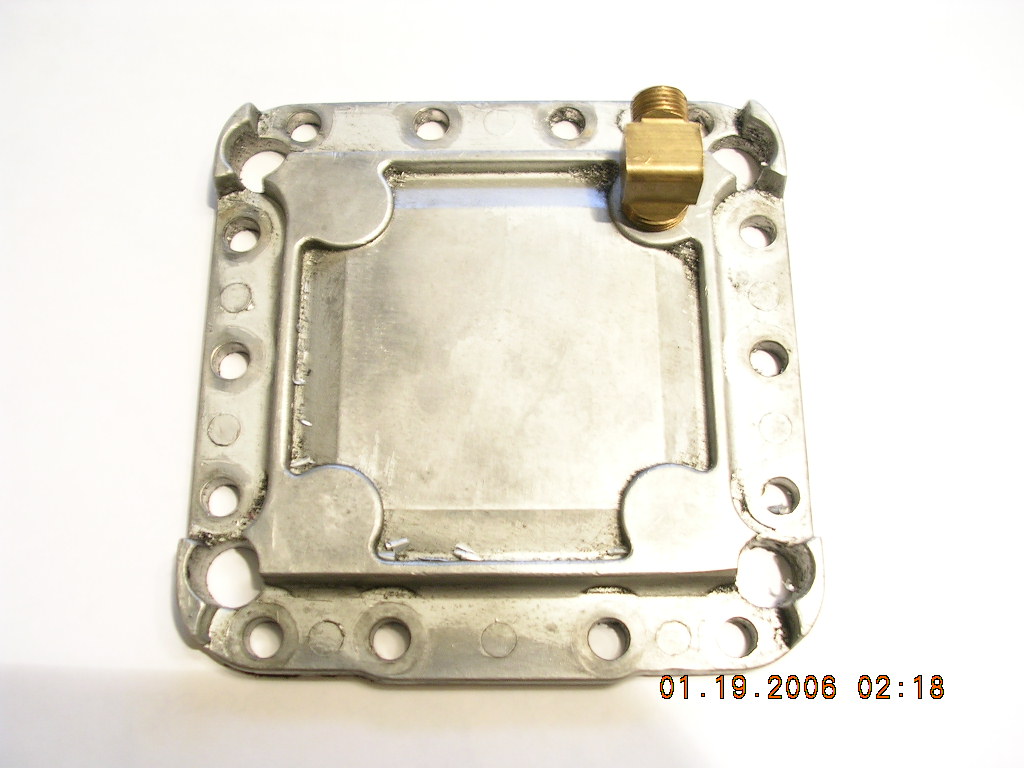

Here is a way I came up with for checking the oil on my EDC. Drill and tap the bottom of the compressor ( With the bottom removed to not get metal chips in the compressor!)

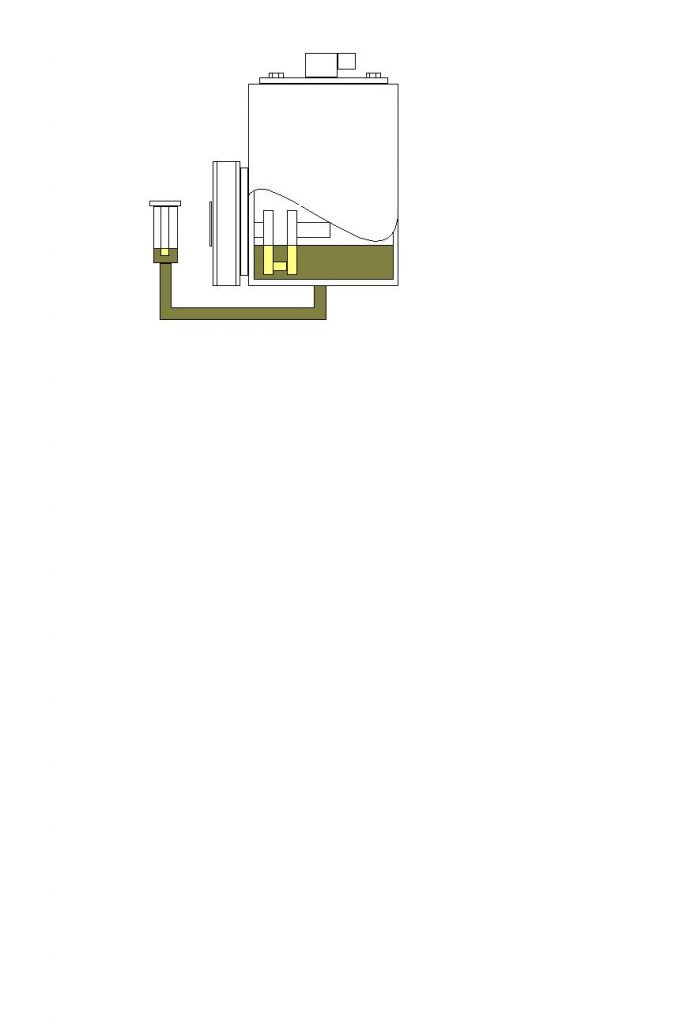

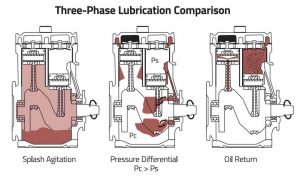

NOTE: You MUST vent the crankcase for this to work, or the moment you fire up the compressor it will pump all the oil out the new pipe!

A ball valve set to be the exact height of the oil level needed inside the compressor is key, just open the valve and look down if the oil was level with the top of the ball I knew I had the right amount of oil. Be sure to add oil slow, it has to work its way through the pipe and in. You can cycle the inner pulley with your fingers to speed it up.

To vent the crankcase, use an air muffler and a thread adapter for the top side oil port, that you will no longer need access to!