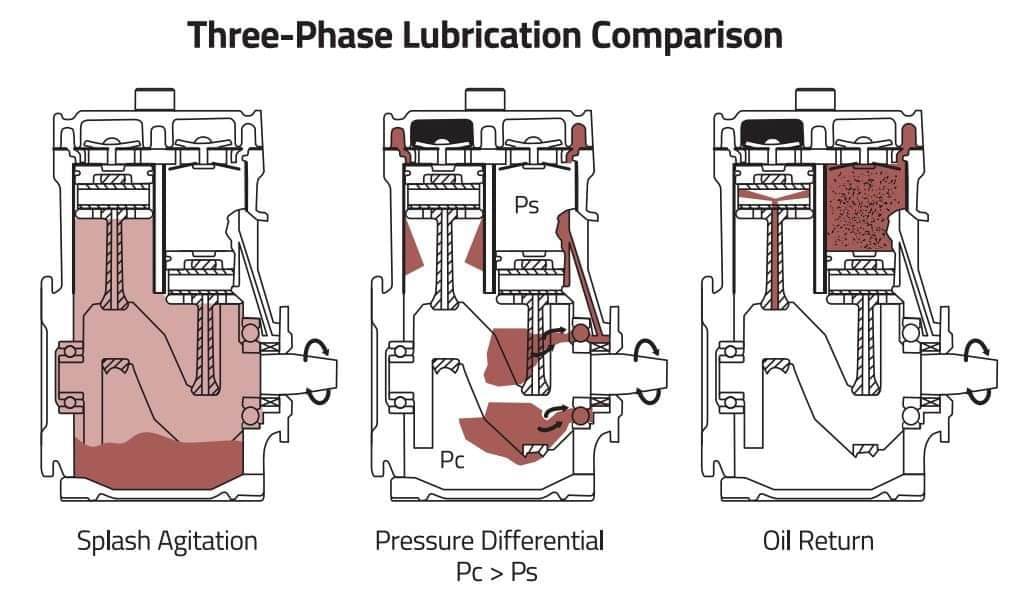

Here is a cross section of a York EDC compressor, showing the oil passage.

SPLASH AGITATION: This is normal operation, the movement of the crank splashes oil internal to the crankcase to allow all parts to remain lubricated. The oil level will always climb the side of the compressor that the bottom of the crank splashes in that direction. ( More on that bellow )

PRESSURE DIFFERENTIAL: This is special to AC use, for in an air conditioning system, the inlet is still under pressure, more than that of the crankcase. When oil ends up in the AC lines, it will return via the suction port on the compressor, this will be forced through the front passage and return the oil to the crankcase. NOTE: This part only happens when the PC ( Pressure Crankcase ) is greater than the PS ( Pressure Suction ) A slight bit of oil will be sucked up from the crankcase and blown into the intake to maintain slight lubrication of the valves and head. this only happens for a very brief moment at the bottom of the suction stroke, if there is no oil already in the suction side to return.

OIL RETURN: Under the compression stroke, any oil around the piston rings is pressed back into the crankcase.

Why does this all matter? When used as an AIR compressor, the system changes in one important way, the suction side now is at 1 atmosphere of pressure and under suction can drop to vacuum levels. This can cause oil to be pulled from the crankcase on almost every stroke. The smaller your filter, or more restrictive it is, the more of a vacuum it will pull, and cause more oil to be sucked in and blown out.

How to prevent this problem,

- Get the largest free flowing filter you can for your inlet. ( think valve cover breather size ) These compressors can move 6CFM at 140PSI of air, so the filter on your large shop compressor is an idea of how big it should be!

- Vent the crankcase. Remove the bolt on the side and install a small ‘vent stone’ or air muffler to allow the crankcase to always be at the same pressure as the atmosphere. This will help prevent heat buildup warming the air and expanding pushing the oil out of the crankcase into the head. Note the direction of rotation, and put the vent on the opposite side, so the splashed oil does not reach the vent port.

- This is the hard one, this is blocking the oil passage in the above picture, You will need to remove the head, and look down into the suction port, you will see a small hole that you need to drill and tap for a small Grub screw to seal it off. ( No need for Teflon or sealant ) for a little oil getting by is still a good thing.

This is also why when using one of these for Compressed air use, you want straight weight 30, non foaming oil. the non multi weight like 10w30 prevent oil blow by when it heats up, and the non foaming prevents the oil from getting up into the parts it can leak past faster.

I will fill out this section with photos on doing the ‘oil mod’ soon as I pull the other information from the old archive. Post any questions you may have bellow!

Here is a link to much more info on the Yorks,

And if you vent the crankcase, this may help you check and fill the oil.